27 / 72

Horizontal End Suction Pump for Chemical Process, ASME B73.1-2001

Installation, Operation, and Maintenance Manual – CPP21

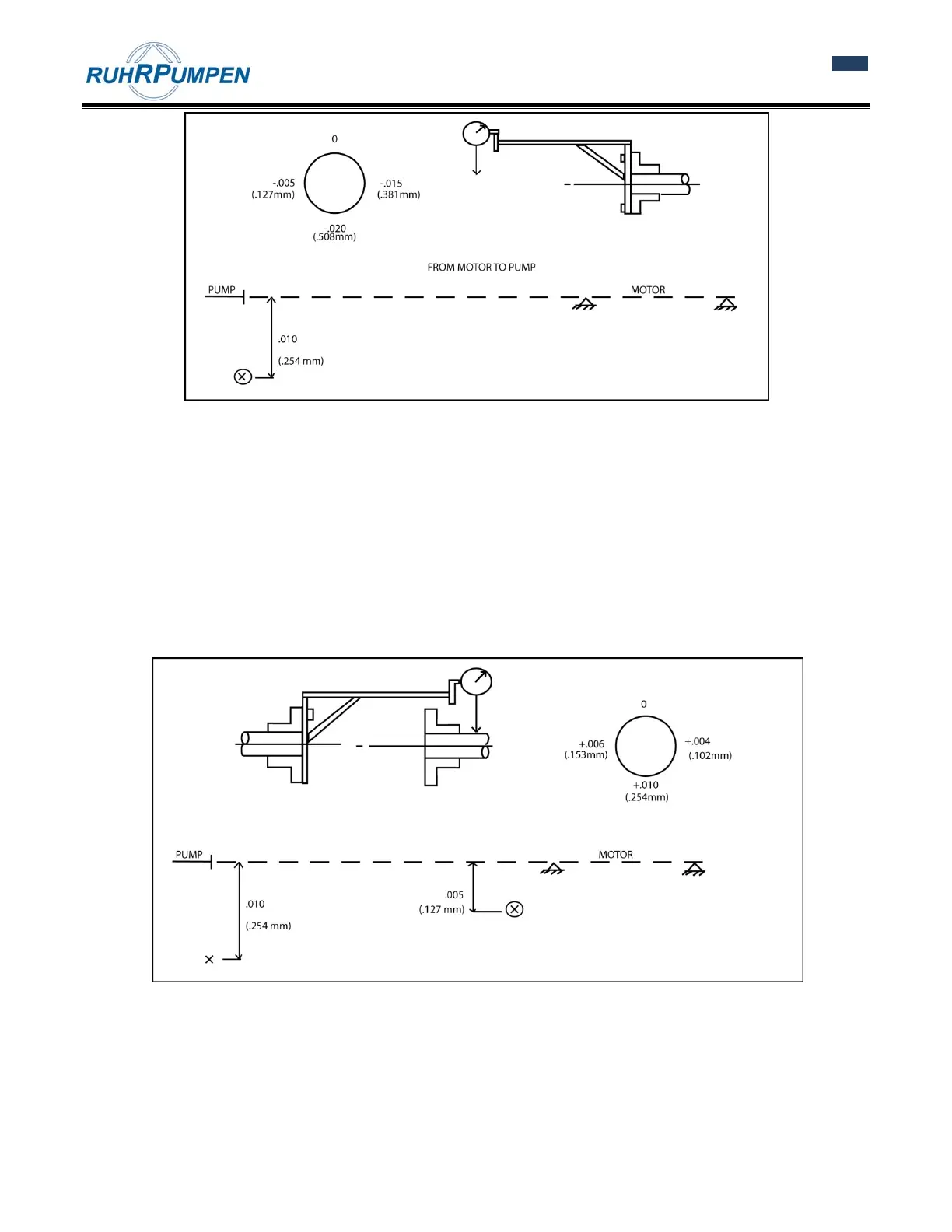

Figure 5.3 Motor shaft extension relative to the pump shaft center line.

Now with the indicator bracket attached to the pump hub reading off the motor hub, rotate unit again in 90°

increments. NOTE: If you can set up both indicators at once, both sets of readings can be taken at one time.

Bottom reading is then corrected for indicator sag. The -0.005 inch (-0.127 mm) was subtracted from the

+0.005 inch (+0.127 mm) indicator reading to give an actual +0.010 inch (+0.254 mm) reading.

