10

P/N 1011271 Rev. A 06/14

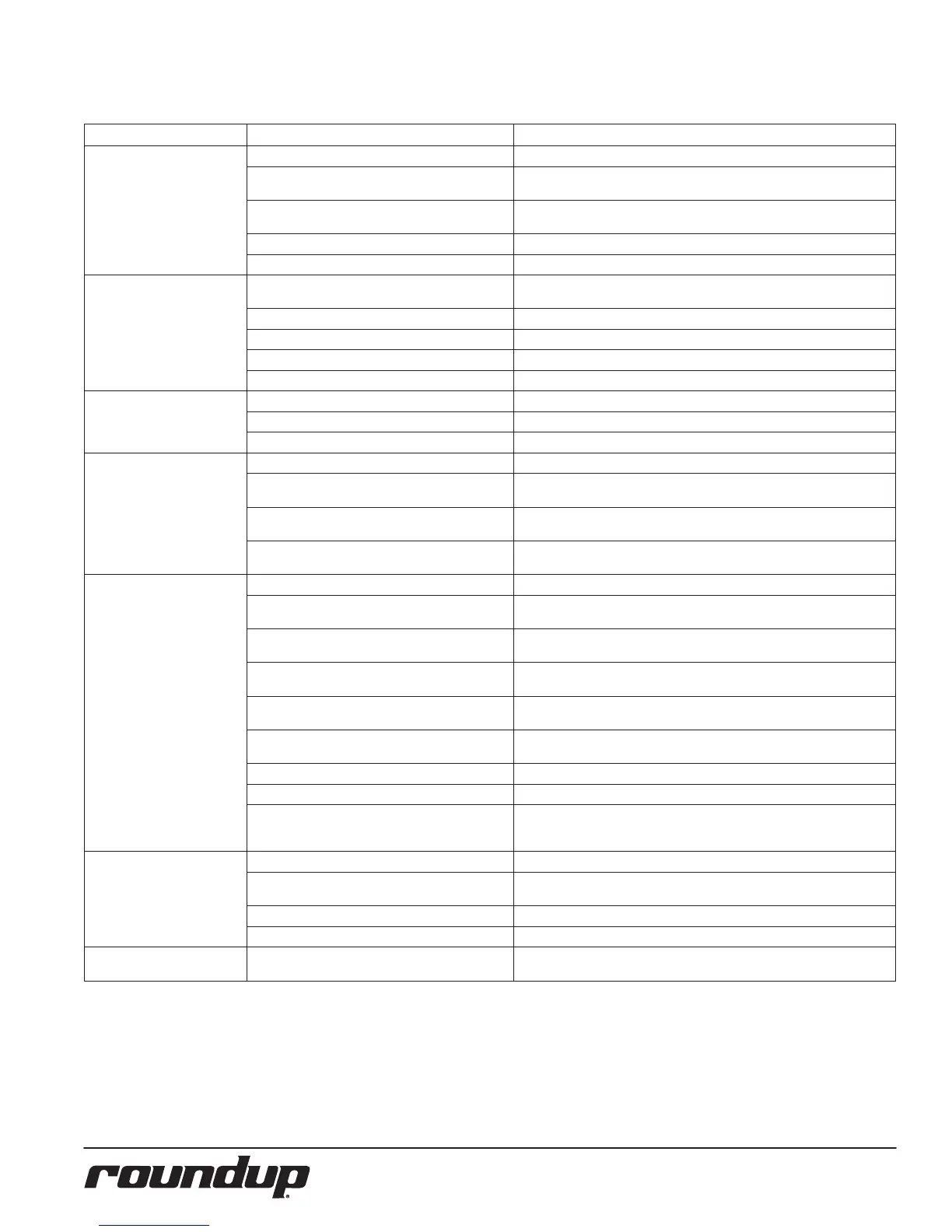

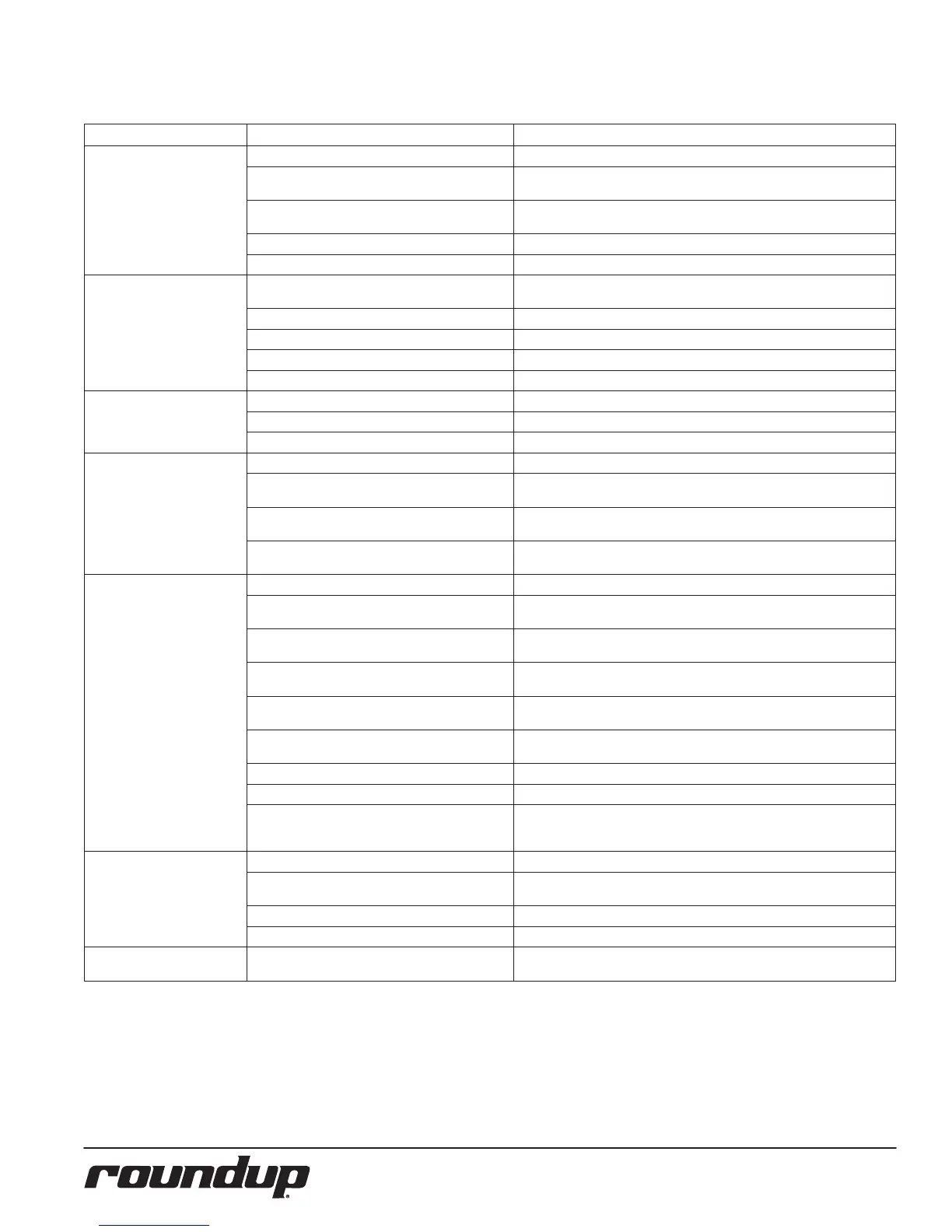

TROUBLESHOOTING

Problem Possible Cause Corrective Action

No Control Display

Power cord not plugged in Plug power cord into the proper electrical outlet

Hi-Limit has tripped

Allow unit to cool and reset the Hi-Limit Control. If it trips again, contact your

Maintenance person or Authorized Service Agency.

Circuit breakers turned o or tripped. Damaged electri-

cal outlet, plug, or cord. Power switch damaged

Reset circuit breakers. If they trip again, check the power cord,plug, and outlet for

damage. Contact your Maintenance person, Authorized Service Agency.

Faulty or mis aligned communication cable Replace or align communication cable

Faulty Transformer Replace transformer.

Conveyor does not turn on

Conveyor Belt/Chain has stretched. Chain skipping on

sprockets.

Measure and adjust the conveyor belt chains as described in the Maintenance

section of this manual.

Loose sprocket Verify setscrew is tight on at part of shaft.

Motor Drive Chain came o sprocket(s) Reinstall drive chain

Inernal part /object interfering within conveyor system Check for interference & clear up as necessary.

Dive chains need lubrication. Lubricate chain

Conveyor(s) hesitate

Loose or misaligned sprocket Align and tighten set screw on sprocket

Motor drive chain loose or stretched Replace or tighten up slack on drive chain.

Drive motor(s) have failed Contact your Maintenance person or Authorized Service agancy for service

Buns not toasting adequately

Compression settings are incorrect. Use the recommended settings.

Release sheet is worn or needs cleaning (replace every

3-5 weeks)

Inspect release sheet for cleanliness, worn spots, wrinkles , or tears. Clean or

replace release sheet as described in the Maintenance section of this manual.

Silicone belts are worn or need cleaning (replace every

2-4 months).

Replace or clean Silicone belts as desribed in thw Maintenance section of this

manual.

Silicone belts are not tacky.

