122 Rockwell Automation Publication 750-RM100A-EN-P - August 2019

Chapter 11 Application References

• The experimental method involves displacing of the load to an initial

angle, letting it oscillate for a time period of T seconds while counting the

number of swings n. With this knowledge, frequency is derived as:

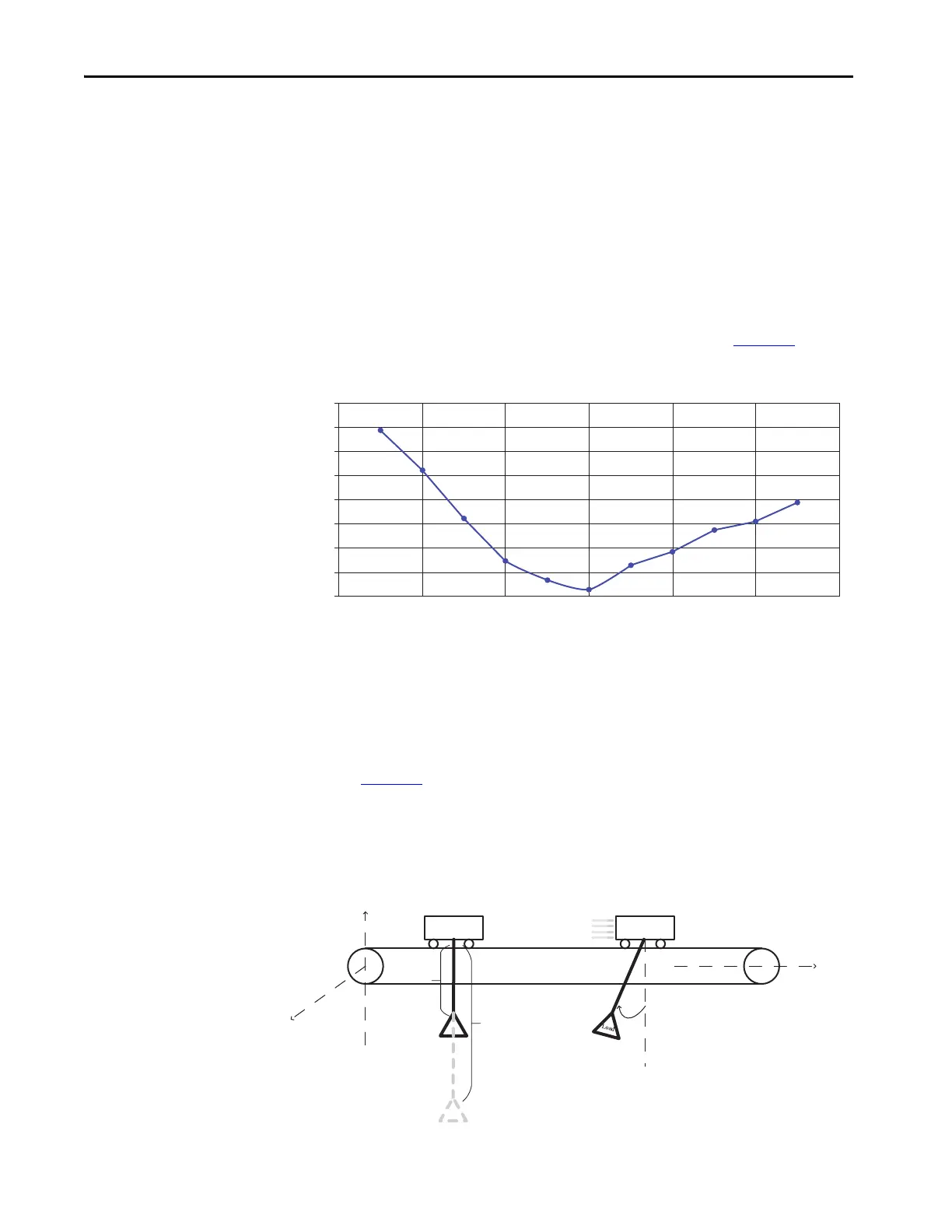

Knowing the accurate cable length is important as it affects the center frequency

of the notch filter. The following experimental result shows how deviation from

the actual cable length affects the sway magnitude when the filter frequency does

not accurately match the sway oscillation frequency. The sway magnitude

increases as the cable length error becomes higher as shown in Figure 45

.

