5.Reference of Welding Standard(DVS2207-1-1995)

5.1 Because of difference in welding standard and PE material, the time and pressure vary in

different phases of welding. It suggests that the actual welding parameters should be offered

by pipes and fittings’ manufacturers.

5.2 Reference standard DVS2207-1-1995

(Bead build-up pressure )Welding pressure =(P1)P3+Drag pressure

Section of welding pipe ends

welding pressure = × 0.15 + Drag pressure(MPa)

Total section of cylinders

Note:The drag pressure is not more than 50% of the welding pressure.

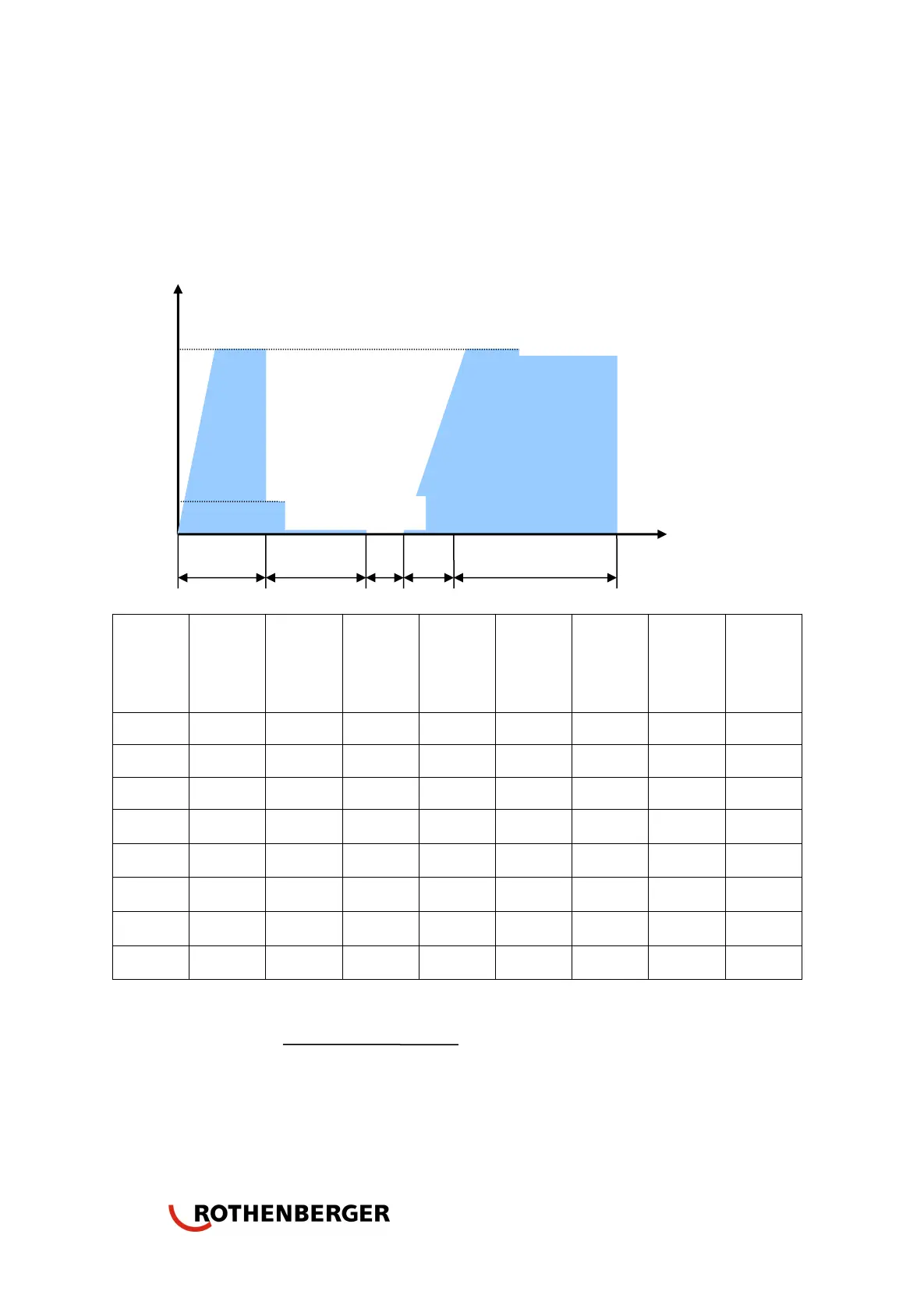

Bead

build-up

pressure

(

MPa

)

Pressure

build -up

time

t

4

(

sec

)

Section of welding pipe ends =

3.14 ×(Pipe diameter - Wall thickness)× Wall thickness

Loading...

Loading...