30

4.3 Accessories installation

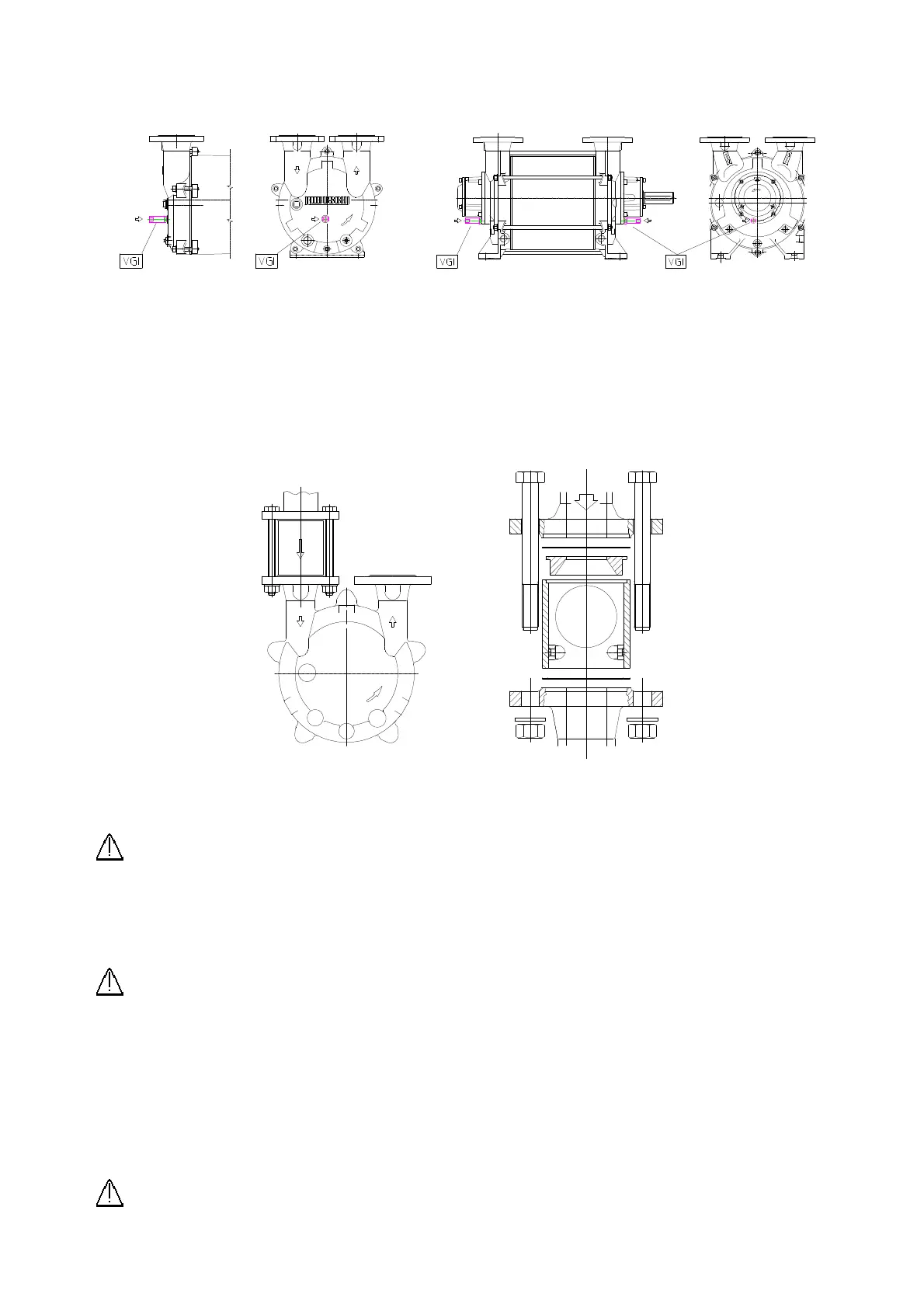

4.3.1 Anti-cavitation valve VGI

The anti-cavitation VGI valve eliminates cavitation problems. It has to be installed on pumps working in vacuum. The valve is effective

when the pump approaches the cavitation field zone (absolute suction pressure less than 100 mbar, hot gases and vapours conveying,

service liquid with high vapour pressure or temperature).

RVS 7/21 RVS 23/60

Fig. 8

Install anti-cavitation valve as shown in fig. 8.

If the gas conveyed must not be contaminated by air, the valve has to be connected to the separator tank, gas side, or to an inert gas tank

at atmospheric air.