Figure 45 - Sway Magnitude (Degrees) vs. Cable Length Error (Percent)

Cable Length Variation

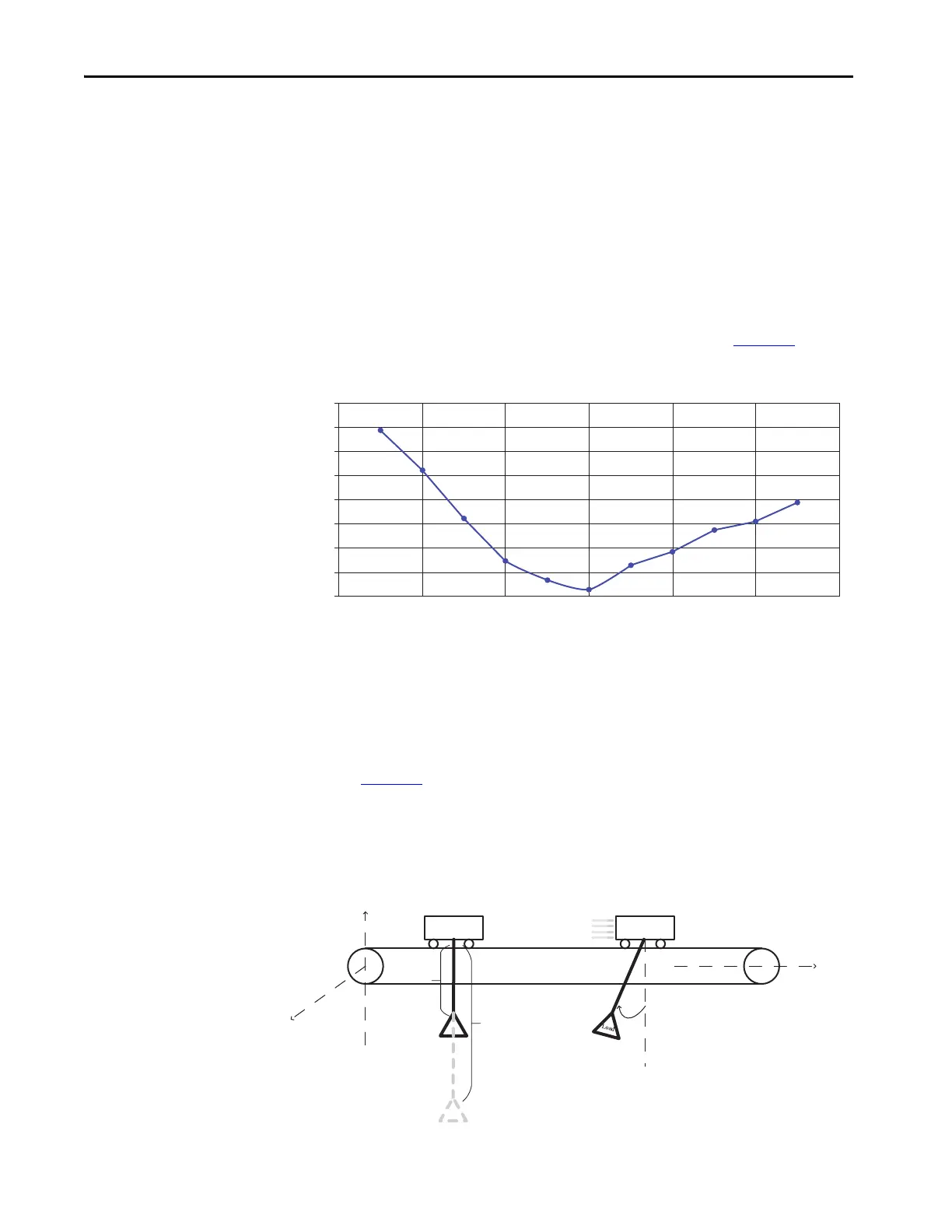

Based on the application, the cable length can vary between a minimum and

maximum length (Lmin and Lmax), which results in a varying sway frequency.

See Figure 46

. The range of such length change can determine the system

configuration.

A larger variation of cable length can result in a larger variation in frequency.

Figure 46 - Simple Diagram for Anti-Sway Application

8

7

6

5

4

3

2

1

0

-60% -40% -20% 0% 20% 40% 60%

Cable Length Implied by Notch Filter / True Cable Length

Sway Magnitude (Degrees)

Trolley

Z- axis Hoist

L

min

Load

L

max

Sway magnitude

(degrees)

Y- axis

Gantry

Load

Loading...

Loading...