24

COMPILER TECO/ATI ENDORSEDDATE

14.07.2003

REG. CODE

1-5302-612

MODEL N°

50894

DATE OF ISSUE

07-03

REVISION 00

X

29

30

31

32

A B

C

D

34,69 ÷ 34,74

35,00 ÷ 35,04

25,00 ÷ 25,20

0,040 ÷ 0,074

0,07 ÷ 0,105

0,07 ÷ 0,105

E

F

G

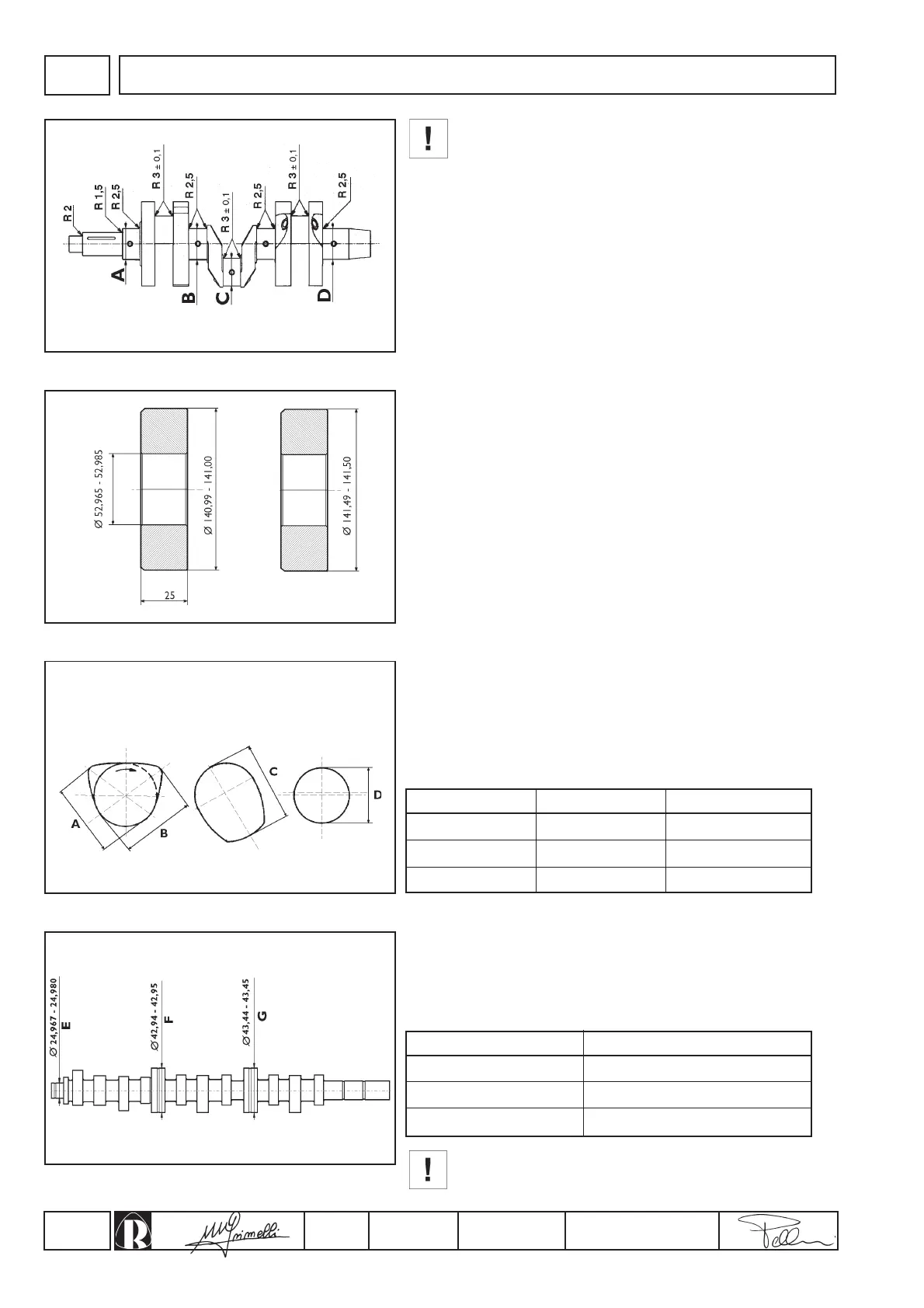

During grinding take care not to remove the shim

adjustment material from the main journal thrust face to

avoid changing the crankshaft end float; also ensure that

the grinding wheel radii are as specified in figure 29 so as

not to create crack initiation sections on the crankshaft.

