29

4 INSTALLATION

4.1 On-site installation

KRVS has to be installed in a free and clean site. The installing space must grant sufficient

ventilation for the electric motor.

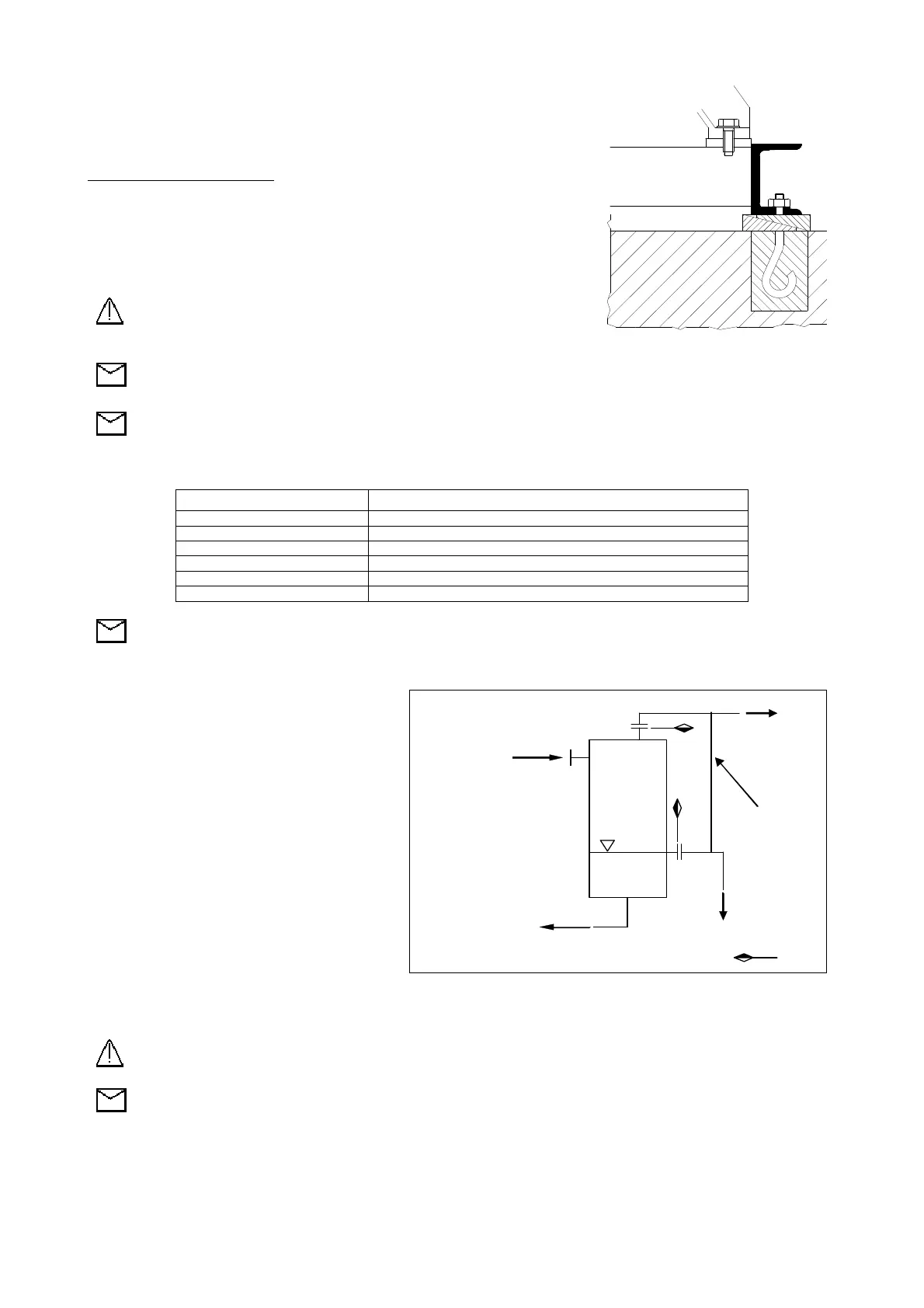

Set KRVS horizontally on an even surface (max 5 mm on 1m) made out of concrete or

with a steel frame. If necessary use dampers between the unit and the floor. Fix KRVS

using four expansion anchor bolts through the relevant holes.

The overall dimensions of the unit are given in technical table

For sizes 23 to 60 put the pump horizontal (max 5 mm on 1m) using shims under the base

and near the foundation bolts (Fig. 6).

Pour the concrete into the holes in the foundation, and after the concrete has hardened (at

least 48 hours) tighten the mounting bolts. Verify that the pump rotates freely by hand. Check

the alignment (see section 4.2.1)

Warning : Ask Robuschi to install KRVS on a metallic structure

Note: Should the pump not be positioned horizontally, please consult us

NOTE for units KRVS 7

21: after installing the unit, check that separator tank is perfectly horizontally

aligned. If required use spacers under the baseplate in order to obtain the horizontal alignment

In case of outdoor installation adopt the following measures

CLIMATIC CONDITIONS MEASURES

Strong sunlight Protect with a canopy

Rainy / Snow Protect with a canopy

Temperature < - 20 °C Use only GRBS-CRBS and heat inside air before any start-up

Wind > 20 m/s Protect with windbreak walls

Hoarfrost Heat inlet silencer

Dust / Sand storm Special filter with preseparator

Note : For different climatic conditions contact ROBUSCHI ( or an authorized distributor )

4.2 Connections

The main connections are those given in the technical

table

To connect main piping, follow with care instructions

below:

Remove flange protections only before connecting

pipes.

