38

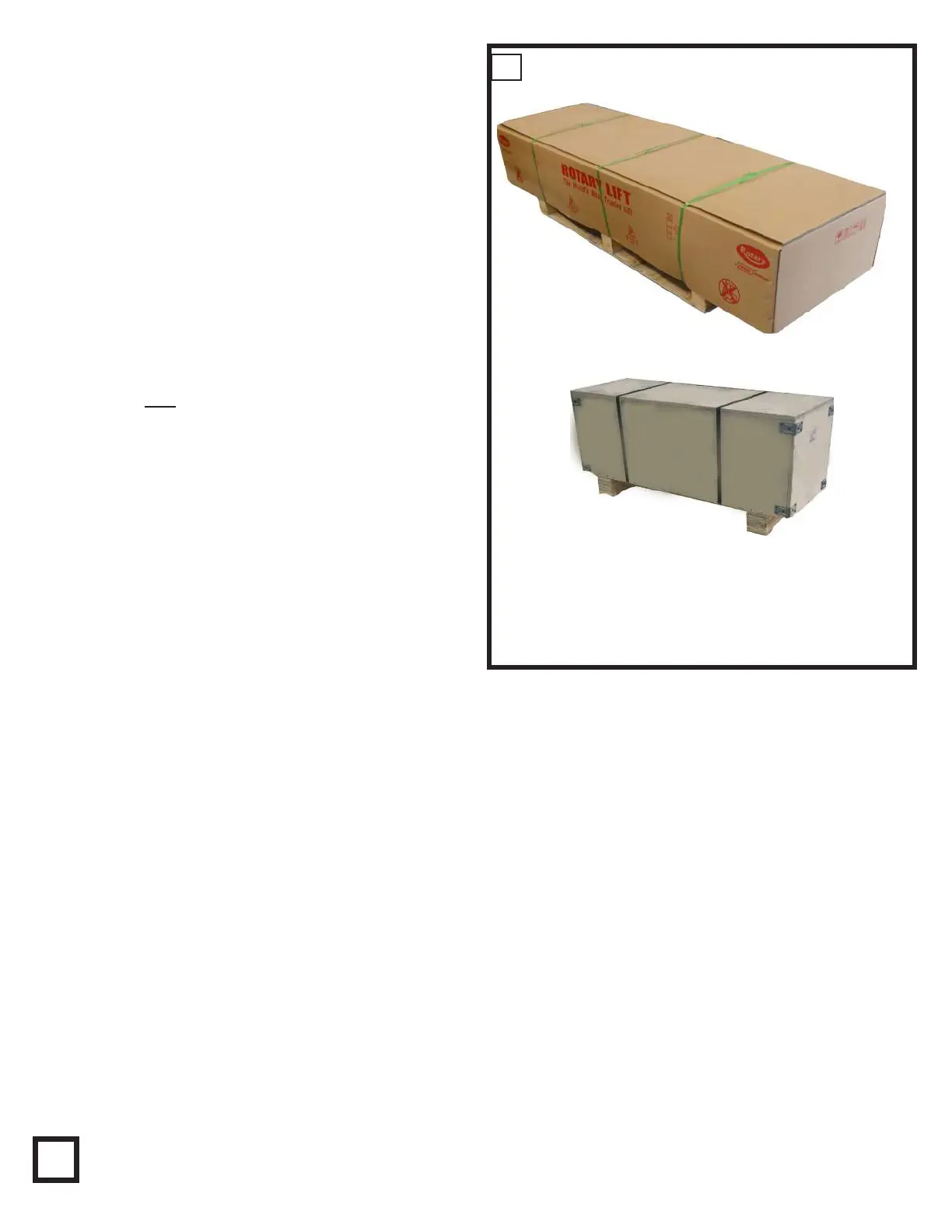

10.1 Transport

The lift is supplied in a packing unit (base unit)

plus a separate control cabinet . The packing

unit comes with the following documentation:

• Transport description giving suitable suspension

points, total weight, centre of gravity, required

cable lengths, transport locks, etc.

• List of all individual components included in

delivery.

10.2 Ofoading

1. Inspect the shipment for any shipping or transport

damage. Immediately report any damage to your

supervisor and to the transport rm.

2. Transport the packing unit to the installation site.

This must conform to the approved environmental

conditions ( → Chapter 7. Technical data).

3. Unfasten the transport locks for the large parts on

the front of the packing unit.

4. Ofoad the base lift and control cabniet and set

down carefully.

5. Remove all other components from the pallet

and set down carefully.

6. Inspect the supplied parts according to the

packing list provided.

7. Dispose of packaging in an environmentally

friendly manner, in compliance with the

regulations applicable in your country

( → Chapter 16. Disposal).

10.3 Storage

Lift components must always be stored in a dry

place (no corrosion protection).

Recommended Storage Conditions

•

Ambient temperature: -5 ... +50

•

Relative humidity, 30 % ... 95 %

with condensation, at 20 °C

The manufacturer provides no warranty for

corrosion damage caused by incorrect

storage.

16

Base lift package

Control cabinet with power unit package

*The packing is slightly different in different market.

Loading...

Loading...