27

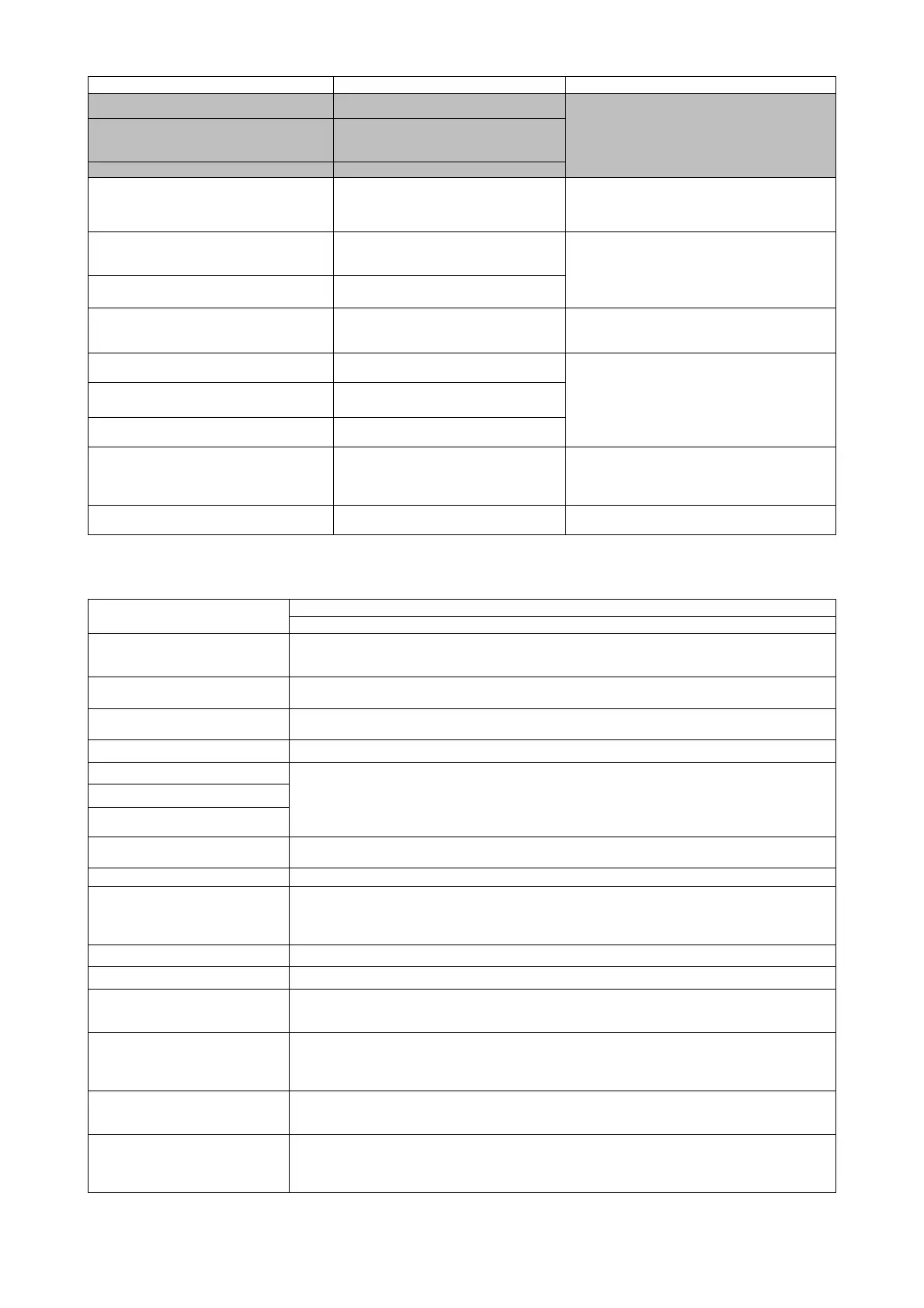

2.4 Forbidden uses

Operation in explosive atmosphere Fire and explosion

Forbidden use

Suction of explosive, toxic and dangerous

gases

Fire and explosion

Environment pollution

Risk of operators health

Operation with flammable service liquids Fire and explosion

Suction of liquids with flow higher than the

limits of the table in the par. 2.1 - 2.2

RVS stall and possible ejection of parts

Install a liquid separator on the suction nozzle

of RVS

Long operation with shut off valve locked

Cavitation

RVS stall and possible ejection of parts

Inform the qualified personnel charged with

RVS

Operation with wrong direction of rotation RVS stall and possible ejection of parts