Discharge pipe shall discharge to the atmosphere, if not

it has to be protected from overpressure by mean of a

safety valve.

Install a strainer in the suction piping Check that the

diameters of the pipes are not less than the diameters

of the pump flanges.

Clean the piping and remove welding scales, nuts, bolts

and rags.

Check by the arrows on the pump flanges the correct

position of the suction and discharge.

Check that corresponding flanges match perfectly.

Check that gaskets do not protrude into the pipes.

Avoid stress caused by the piping on the pump flanges

due to their weight or thermal distortion.

compressed gas far from people operating in the room where the unit is

installed, connect a suitable pipe to the discharge of separator tank with the same diameter

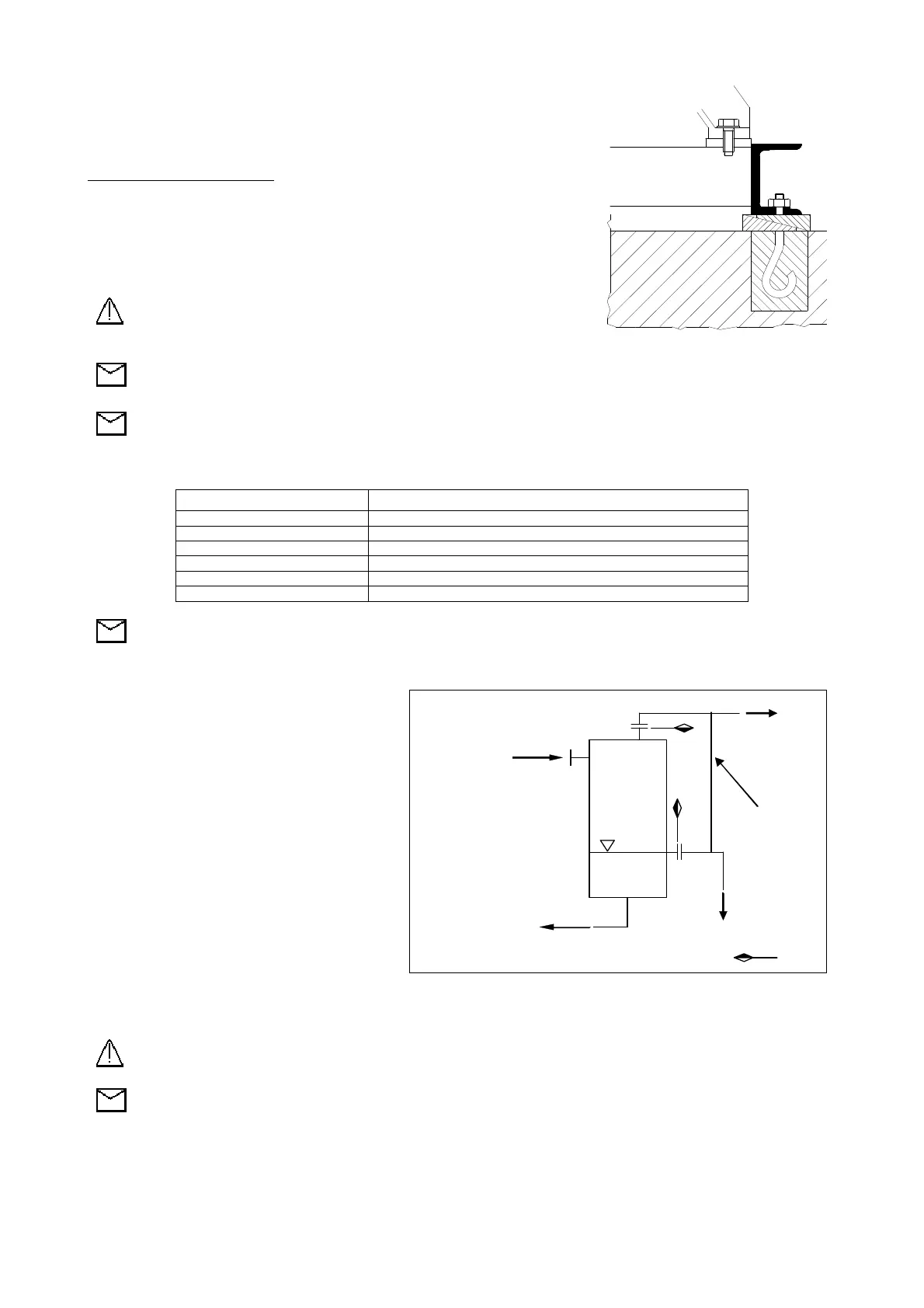

NOTE : The separator tank overflow is designed to discharge the excess of liquid at

pressure directly in a drain funnel. If the overflow is close-connected with a pipe it is necessary to

connect the last with the to the gas discharge pipe by a little tube (see fig. 7) in order to avoid the

siphon priming that in few minutes would empty the tank

4.2 Motor coupling

If the motor is installed by customer the coupling must be done following the instructions indicated in section 6.2.

Fig. 6

To the heat exchanger

or liquid ring pump

From liquid

ring pump

breaker

connection

Supply limit

Fig. 7

Loading...

Loading...