Section 3 Safety 3-12 S85A / S86A Manual

www.rottlermfg.com

Cutting Inserts

Standard Inserts and Usage

Rottler offers several different 3/8” and 1/2” IC negative rake inserts for the SF machine. Below is a

description of each.

6303B

A round 3/8” IC, double sided, CBN Insert. An excellent, long life insert for surfacing cast iron heads and

blocks -round shape gives many cutting edges on each side of insert. When using a 14” cutterhead (SF,

F65, F80) speeds range from 900-1200 RPM. When using an 18” cutterhead (F80) speeds range from

600-800 RPM.

6303M

A round 3/8” IC, single sided, PCD Insert. For use on aluminum only - heads and blocks without liners.

This insert has a thin layer of PCD applied to a carbide disk. The diamond appears to be a shiny black

wafer. The hardness of the diamond resists the abrasive nature of the silica in aluminum heads and

blocks. RPM speeds with a 14” cutter range from 900-2000 RPM.

6303K

A round, 3/8” IC, single sided, coated carbide Insert. This is a very economical, general purpose insert

for surfacing aluminum. It is advisable to use this insert for rough cutting to remove welding or

contaminants before. A PCD insert should be used for the final cut to give the super fine finish required

for MLS (multi layer steel) head gaskets. RPM speeds with a 14” cutterhead range from 600-1000 RPM.

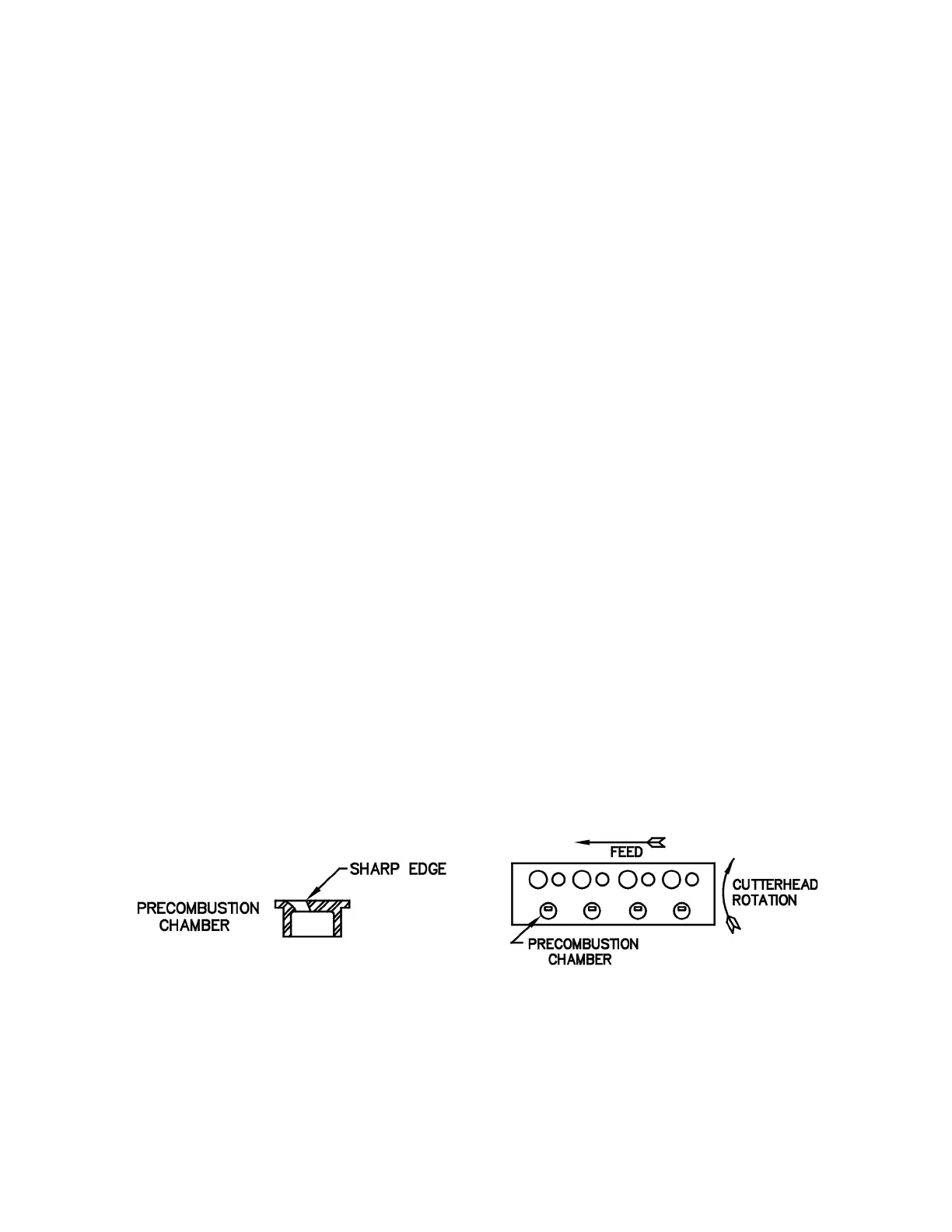

6303S

A round 3/8” IC, single sided, CBN Insert. For use on aluminum blocks with iron liners and aluminum

heads with steel pre-combustion chambers. When cutting aluminum heads with pre-combustion

chambers it is best to use Rottler Manufacturing’s spray mist coolant system. RPM speeds with a 14”

cutter range from 650-750 RPM.

