EN

65

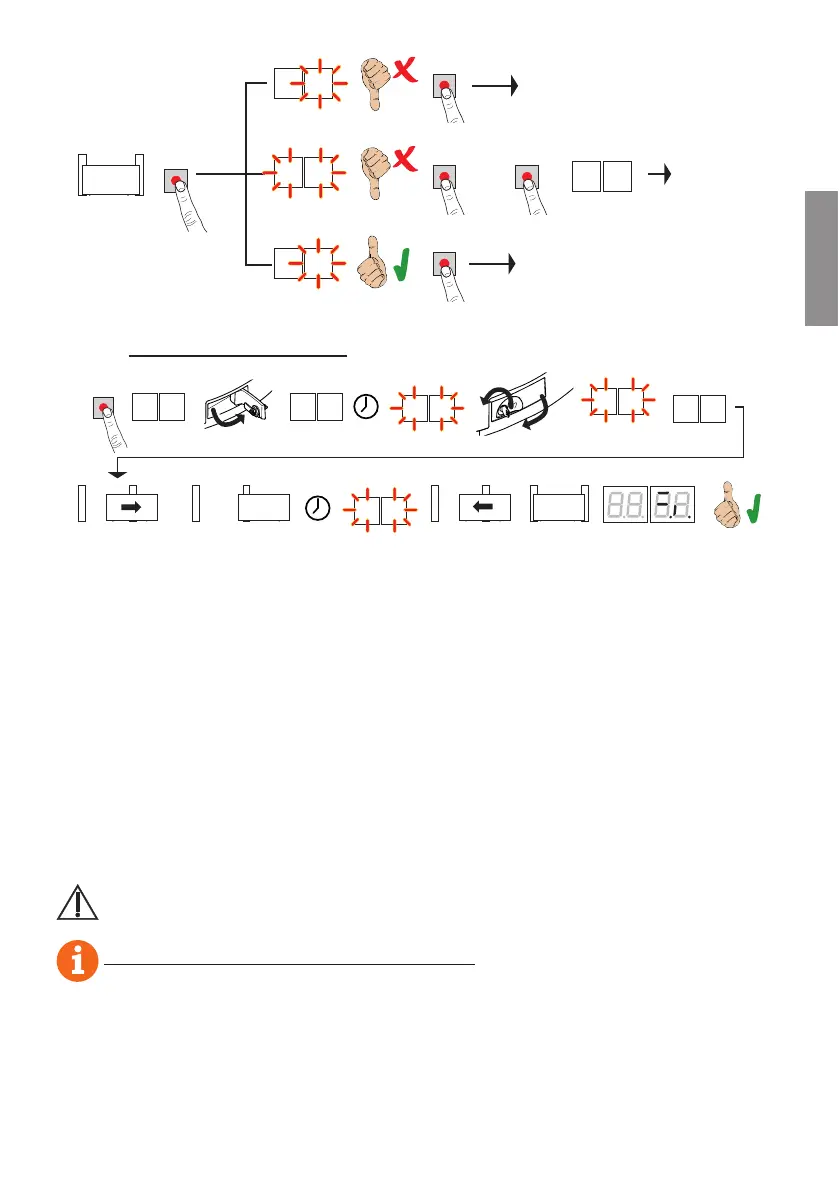

CLOSE

TEST

SEE CHAPTER 16 and 17

ACQUISITION

PROCEDURE

CHAP. 11.2

ACQUISITION

PROCEDURE

CHAP. 11.2

fC

17

YES

No

ta

da

No

Press and hold on

TEST

TEST

TEST

PROG

AP P-

Until ...

