20

COMPILER TECO/ATI ENDORSEDDATE

14.07.2003

REG. CODE

1-5302-612

MODEL N°

50894

DATE OF ISSUE

07-03

REVISION 00

X

13

14

15

16

d= 0,8 ÷1,0 d=1,3

After prolonged running of the engine the hammering of the valves

on their seats at high temperature tends to harden the faces of the

seats and makes manual grinding difficult. It is thus necessary to

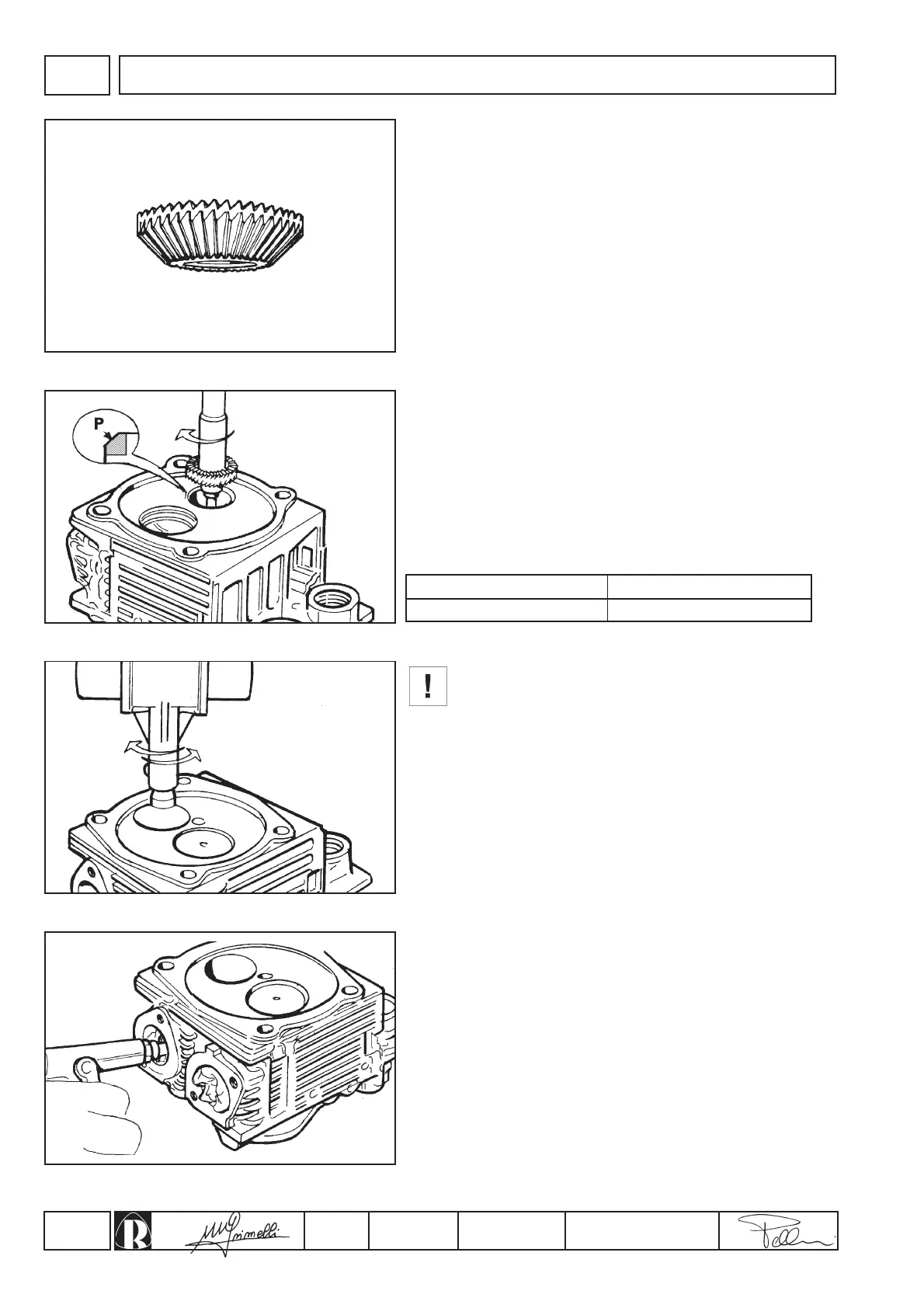

remove the hardened surface with a 45° cutter (fig. 13).

Grinding of valve seats causes a widening of the valve seat face P

(fig. 14).

Final lapping of the valve on the seat must be carried out by coating

the seat with a fine grinding paste and rotating the valve in a

clockwise and counterclockwise direction with slight pressure until

a perfect surface finish is obtained (fig. 15).

Observe the valve seating clearances indicated in the following

table (d, fig. 11).

