36

6.6 Electric motor maintenance

Warning : It is not allowed the electric motor dismantling, in case of

maintenance contact ROBUSCHI

or the electric motor manufacturer

6.7 Transferring KRVS

6.7.1 Transferring in the site

Prepare KRVS as described in the paragraph 6

• Strip down KRVS from the plant

• Transport KRVS in the new site following the instruction of paragraph 3

• Install KRVS following the instructions of the paragraph 4

6.7.2 Transferring in an other site

Prepare KRVS as described in the paragraph 6

• Strip down KRVS from the plant

Warning : Contact ROBUSCHI for the relevant transport instructions

• Install KRVS following the instructions of the paragraph 4

6.8 Spare parts

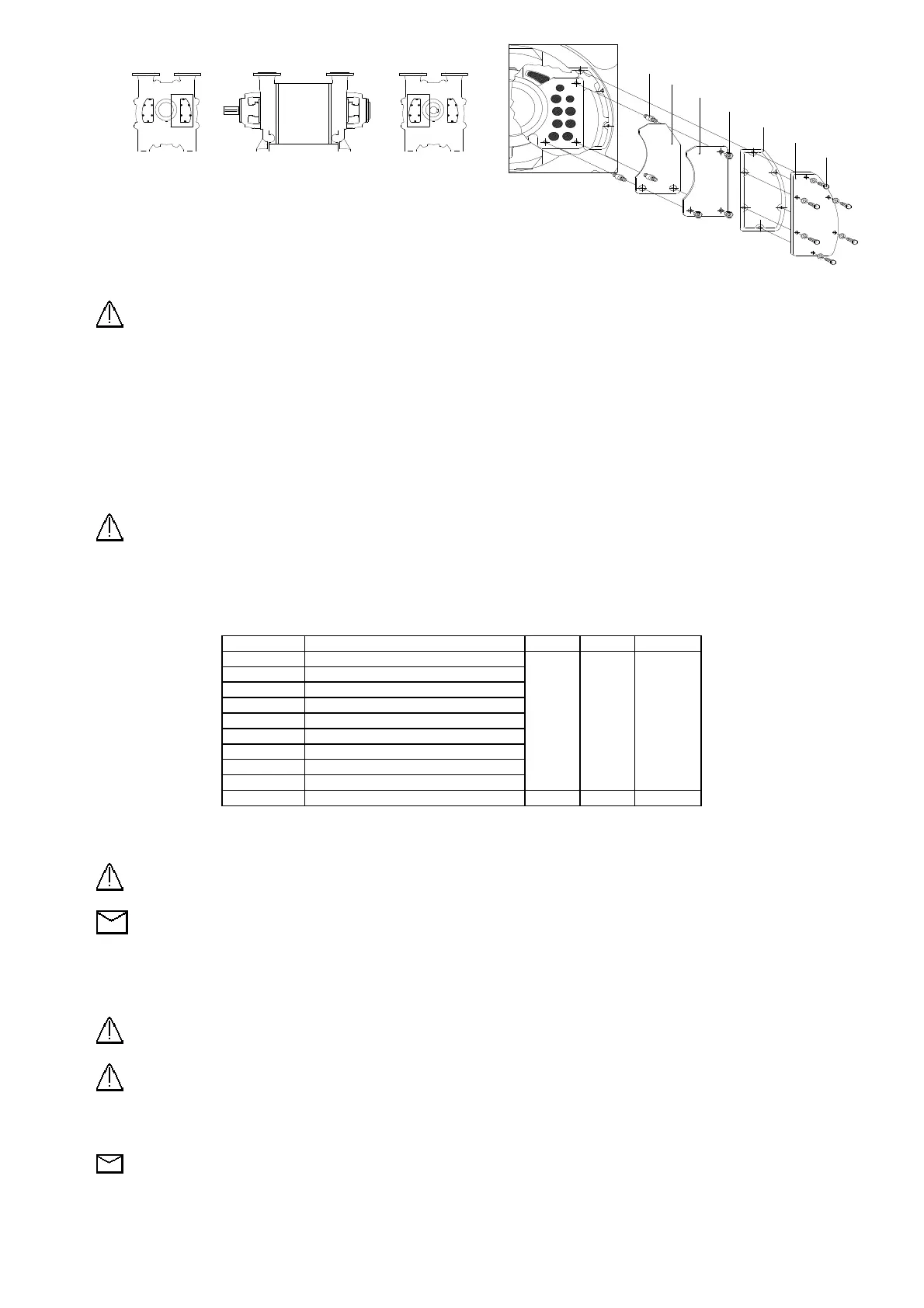

Referring to the sectional drawings, in the table below are indicated the recommended spare parts for normal use according forecast

timing

41 A/P Mechanical seal (set)

60 A/B Automatic discharge valve (set)

31-32 Bearing (set)

15 O-ring (set)

51 O-ring (set) 1 2 4

47 O-ring

21 Shaft sleeve (set)

50 Gasket

44-44A Seal ring (set)

42 Soft packing gland (set) 2 4 8

In case of order please quoting always Type, serial number and year of construction of KRVS (these elements are indicated in front page

of this manual) and relevant position of spare part indicated in the table above.

original spare parts or accessories

Note : ROBUSCHI will not be liable for any damage, breakdown, injury deriving from the use of non

original spare parts or accessories

6.9 Demolition of KRVS

In case of demolition of KRVS verify the eventual presence of explosive, toxic or dangerous substances and dispose them in accordance

with local regulations.

Warning : Transfer KRVS in a safe zone before any operation of demolition

Warning : Dispose the residual of internal liquids in accordance

Demolish the pump in such a way to make impossible to use again the pump as complete unit, or to use again one or several parts of the

pump.

plate of the pump and any other document

62

60

60A

207

50

16

404

Fig.14

Loading...

Loading...