34

COMPILER TECO/ATI ENDORSEDDATE

14.07.2003

REG. CODE

1-5302-612

MODEL N°

50894

DATE OF ISSUE

07-03

REVISION 00

XIII

73

74

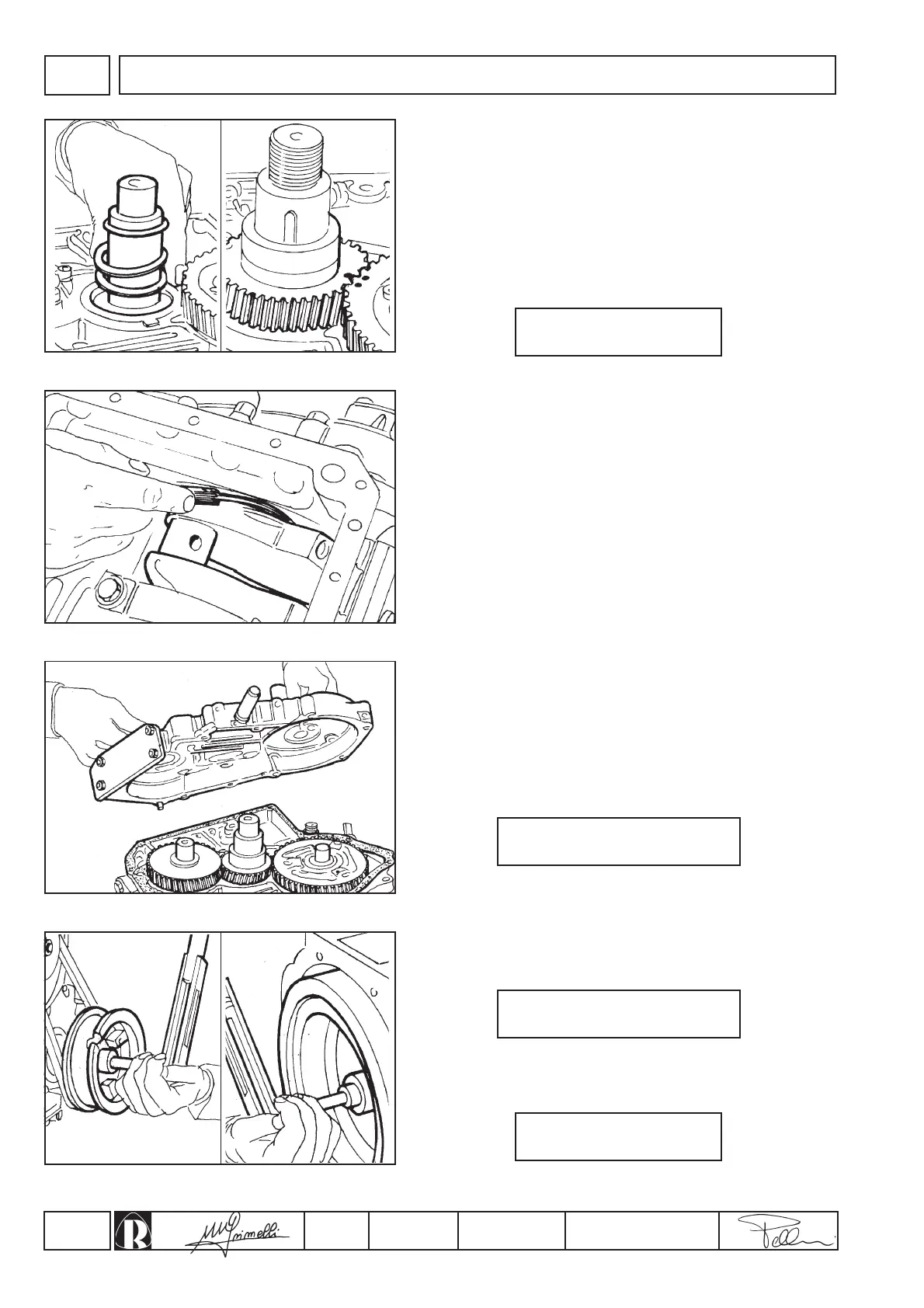

71 72

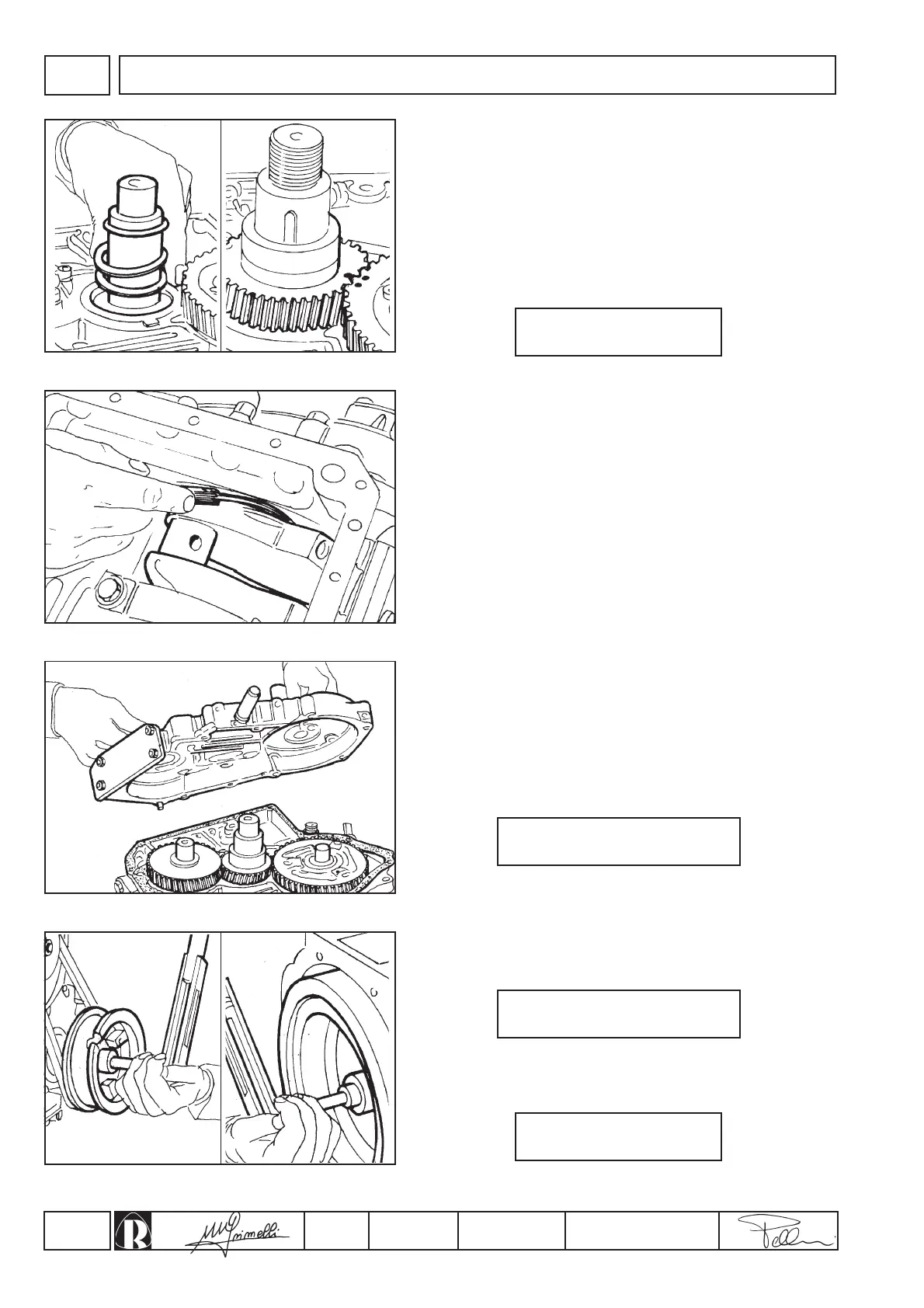

75

76

0,10 ÷ 0,25 mm

kgm 2,2 ÷ 2,4 (Nm 21,6 ÷ 23,5)

kgm 32 (Nm 314)

kgm 19 ÷ 22 (Nm 186,5 ÷ 216)

Fit the flywheel-housing and flywheel (fig. 76) and torque the latter

to:

Crankshaft end float

Once the crankshaft has been inserted into the crankcase, fit the

external clearance adjustment ring with the milled grooves facing

toward the timing gear. Also fit the brass shims, the O-ring (fig. 71),

the key, the timing gear - ensuring that the reference marks match

those on the camshaft gear (fig. 72), the pulley, and the washer, and

then tighten the nut securing the pulley.

Use a feeler gauge to check the clearance between the clearance

adjustment ring and the crankshaft (fig. 73); the value must be

within the range:

Pulley and flywheel

Tighten the pulley fixing bolt (fig. 75) to:

Timing cover

Check that the timing references punched on the camshaft and

crankshaft gears are mutually aligned (fig. 72).

Fit the oil seal onto the cover using a normal tubular punch of

appropriate diameter. Mount the cover to the crankcase (fig. 74) after

first inserting a gasket between the facing surfaces; tighten the

fixing screws to:

If the value is different, fit or remove the brass shims mounted

behind the crankshaft gear.

ENGINE ASSEMBLY

Loading...

Loading...