Fitting mm Max. wear mm

In the case of lower values the valve may strike the piston.

In the case of values in excess of 1.3mm the valve seat

rings must be replaced.

Fitting of new seats or valves always requires preparatory grinding.

Valves are available with the external diameter increased by 0.5mm.

After grinding wash the valve and seat carefully with petrol or

paraffin in order to remove residual grinding paste and chips. Once

you have finished grinding check the efficiency of the seal between

the valve and seat as outlined below:

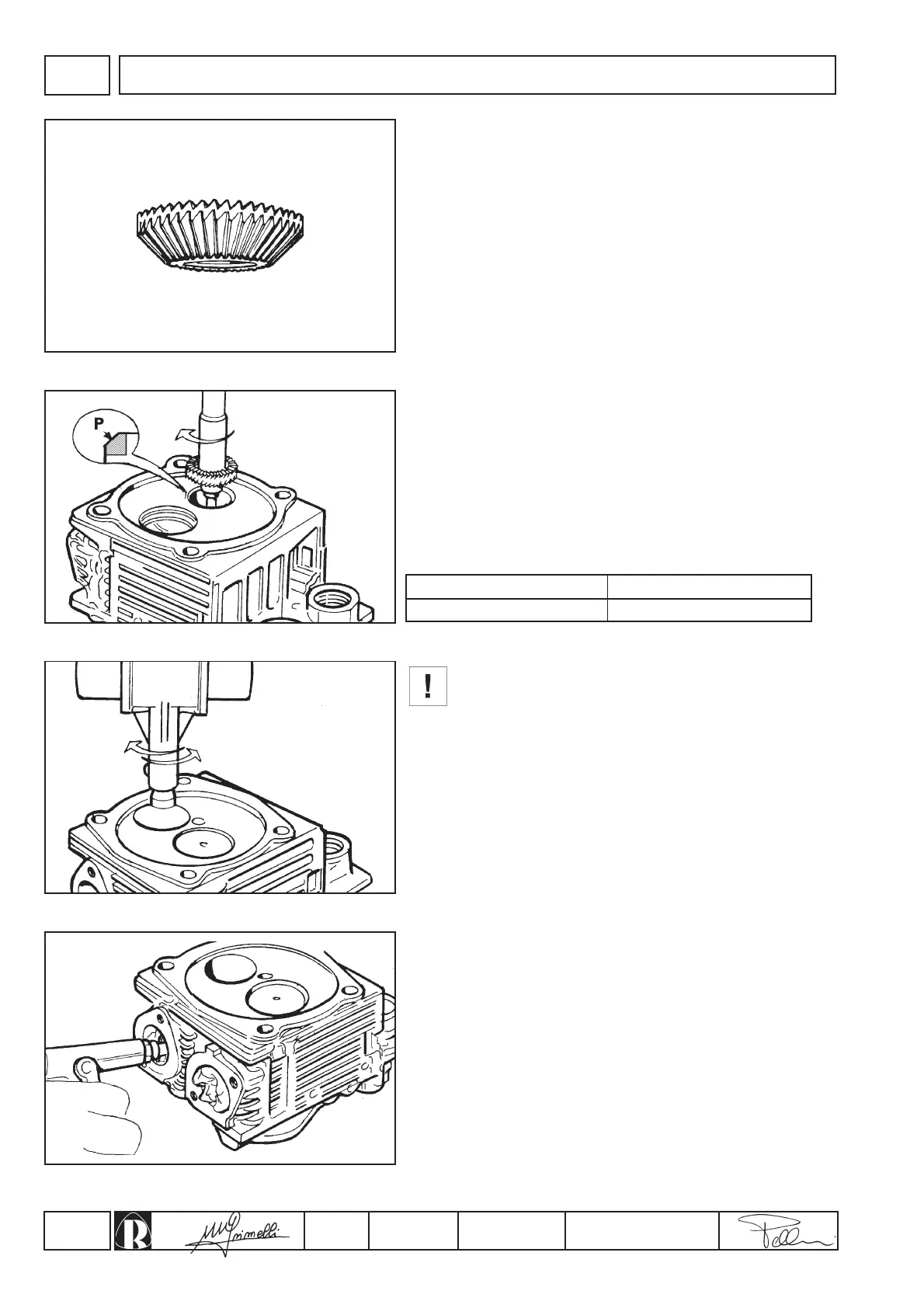

1.Fit the valve on the head with spring, washers and split cones

(fig 10).

2.Invert the head and pour in a few drops of diesel fuel or oil

around the edges of the valve head.

3.Blow compressed air into the inlet of the cylinder head taking

care to seal the edges so that the air does not escape (fig. 16).

Should air bubbles form between the seat and the valve remove the

valve and regrind the seat.

CHECKS AND OVERHAUL

Loading...

Loading...