Reference Manual

00809-0100-4809, Rev DA

Appendix B: Product Certifications

September 2015

214

Product Certifications

IE FM FISCO

Certificate: 3031960

Standards: FM Class 3600 - 2011, FM Class 3610 - 2010,

FM Class 3611 - 2004, FM Class 3616 - 2006,

FM Class 3810 - 2005, NEMA 250 - 1991

Markings: IS CL I, DIV 1, GP A, B, C, D;

T4(-50 °C

T

a

+70 °C); when connected

per Rosemount drawing 03151-1006; Type

4X

Canada

E6 CSA Explosionproof, Dust-Ignitionproof, and Division 2

Certificate: 1143113

Standards: CAN/CSA C22.2 No. 0-10,

CSA Std C22.2 No. 25-1966,

CSA Std C22.2 No. 30-M1986,

CAN/CSA C22.2 No. 94-M91,

CSA Std C22.2 No. 142-M1987,

CSA Std C22.2 No. 213-M1987,

ANSI/ISA 12.27.01-2003,

CSA Std C22.2 No. 60529:05

Markings: Explosionproof Class I, Division 1, Groups B,

C, D; Dust-Ignitionproof Class II, Division 1,

Groups E, F, G; Class III; suitable for Class I,

Division 2, Groups A, B, C, D; Type 4X

I6 CSA Intrinsically Safe

Certificate: 1143113

Standards: CAN/CSA C22.2 No. 0-10,

CSA Std C22.2 No. 30-M1986,

CAN/CSA C22.2 No. 94-M91,

CSA Std C22.2 No. 142-M1987,

CSA Std C22.2 No. 157-92,

ANSI/ISA 12.27.01-2003,

CSA Std C22.2 No. 60529:05

Markings: Intrinsically Safe Class I, Division 1; Groups A,

B, C, D; suitable for Class 1, Zone 0, IIC, T3C;

when connected per Rosemount drawing

03151-1207; Type 4X

IF CSA FISCO

Certificate: 1143113

Standards: CAN/CSA C22.2 No. 0-10,

CSA Std C22.2 No. 30-M1986,

CAN/CSA C22.2 No. 94-M91,

CSA Std C22.2 No. 142-M1987,

CSA Std C22.2 No. 157-92,

ANSI/ISA 12.27.01-2003,

CSA Std C22.2 No. 60529:05

Markings: FISCO Intrinsically Safe Class I, Division 1;

Groups A, B, C, D; suitable for Class I, Zone 0;

T3C; when installed per Rosemount drawing

03151-1207; Type 4X

Europe

E1 ATEX Flameproof

Certificate: KEMA 00ATEX2143X

Standards: EN 60079-0:2012, EN 60079-1: 2007,

EN 60079-26:2007 (3051SFx models with

RTD are certified to EN 60079-0:2006)

Markings: II 1/2 G Ex d IIC T6…T4 Ga/Gb,

T6(-60 °C

T

a

+70 °C),

T5/T4(-60 °C

T

a

+80 °C)

Special Conditions for Safe Use (X):

1. The device contains a thin wall diaphragm. Installation,

maintenance and use shall take into account the

environmental conditions to which the diaphragm will

be subjected. The manufacturer's instructions for

installation and maintenance shall be followed in detail

to assure safety during its expected lifetime.

2. For information on the dimensions of the flameproof

joints the manufacturer shall be contacted.

I1 ATEX Intrinsic Safety

Certificate: Baseefa08ATEX0064X

Standards: EN 60079-0: 2012, EN 60079-11: 2012

Markings: II 1 G Ex ia IIC T4 Ga,

T4(-60 °C

T

a

+70 °C)

Special Conditions for Safe Use (X):

1. If the equipment is fitted with the optional 90 V

transient suppressor, it is incapable of withstanding the

500 V isolation from earth test and this must be taken

into account during installation.

2. The enclosure may be made of aluminum alloy and

given a protective polyurethane paint finish; however,

care should be taken to protect it from impact or

abrasion if located in a Zone 0 environment.