Operation with speed higher than the

maximum one

RVS stall and possible ejection of parts

Use suitable limits to the electric motor speed

when it is supplied with frequency converter

Operation with pressure P1 higher than

atmospheric pressure

Ejection of dangerous substances

Use a safety pressure switch

Operation with pressure P1 lower than the

minimum one

Cavitation

RVS stall and possible ejection of parts

Operation with pressure P2 higher than

maximum one

RVS stall and possible ejection of parts

Operation with temperature T1 higher

than the maximum one

Overheating

Fire

RVS stall and possible ejection of parts

Use a safety temperature switch on the

convoyed gas

Operation with temperature Tl higher than

the maximum one

RVS stall and possible ejection of parts

Use a temperature switch on

circuit

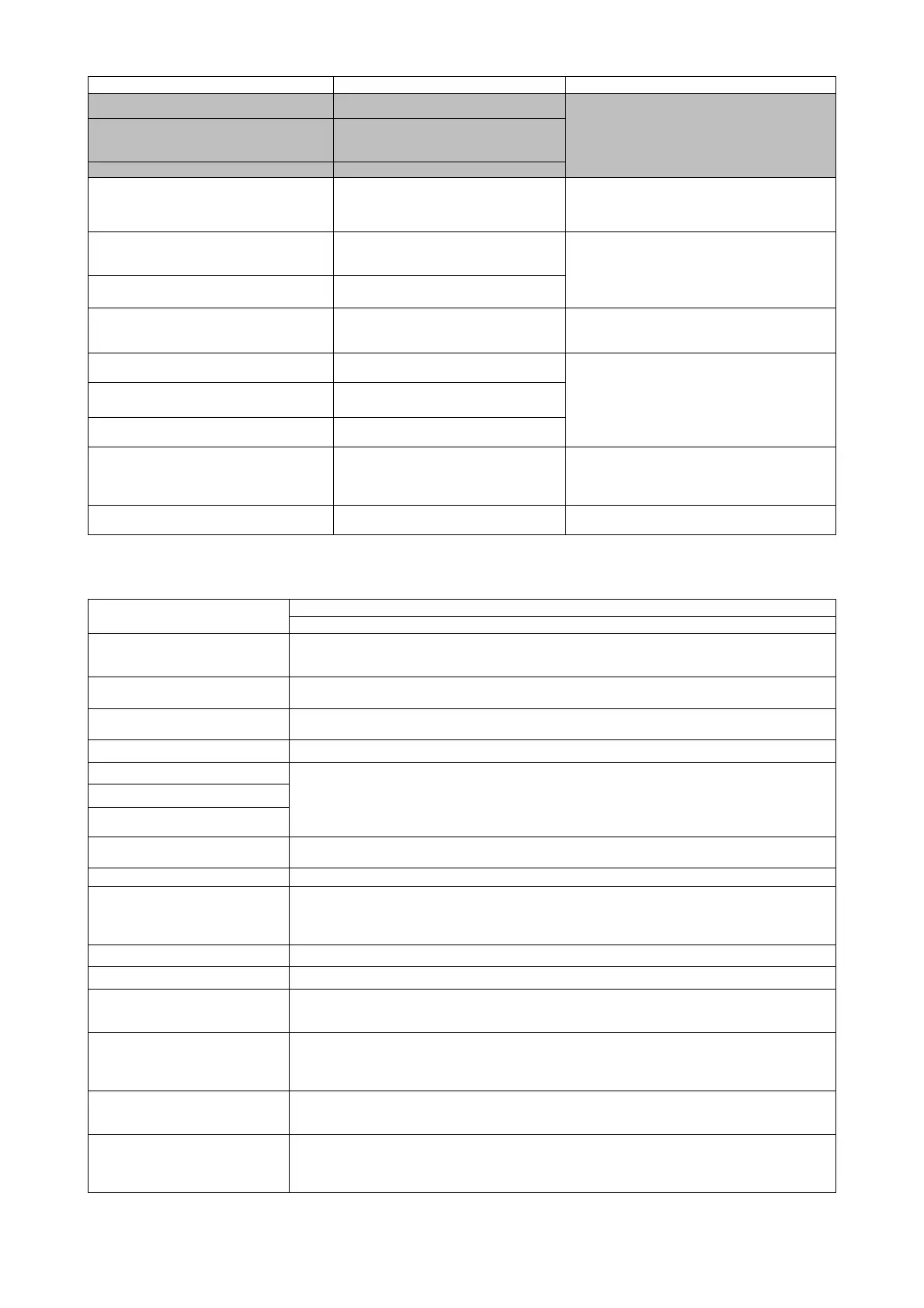

2.5 Residual Risks

Hazard

UNI EN 1012-2 Vacuum pumps

Cutting, severing, drawing in,

trapping, entanglement, friction

and abrasion

None

Fluid ejection

Overcoming the operation limits (par. 2.1 - 2.2) can cause the risk of ejection of fluids

Ejection of parts

Overcoming the operation limits (par. 2.1 - 2.2) can cause the risk of ejection of parts

Install a safety valve on the discharge in case the pump is not discharging to the atmosphere

Loss of stability

None

Electric installation

None

Only for the principal motor supplied directly by ROBUSCHI

Delivery of ROBUSCHI does not include the design of the operating environment where the

pump will be installed, nor the power circuits, control circuits and other controls or equipment

required by the specific function of the pump

Electrostatic phenomena

External influences on electrical

equipment

Thermal safety

None

Noise

None

Radiation None, related to motor and electrical equipment supplied by Robuschi.

Delivery of ROBUSCHI does not include the design of the operating environment where the

pump will be installed, nor the power circuits, control circuits and other controls or equipment

required by the specific function of the pump

Suction of liquids

Overcoming the operation limits (par. 2.1 - 2.2) can cause the risk of ejection of parts

Gas

Forbidden use can cause the risk of suction of dangerous gases

Fire and explosion Overcoming the operation limits (par. 2.1 - 2.2) can cause the risk of fire and explosion

Operation with shut-off valve locked can produce the risk of fire

The not correct maintenance can cause the overheating and the risk of fire

Failure of energy supply None

Delivery of ROBUSCHI does not include the design of the operating environment where the

pump will be installed, nor the power circuits, control circuits and other controls or equipment

required by the specific function of the pump.

Safety Related Measure and

Means

Delivery of ROBUSCHI does not include the design of the operating environment where the

pump will be installed, nor the power circuits, control circuits and other controls or equipment

required by the specific function of the pump

Emergency Stops Delivery of ROBUSCHI does not include the design of the operating environment where the

pump will be installed, nor the power circuits, control circuits and other controls or equipment

required by the specific function of the pump. Emergency button is to be installed on behalf of the

customer.

Loading...

Loading...