28

3 STORAGE

3.1 Handling

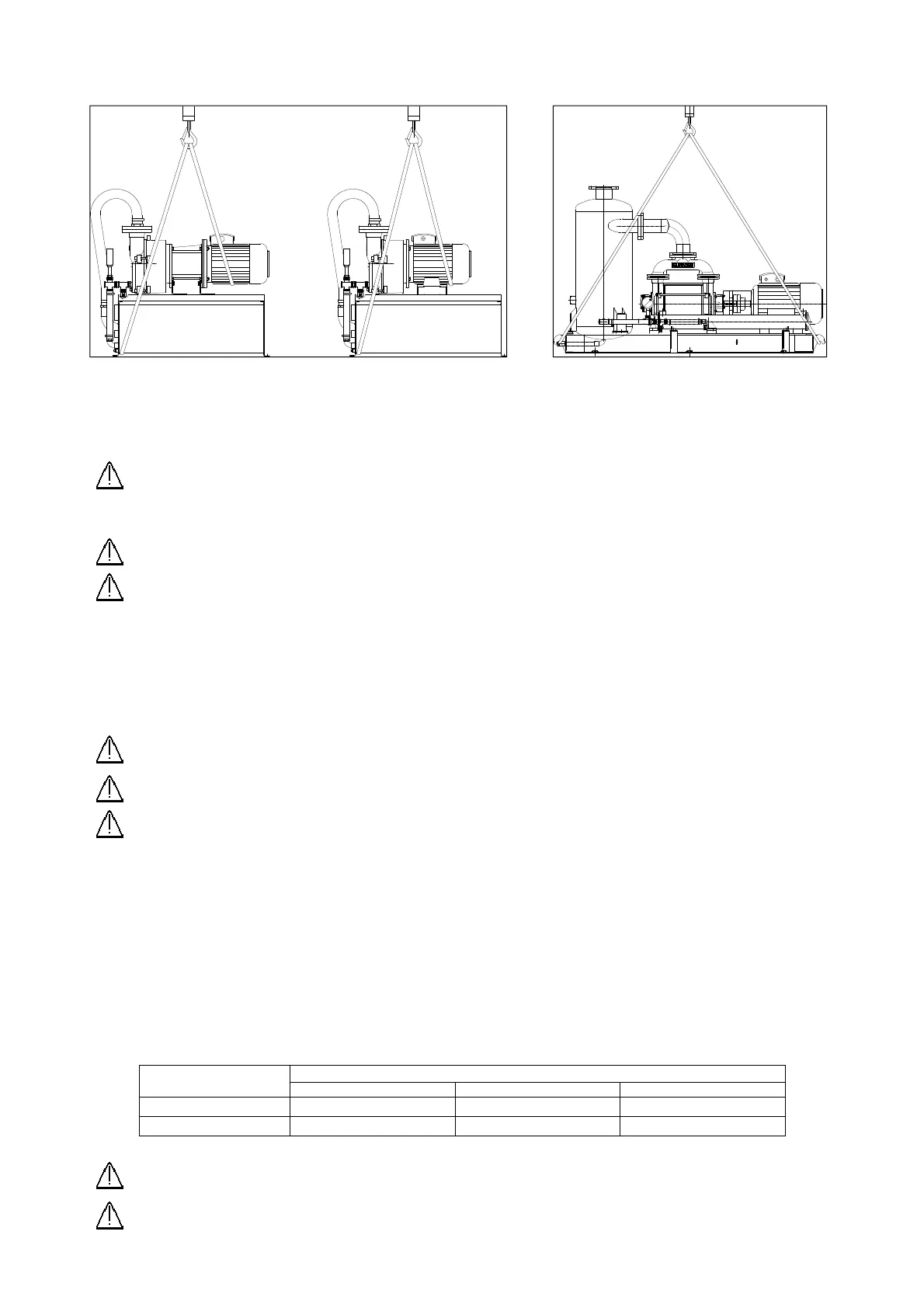

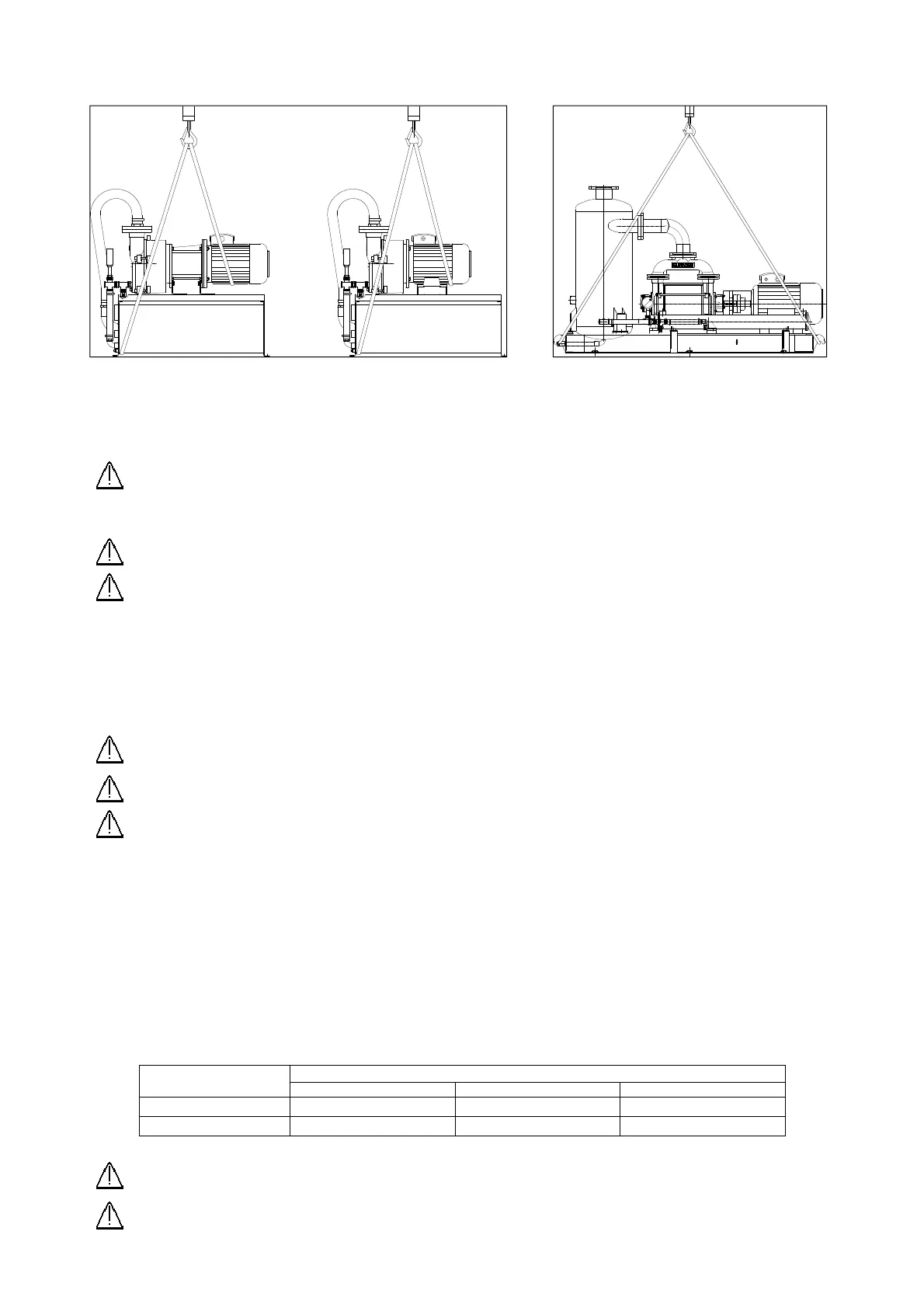

To lift the unit use certified cables as shown in fig. 4-5. Assure that cable span is suitable for the unit weight as given in technical table.

A) bracket version B) close-coupled version

Fig.4 KRVS 7

÷

21 Fig.5 KRVS 23

÷

40

Transport KRVS in a closed transport device protected against the atmospheric agents, in case of sea transport use barrier sac with

hygroscopic salts

During transport fix KRVS to the base of transport devices using belts in order to avoid any possible damage to KRVS

Warning : Remove any free body from the transport device base in order to avoid any possible damage

to KRVS

3.2 Unpacking

Check always the correspondence between documents and materials and the presence of eventual damages due to transport.

Warning : Refer to ROBUSCHI any damage to evaluate the safety conditions of KRVS

Warning : Remove with care the packing only at on

site procedure, dispose all the dangerous elements

(nails, splits, etc…)

3.3 Preservation

Keep KRVS in a closed place protected against atmospheric agents at the following climatic conditions :

Temperature from –20 °C to 40 °C

Relative humidity from 10 % to 80 %

If different climatic conditions are forecast contact ROBUSCHI.

If, during storage, the climatic conditions overcame the indicated limits check KRVS

clearances, the coupling alignment and the screws tightening

