14.3)

Cooling system:

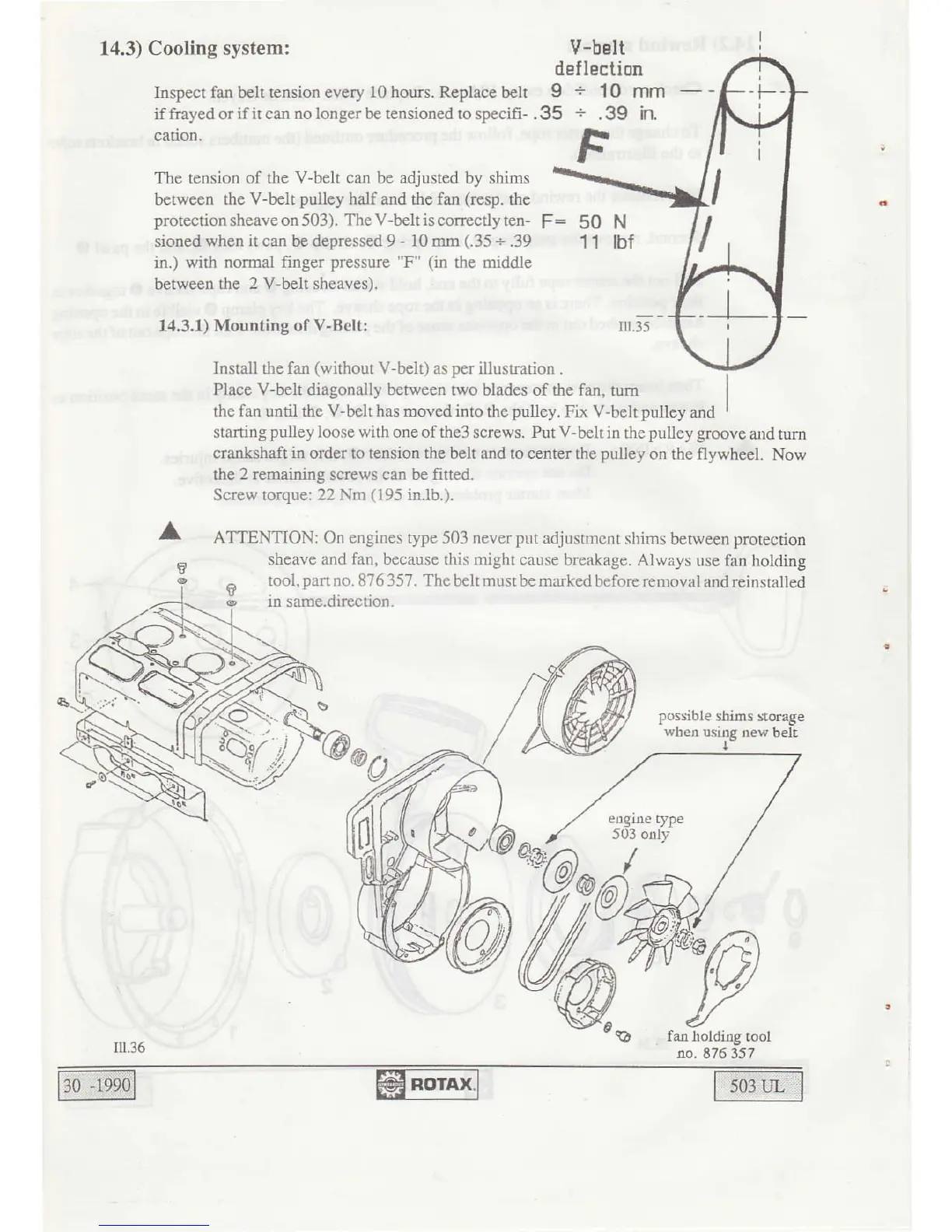

V-bElt

deflection

I

+

10 mm

--

Inspect fan belt tension every 10 hours. Replace belt

iffidyed or

if it can no longe! be tensioled to

specifi-

cation.

.35

+

.39 in.

The tension of the V-belt can be

adusted

by shims

between the V-belt

pulley

half

and the

fan

(resp.

the

protection

sheave on 503).

The v-belt is

co(ectly ten-

F=

sioned

when it can b€ depress€d 9

-

10 mm

(.35 +

.39

in.) wirh nomal

finger

prcssure "F" (in

the middle

between

the 2 V-belt sheaves).