The +0.010 inch (+0.254 mm) is divided by two to give +0.005 inch (+0.127 mm) which is the actual shaft

extension to shaft relationship.

In this case, a plus reading at the bottom indicates the motor shaft is low compared to the pump shaft

extension. Plot this point as shown in the example.

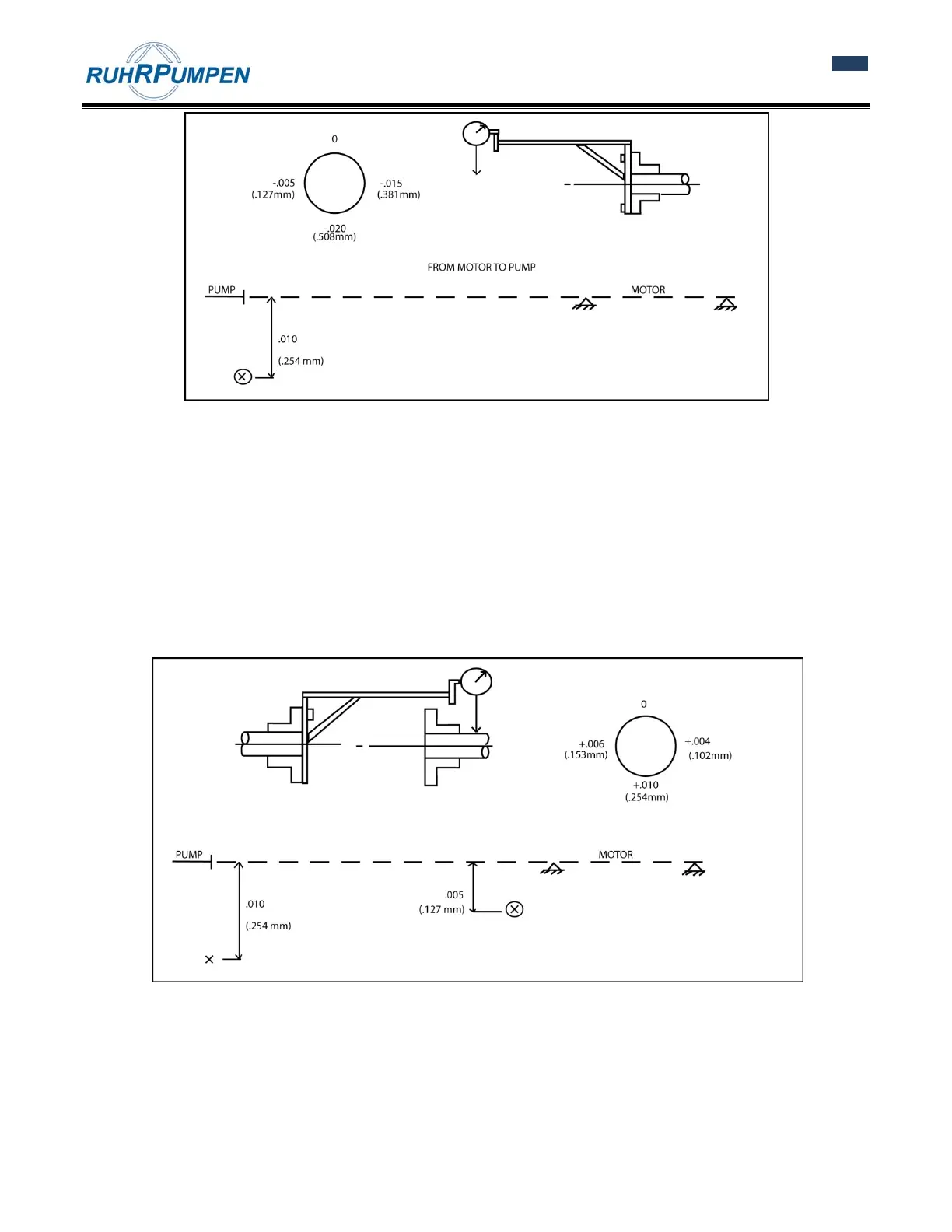

Figure 5.4 T.I.R. second reading.

We have now located the motor shaft theoretical extension in two places:

A. In the plane of the pump hub.

B. In the plane of the motor hub.

Loading...

Loading...