Warning : Do not preserve KRVS in atmosphere

with any substance also feebly corrosive

Preserve KRVS onto ground without any weight onto it

Renew the preservation every 6 months or more frequently if humidity is higher than 80% filling-up the inside of the bearing support with

anti-rust oil and spraying it into KRVS.

Keep the unit in a cool, closed and dry environment, preserve the unit from vibrations.

Fill half of the pump with rustproof oil of type given in table II and rotate the shaft for few revolutions to lubricate all the internal parts.

Drain the pump by screwing the drain plugs.

Close all the pump opening.

Protect all the external not painted surfaces by using rustproof oil

Renew the internal preservation every 3 months or more frequently if the climate is particularly damp.

Every month rotate KRVS shaft by hand for a few revolutions

If KRVS has a mechanical seal follow the preservation indication of the seal manufacturer

If the pump ran already and a log inactivity is foreseen:

-Empty the pump from the residual service liquid

-Clean the pump by using a suitable decalcifying solution.

-Provide to store as prevoiusly mentioned

Parts

AGIP ESSO SHELL

Shiny external parts Rustia 27 Rust Ban 397 V-Produkt 9703

Bearings Rustia C 100 Antitrust MZ 110 Ensis Motor Oil 20

Tab.6

rust oil with fire point over 200 °C

Warning : Dispose the used anti

rust oil in accordance with local regulations

Loading...

Loading...