Replace or clean Silicone belts as desribed in thw Maintenance section of this

manual.

Crowns and/or Heels must be

forced into the toaster. Buns

sticking and burning.

Silicone belts not being cleaned properly. Clean silicone belts as described in the Maintenance section of this manual.

Silicone belts are not tacky.

Replace or clean Silicone belts as desribed in thw Maintenance section of this

manual.

Silicone belts are dirty, worn, or damaged (replace every

2-4 months)

Replace or clean Silicone belts as desribed in thw Maintenance section of this

manual.

Release sheet is not being cleaned properly.

Clean both sides of release sheet as described in the Maintenance section of this

manual.

Release sheet is not being reversed as required.

Reverse the release sheet or replace release sheet as described in the Mainte-

nance section of this manual.

Conveyor Belt/Chains are skipping on sprockets.

Adjust the conveyor belt chains as described in the Maintenance section of t his

manual.

Drive motor stalls intermittently. Contact your Maintenance person or Authorized Service agancy for service

Compression settings are incorrect. Use the recommended settings (4).

Buns are not inserted into the toaster properly.

Muns & Bagels should be inserted in the top feeder (#1) with cut side up.

Crowns should be inserted in the middle feeder(#2) with the cut side down. Heels

should be inserted in the lowere feeder only(#3) with the cut side up.

Toaster making unusal sounds

Compression settings are too tight. Set bun thickness compression knobs to the correct setting.

Conveyor belt chains have stretched or adjusted incor-

rectly.

Adjust the conveyor belt chains as described in the Maintenance section of t his

manual.

Motor Drive chain needs lubrication. Lubricate chain

Conveyor shaft bearing is binding. Contact your Maintenance person or Authorized Service agency for service

Buns/muns/bagels getting

caught in bun chute area

Bun chute installed incorrectly Reinstall Bun chute with lip end facing down towards exit

Loading...

Loading...