1 click

1 click

1 click

1 click

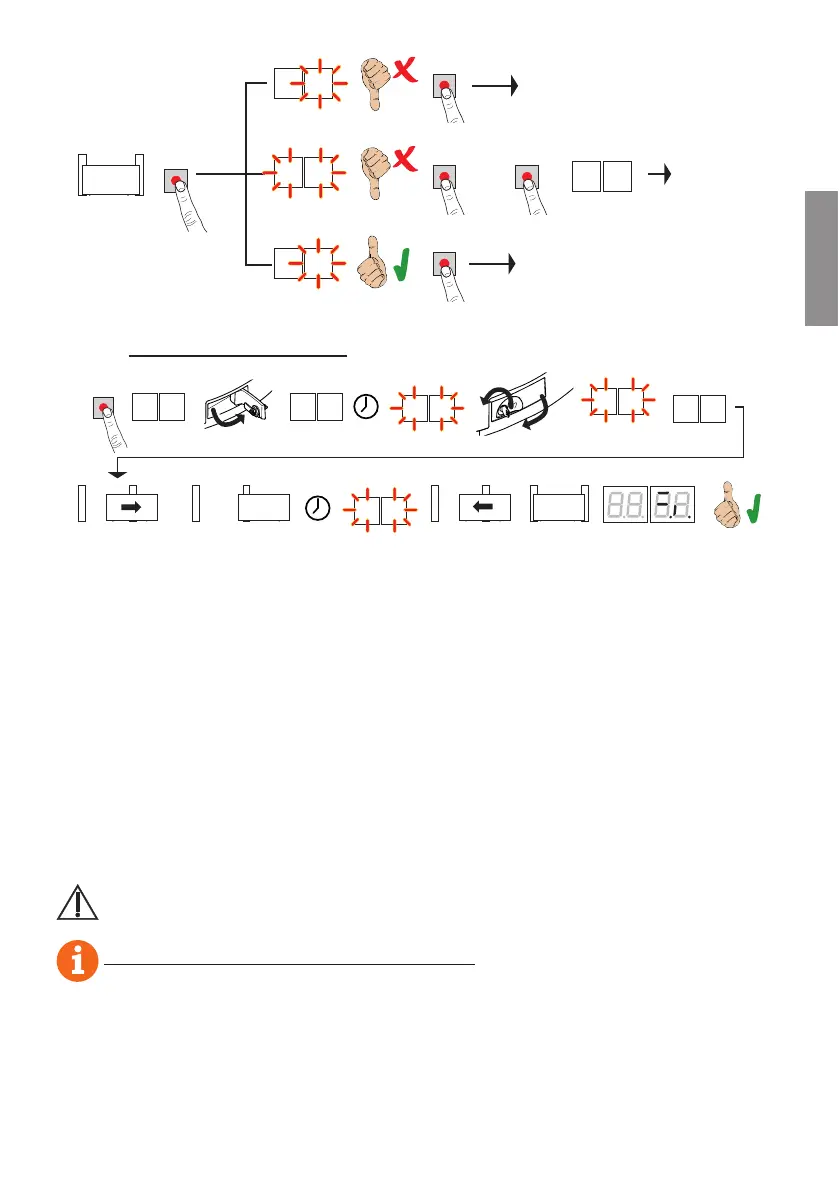

11.2 Acquisition procedure:

PROG

AP P- PH A5

AU to

x4 s

Wait ...

OPENING OPEN CLOSING

(if FT are connected

or enabled)

CLOSE

Yes

AU

to

PH

A5

FO

TO

• Press and hold PROG for 4 seconds. $3 3 is shown on the display.

• Open the release handle. The message 3+ $6 appears on the display after a few seconds. The controller unit

launches a calibration procedure. The operating parameters of the motor are determined during calibration.

• If the motor calibration procedure is successful, the message 3+ $ܫFXMJXTSYMJINXUQF^

• Close the release handle. The acquisition procedure now starts.

• )2W2is shown on the display (only if parameters , , , are not disabled). Keep away from the photocell

beam within 5 s, to prevent interrupting the procedure.

• $XWR is shown on the display and the gate starts opening at low speed.

• 9MJLFYJXYTUXGWNJܫ^\MJSNYWJFHMJXYMJLFYJTUJSQNRNYX\NYHM$XWRܫFXMJXTSYMJINXUQF^

• The gate closes until it reaches the gate closed limit switch.

If the acquisition procedure is completed successfully, the display enters the command and safety device state display

mode.

If the following error messages are shown on the display, repeat the acquisition procedure:

• QR3+: calibration procedure failed.

• $33(: acquisition error. Press the TEST button to clear the error, and check the safety device in alarm state.

• $33/: travel length error. Press the TEST button to clear the error, and check that gate is completely closed.

ATTENTION: if the acquisition procedure was successful BUT the space between the leaf (stopped at the limit

switch) and the mechanical stop is not as desired, move the limit switch and REPEAT THE ACQUISITION

PROCEDURE. Ensure that AT LEAST 3 centimetres remain between the leaf stop and the mechanical stop.

For more information, see chapter 17 “Alarms and faults”.

Loading...

Loading...