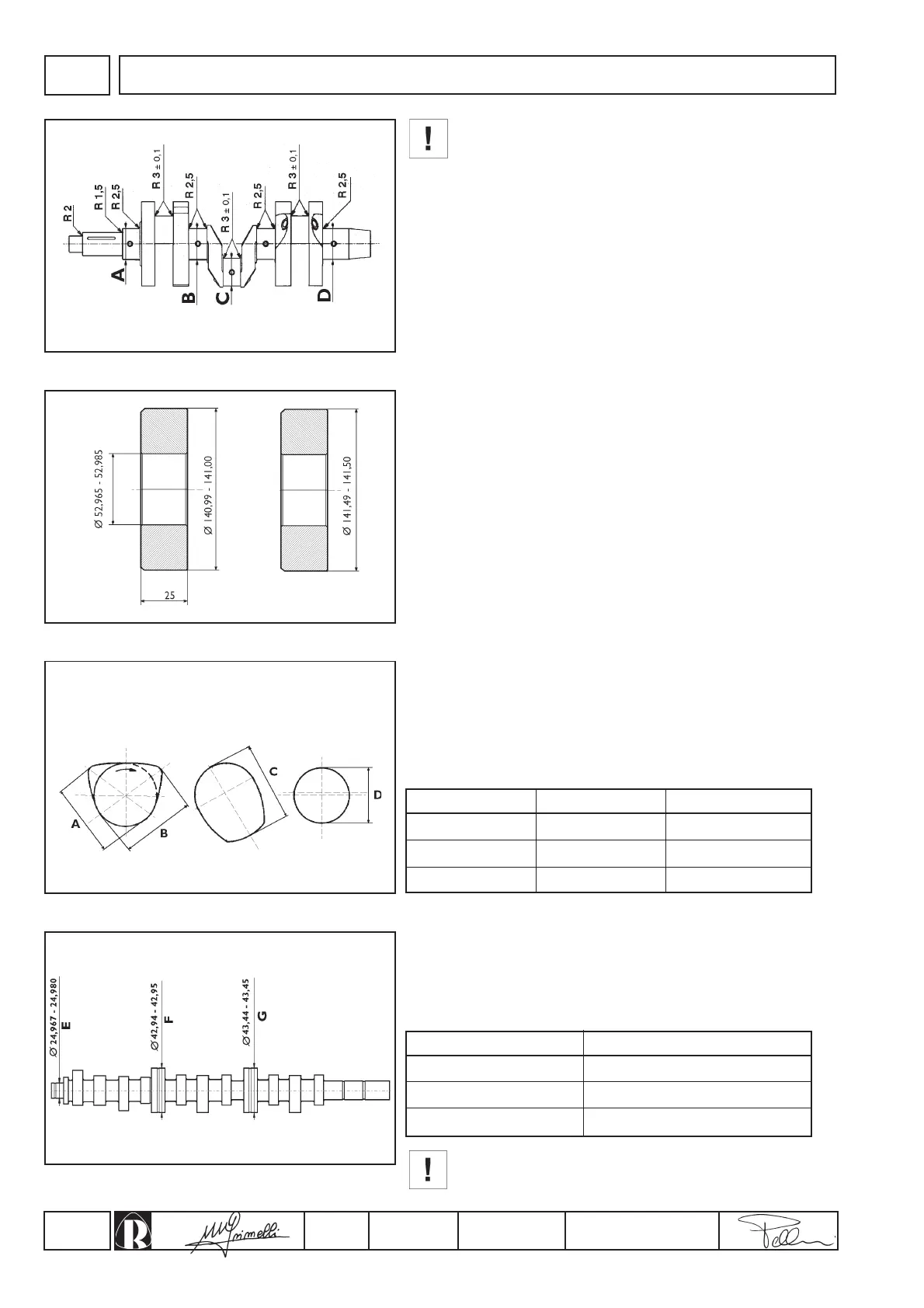

CHECKS AND OVERHAUL

Measurement Dimensions mmCam

Timing

Injection

Fuel pump

Measurement Clearance mm

Central main bearings

In order to facilitate assembly the central main bearings are of

different external diameters (fig. 30) and are machined with a

bevelled edge to assist their insertion into the crankcase.

Check the dimensions of the shells and renew them if they are

worn or deformed.

Also check the condition of the oil passages and, if necessary,

clean them with paraffin or petrol and dry with compressed air.

Oil seal rings

Check that the rings have not hardened around the internal contact

edge and that they show no signs of cracks or wear.

Camshaft

Check the cams and bearing journals for scoring and wear.

Measure the dimensions and compare them to the values in the

table below and shown if figures 31 and 32.

Camshaft dimensions fig. 31.

Renew the camshaft if the cams or journals show wear in

excess of 0.1mm.

Assembly clearance between the journals and their housings

should be (fig. 32):

inlet/exhaust injection feeding pump

Loading...

Loading...