33

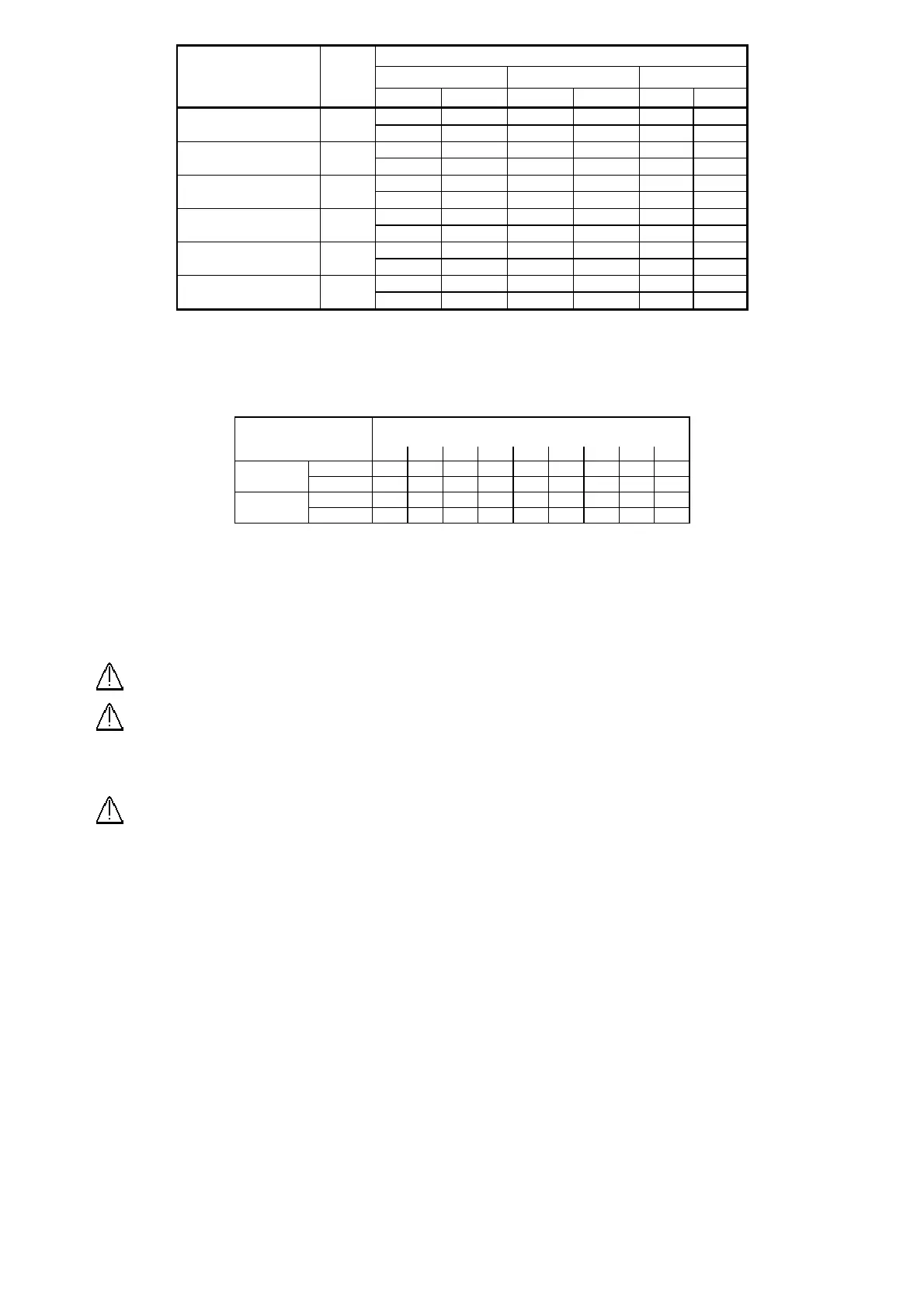

Unit Hz

Suction pressure

33÷200 mbar 200÷600 mbar >600 mbar

5°C 10°C 5°C 10°C 5°C 10°C

KRVS 7-14/P

50 0.30 0.18 0.27 0.17 0.22 0.14

60 0.36 0.22 0.32 0.20 0.27 0.17

KRVS 16-17-21/P

50 0.43 0.27 0.36 0.22 0.32 0.20

60 0.53 0.32 0.43 0.27 0.38 0.23

KRVS 23/P

50 1.00 0.70 1.00 0.70 0.88 0.63

60 1.20 0.84 1.20 0.84 1.05 0.75

KRVS 25/P

50 1.41 0.97 1.37 0.98 1.25 0.89

60 1.70 1.16 1.64 1.17 1.50 1.07

KRVS 30/P

50 2.10 1.32 2.05 1.39 1.78 1.22

60 2.52 1.58 2.46 1.66 2.13 1.46

KRVS 40/P

50 2.85 1.87 2.78 1.97 2.55 1.83

60 3.45 2.24 3.33 2.36 3.06 2.19

Tab.8

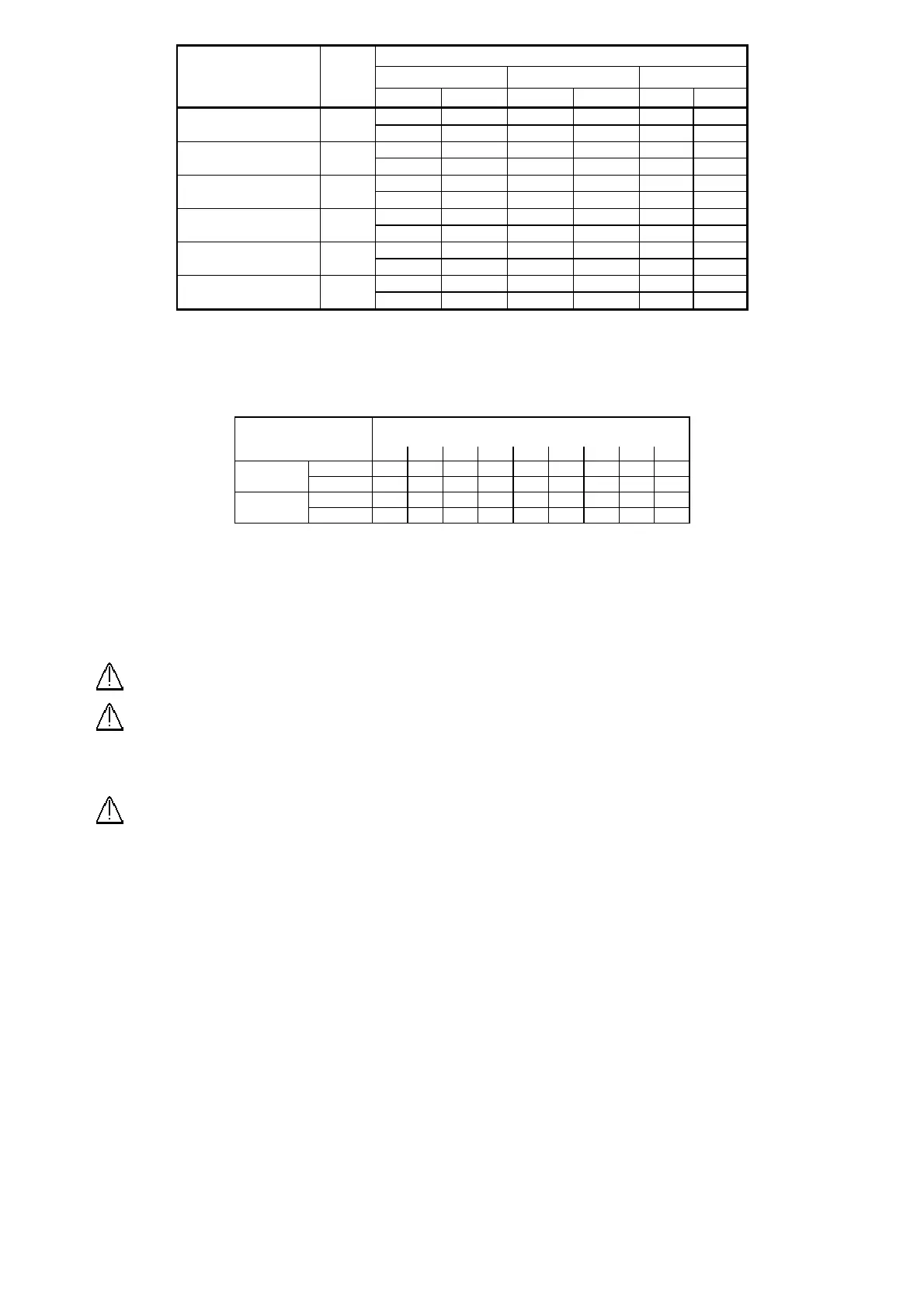

5.3.2 Cooling liquid flow rate

Table 9 shows the cooling liquid flow rate for the total recirculation unit KRVS /T with aspiration of dry air and with aspiration of saturated

air at ambient temperature.

For different operating conditions (vapour aspiration or hot saturated air temperature), please contact ROBUSCHI.

Cooling water flow rate

at 10°C

KRVS

[m

/h] 7 14 16 17 21 23 25 30 40

Dry air 50 Hz 0.45

0.60

0.82

1.13

1.65

2.40

3.60

5.70

7.60

60 Hz 0.60

0.83

1.13

1.65

2.26

3.10

4.76

7.45

10.2

Wet air 50 Hz 0.70

0.93

1.37

1.83

2.64

3.56

5.48

8.46

11.7

60 Hz 0.94

1.26

1.76

2.49

3.41

4.50

7.10

11.0

15.0

Tab.9

5.4 Stopping the unit

To stop the unit:

Disconnect electric power supply.

Close the Vi on/off valve.

Close Vc valve giving the cooling liquid to the heat exchanger (only KRVS /T units).

Warning : Check that the deceleration of KRVS is uniform and without vibrations

Warning : Close the seal cooling liquid supply only when KRVS returns at the ambient

(<40°C)

5.5 Black-out

In case of black out KRVS is not damaged and not induce any risk of explosion.

Warning : During the blackout it is forbidden to carry out any staff service on KRVS

When electrical supply is restored re-start KRVS following plant and start procedures indicated at par 5.2.

Loading...

Loading...