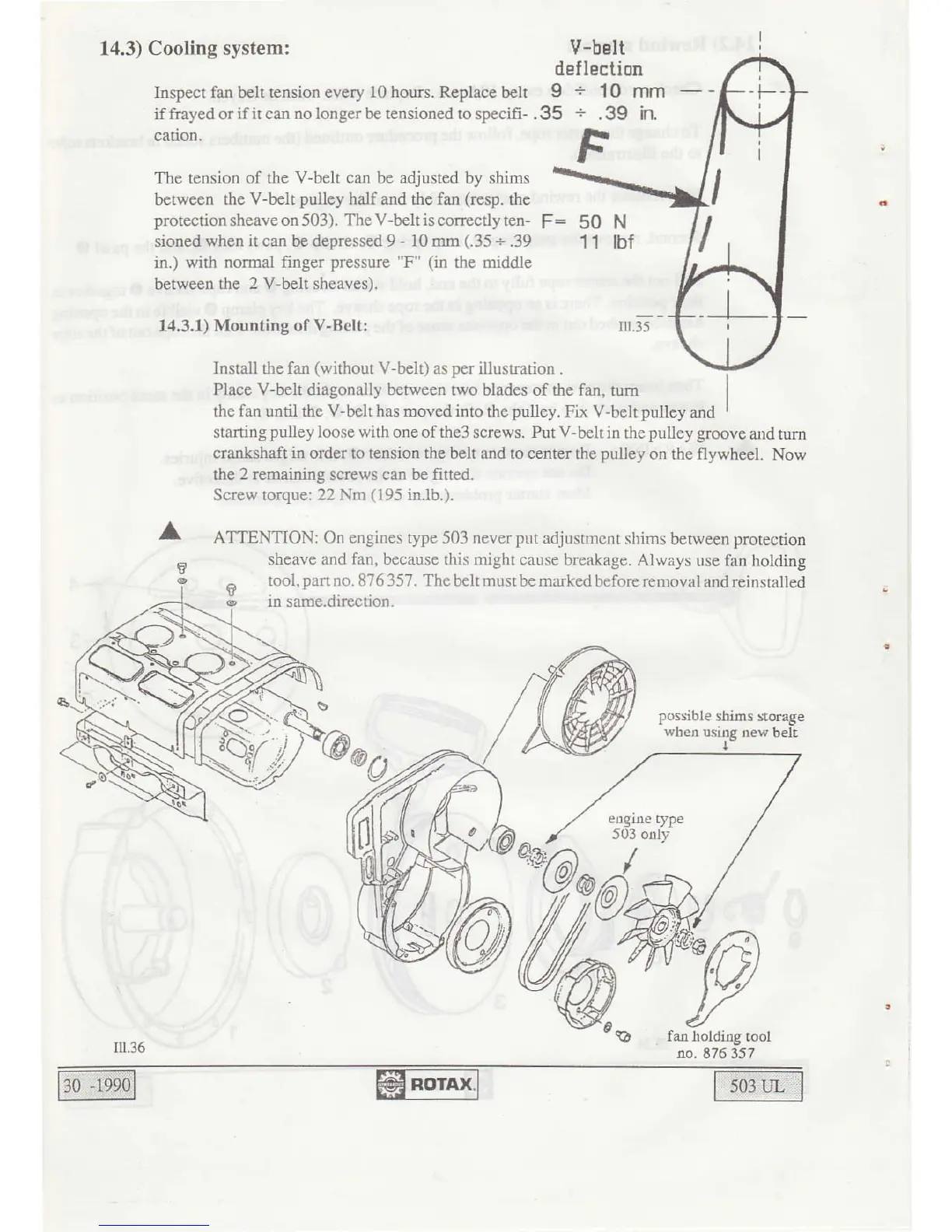

14.3.1) Mounting of

V-Beltr

Ilt.35

Install the fan

(without

V-belt)

as

per

illustration .

Placc V-belt

diagonally

between

two blades of the fan,

tum

the

fan until the V-belt has moved into

the

pulley.

Fix V-belt

pulley

and

starting

pulley

loose with one of the3

screws.

Put V-belr

in the

pulley grcove

and tur:n

cnnkshaft irr order to tension the belt and to center

the

pulley

on the flywheel.

Now

the 2 remaining

screws

can be htted.

Sclew

torque: 22 Nm

(195

in.lb.).

ATTENTION:

On engines

type

503 never

put

adjustmcnt

shims between

protection

sheave aad

fan,

because this might cause

brreakage. Always

use fan holding

c

tool,

pan

no. 876 357. The belt musr be marked

before removal

and reinstalled

; in

same.direction.

possible

shims storage

\,vbcn

$ing new belt

edg e Etpe

503 only

far loldilg

tool

50N

11 tbf

^'

Loading...

Loading...