Section 3 Safety 3-4 S85A / S86A Manual

www.rottlermfg.com

This machine operates under computerized control and, as with all

computerized equipment, is susceptible to extraneous electrical impulses

internally for externally produced. The machine may make moves out of the operator control at any time.

The operator should work in and around the machine with caution at all times.

The operator and nearby personnel should be familiar with the location and operation of the Emergency

Stop Button.

Make sure all electrical equipment has the proper overload protection. This machine should have a fully

isolated power supply to prevent damage and uncontrolled movement of the machine. If this machine is

on the same power lines that are running to other electrical equipment (grinders, welders, and other AC

motors) electrical noise can be induced into this machines electrical system. Electrical noise can cause

the controller to see false signals to move. Not supplying a fully isolated supply to the machine may void

factory warranty. Refer to the Power supply section located in the Installation section for voltage and

amperage requirements of this machine.

Machine Operator

The operator of this machine should be a skilled machinist craftsman who is well versed in the caution,

care, and knowledge required to safely operate metal cutting tools.

If the operator is not a skilled machinist he/she must pay strict attention to the Operating Instructions

outlined in this manual, and get instruction from a qualified machinist in both production and operation of

this machine.

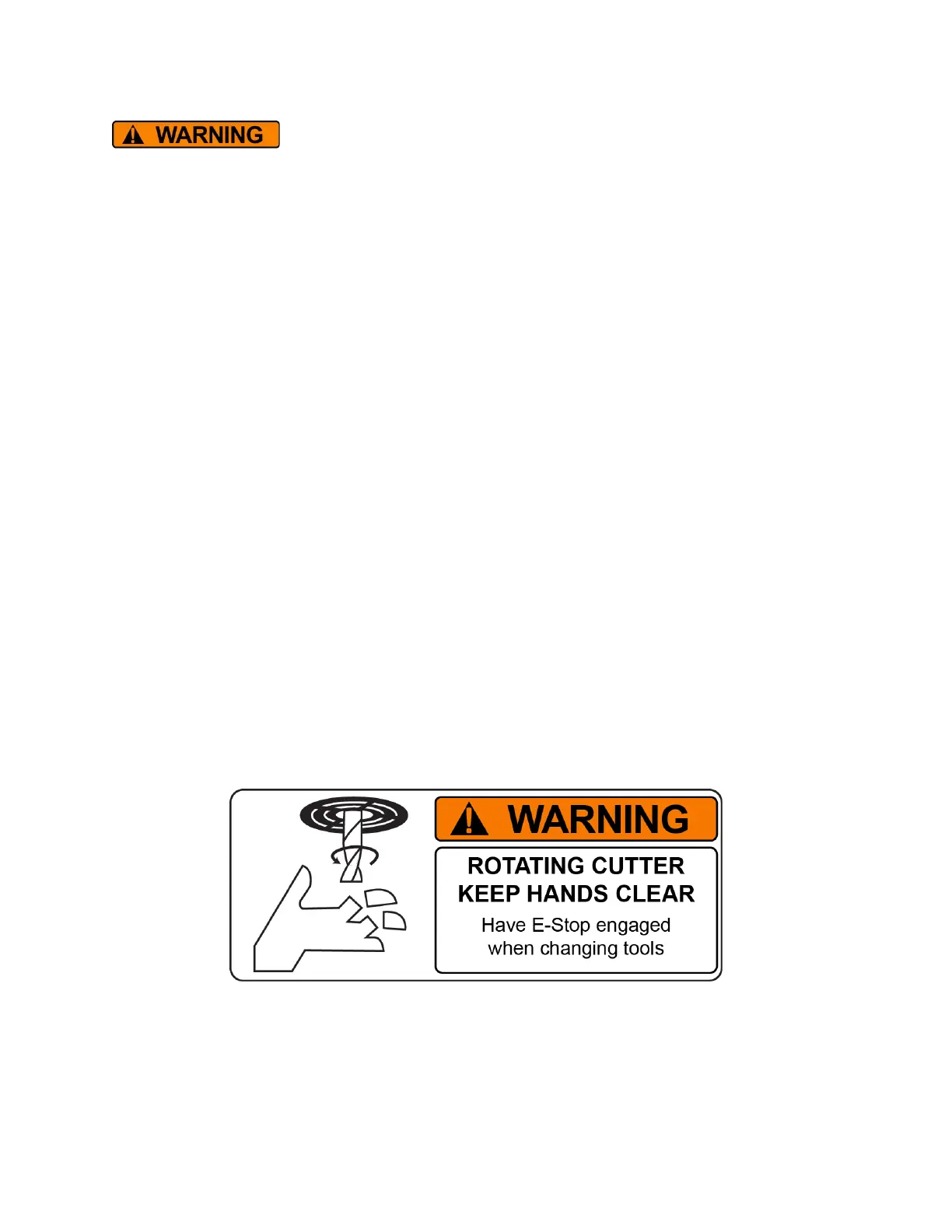

This machine has the following areas of exposed moving parts that you must train yourself to respect and

stay away from when they are in motion

Cutting Tool Area – Any operation involving hands in the cutter head area, such as inspection or

alignment of the cutter head or tools, changing Centering Fingers, tool insertion, and removal, cutter head

changes, and size checking etc. requires the machine to be in Neutral.

Machining – Eye protection must be worn during all operations of the machine. Hands must be kept

completely away from the cutter head. All chip guards must be in position during machine operations.

Loading...

Loading...