Maintenance

Repair

MagneMover LITE Service Manual 121

Rockwell Automation Publication MMI-UM037A-EN-P - April 2020

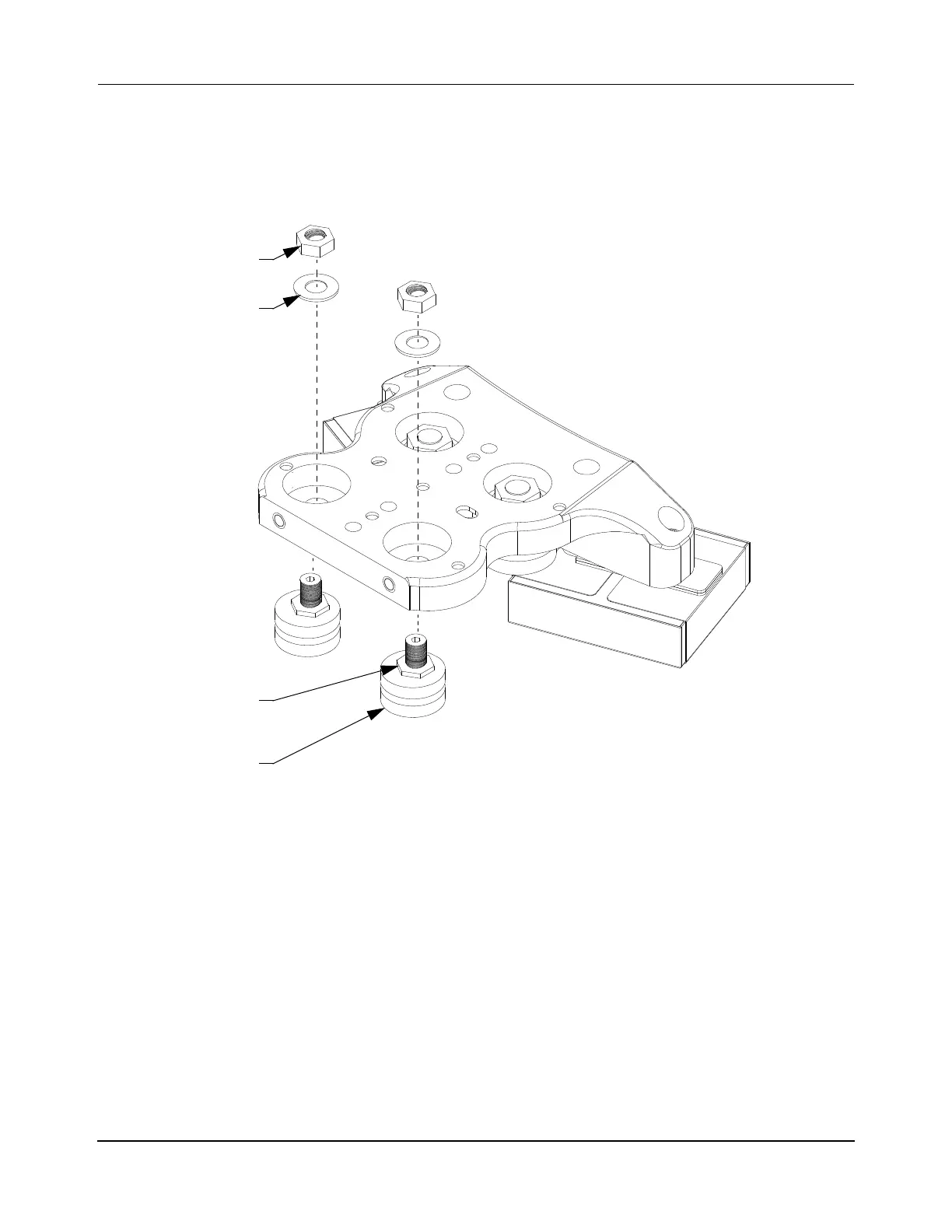

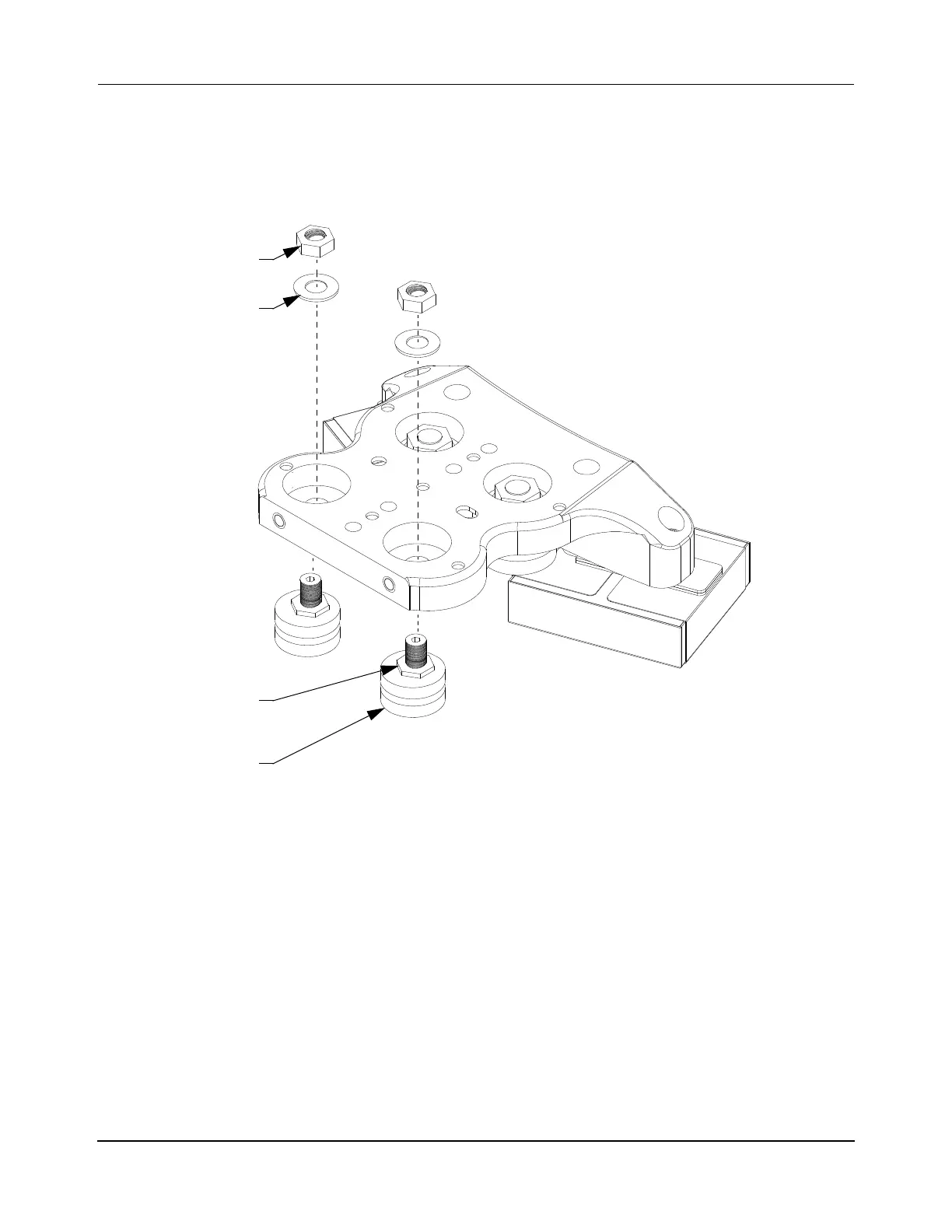

Replace Eccentric Bearings

If concentric bearings are to be replaced on this vehicle, perform that procedure first (see

Replace Concentric Bearings). Figure 48 shows a dual array vehicle, however the same pro-

cess is used for single array vehicles.

Figure 48: Precision Rail Vehicle Eccentric Bearings Disassembly/Assembly

1. Stop all motion on the path where the vehicle is located.

2. Remove the vehicle from the precision rail (see Replace Precision Rail Vehicles on

page 104).

3. Place the vehicle on a non-metallic work surface with the magnet array down. Keep

the magnet array at least three feet away from metal objects and tools.

4. Hold the bearing nut underneath the carriage in place with a 13 mm thin open ended

wrench. Unscrew and remove the nut and washer for the eccentric bearing being

removed (on the top of the carriage) and store them for reuse.

5. Remove the eccentric bearing from the bottom of carriage and discard appropriately.

Eccentric

Washer

Bearing

Bearing Nut

(2X)

Top Nut

(2X)

(2X)

(2X)

Loading...

Loading...