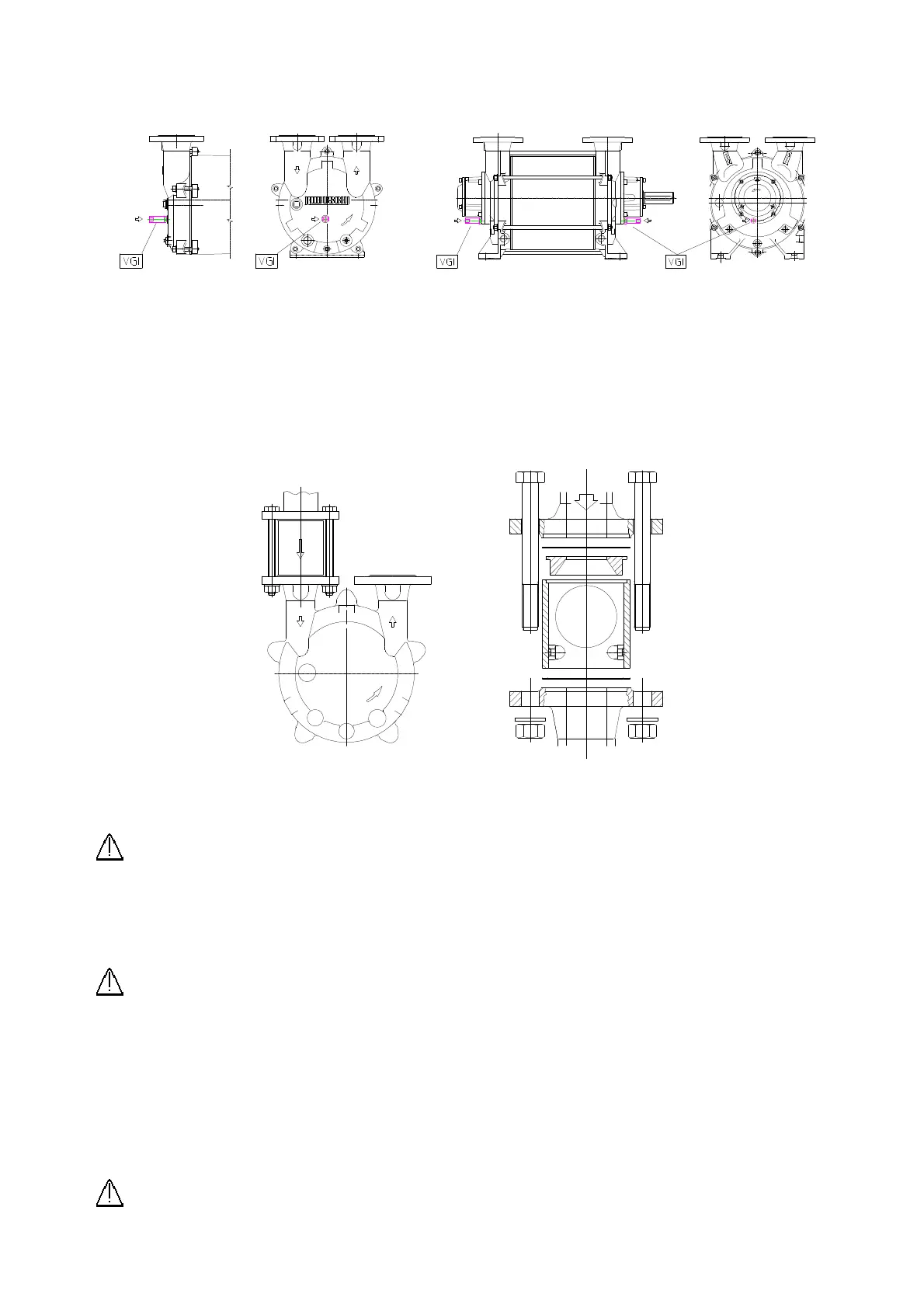

4.3.2 Check valve

The valve insulates the pump from the plant when the pump stops.

The check valve, VAC design, insulates the pump on the suction flange for vacuum operation (see fig. 10) and on the discharge flange

for pressure operation.

4.4 Installation diagrams

During operations, the pump must be continuously fed with the service liquid following one of the two circuits described hereafter.

Robuschi refuses all responsibilities for hydraulic

connections not complying with the law in force

4.4.1 Partial recirculation circuit

In this case the liquid is partially recirculated toward the pump together with some fresh liquid fed from an external source and the remaining

quantity is discharged out of the pump (fig. 1).

Temperature of the service liquid at pump inlet will be higher in respect to the fresh liquid.

The capacity of service liquid for partial recirculation feeding is indicated in section 5.6

Warning: Install the flowmeter 3 to stop t

he pump if the service liquid flow rate is insufficient

4.4.2 Total recirculation circuit

In this case the service liquid is totally recirculated toward the pump without adding external fresh liquid (only make-up equal to the quantity

evaporated during operation (fig. 2)

The heat exchanger 10 provides to cool the service liquid. The pump recirculates the service liquid (in vacuum operation) only if the

pressure drop of the heat exchanger is less than 100 mbar and only if the suction pressure is less than 600 mbar absolute.

For higher suction pressure or if the pump is working in stand-by operation must install an auxiliary circulation pump 9 in the service liquid

pipeline.

4.5 Electric connections

: Before any maintenance disconnect the power permanently

Loading...

Loading...