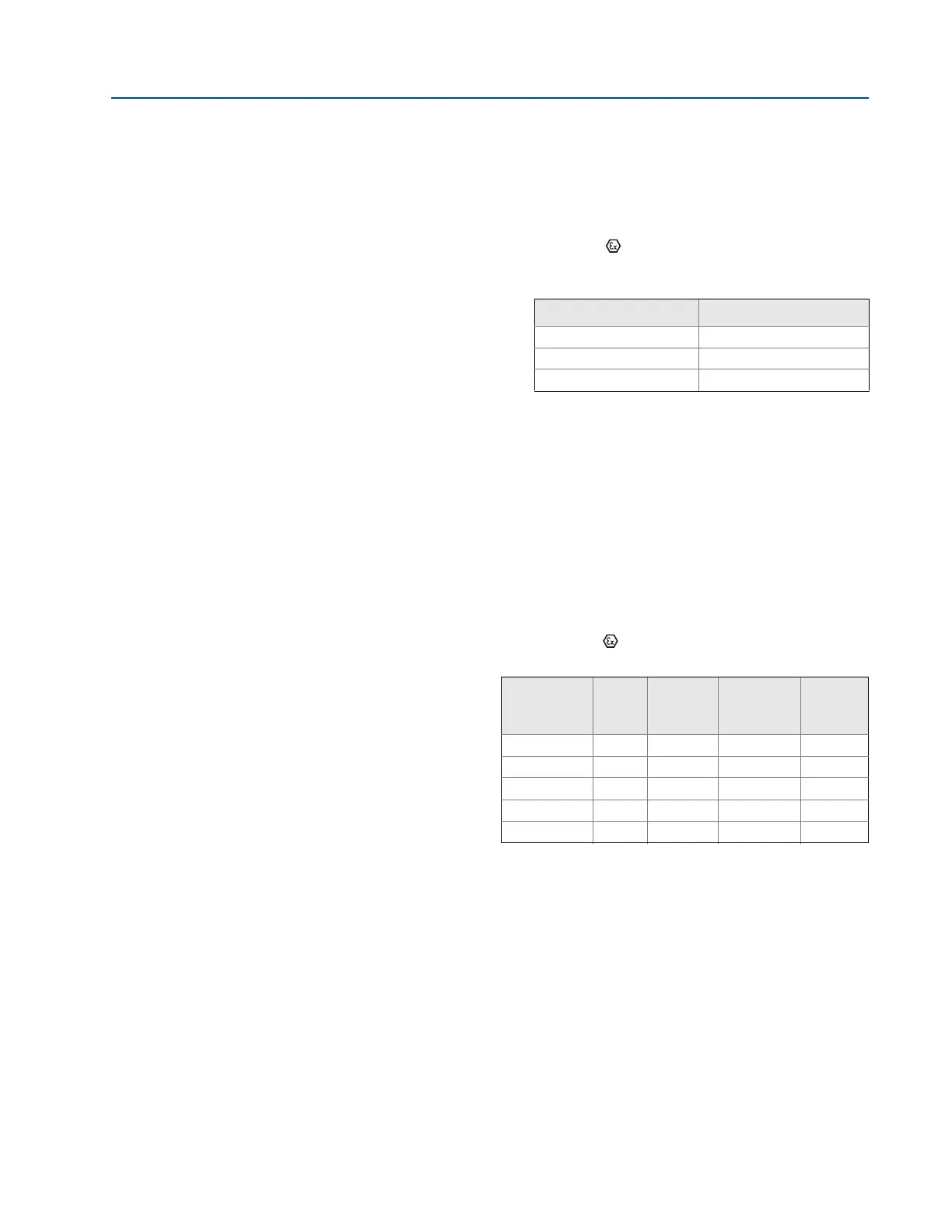

Temperature class Process temperature

T6 -60 °C to +70 °C

T5 -60 °C to +80 °C

T4 -60 °C to +120 °C

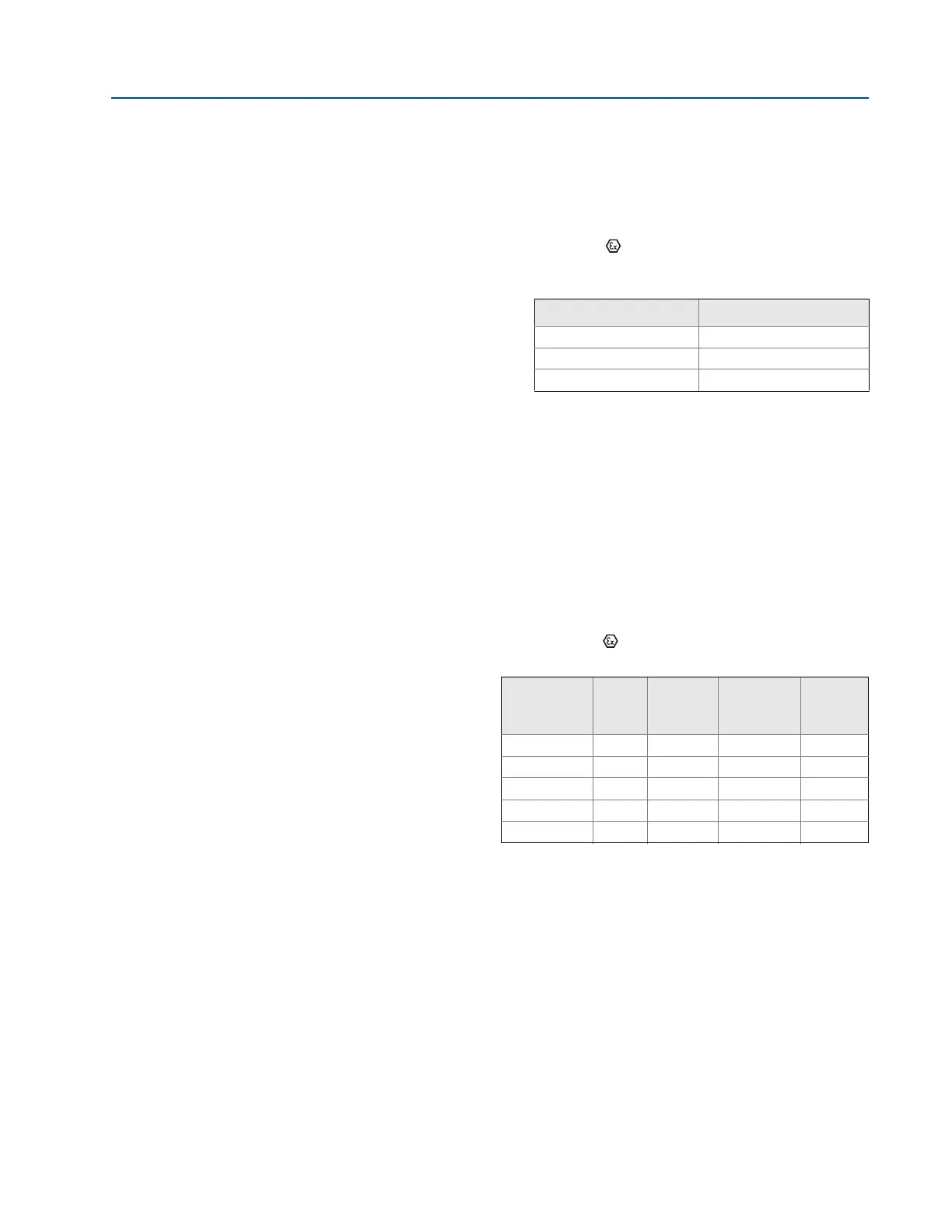

Parameters

HART

FOUNDATION

Fieldbus

SuperModule

only

RTD

(for

3051SFx)

Voltage U

i

30 V 30 V 7.14 V 30 V

Current I

i

300 mA 300 mA 300 mA 2.31 mA

Power P

i

1 W 1.3 W 887 mW 17.32 mW

Capacitance C

i

14.8 nF 0 0.11 uF 0

Inductance L

i

0 0 0 0

Loading...

Loading...