6303R

A round 3/8” IC, single sided, CBN Insert. For use on cast iron heads with steel pre-combustion

chambers. RPM speed with a 14” cutter range from 600-700 RPM and with a 18” cutter range from

500600 RPM.

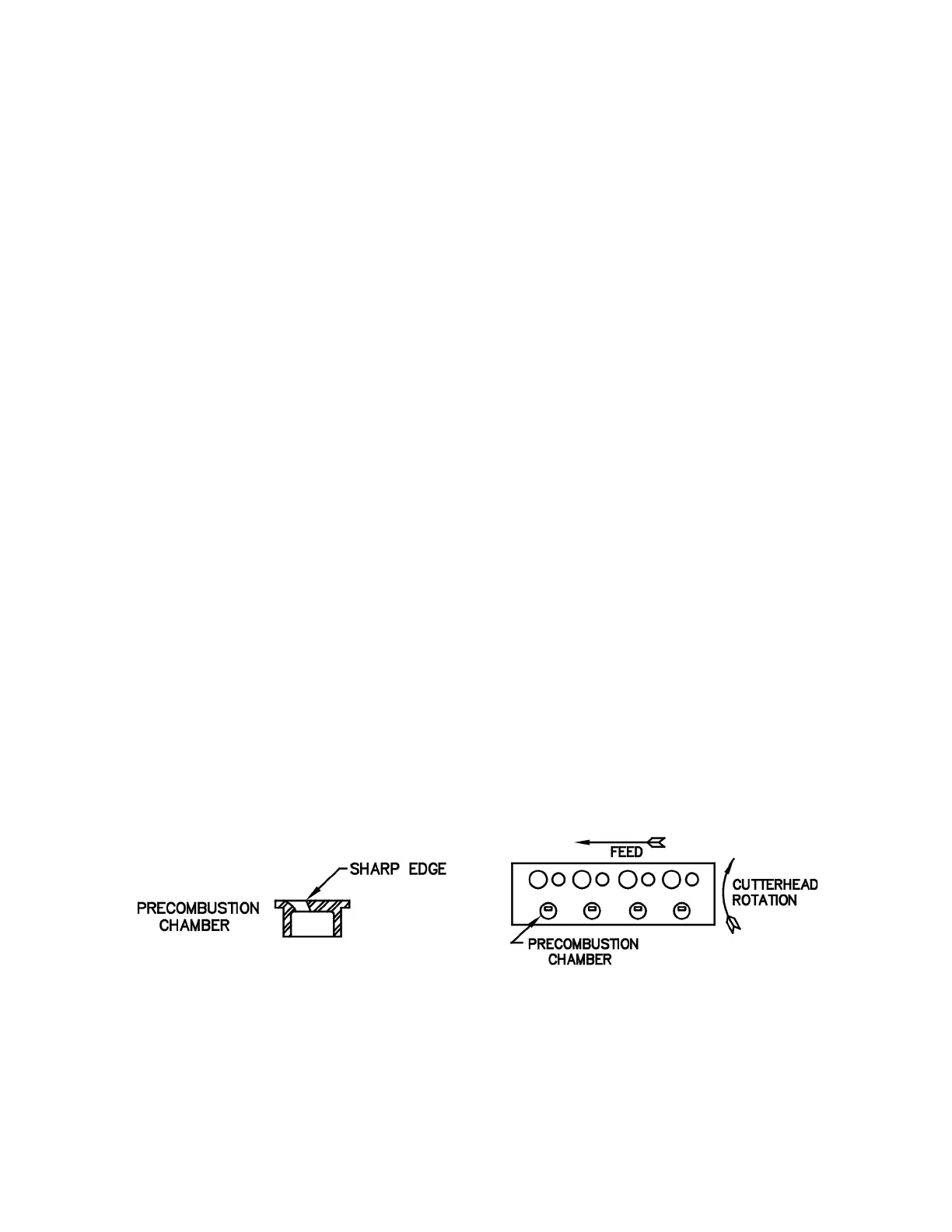

It is critical that the heads be mounted in the fixture correctly. If the head is not mounted in this way, the

inserts will chip when they contact the sharp of the pre combustion chamber.

Note: There are at least two different materials used in the manufacture of the pre-combustion

chambers. Rottler Manufacturing has experimented with only one of these materials. Rottler

cannot guarantee cutting all materials.

Loading...

Loading...