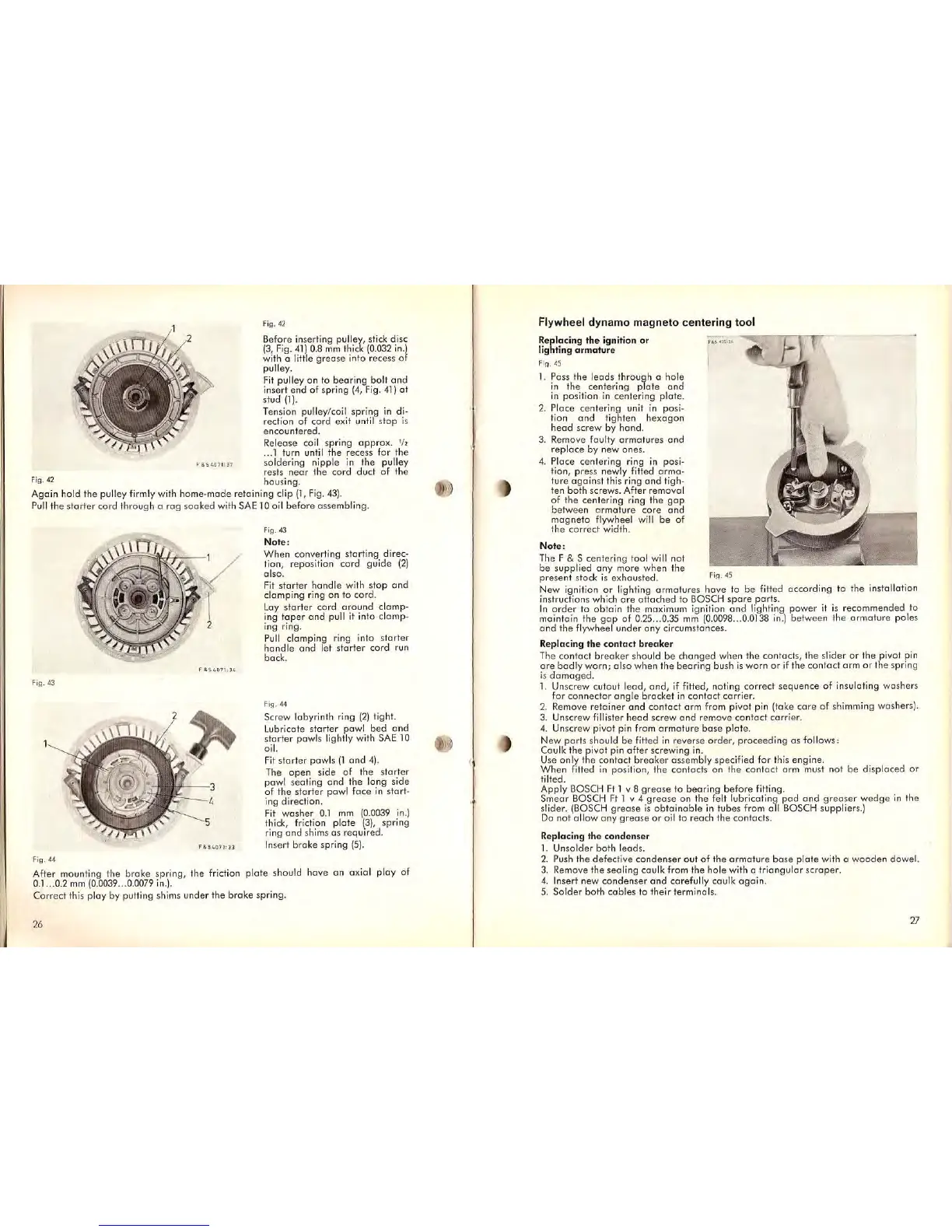

Fig.

42

Before inserting pulley,

slick.

di

sc

(3,

Fig.

41]

0.8

mm

thick

(0

.

032

in.)

wilh a little

grease

into recess of

pulley.

Fit

pulley on to bearing bo

lt

and

insert end

of

spring (4,

Fig

. 41]

01

stud

(1].

Tension pulley/coil spring

in

di-

rection

of

cord exil until slop is

encountered.

Release coil spring

opp

rox. 'II

... 1 turn until the recess for the

FOH

Q

lI

'"

soldering nipple

in

the pulley

resls

near

the cord duct of Ihe

f i

g.

42

housing.

Again hold the pulley firmly with home-made retaining clip

(1,

Fig.

43].

Pull

the starler cord through a

rag

soaked wilh

SAE

1 0 oil before assembl ing.

fig.

43

Fi

g.

44

fjg.43

Note:

When

converting starting dlrec-

lion, reposition cord gUide

(2)

olso.

Fit

starter

handle

with stop

and

clamping ring on to cord.

lay

starter cord

around

clamp-

ing

toper

and

pull

it

into clamp-

ing ring.

Pull

clamping ring inio starter

handle

and

let starter cord run

bock.

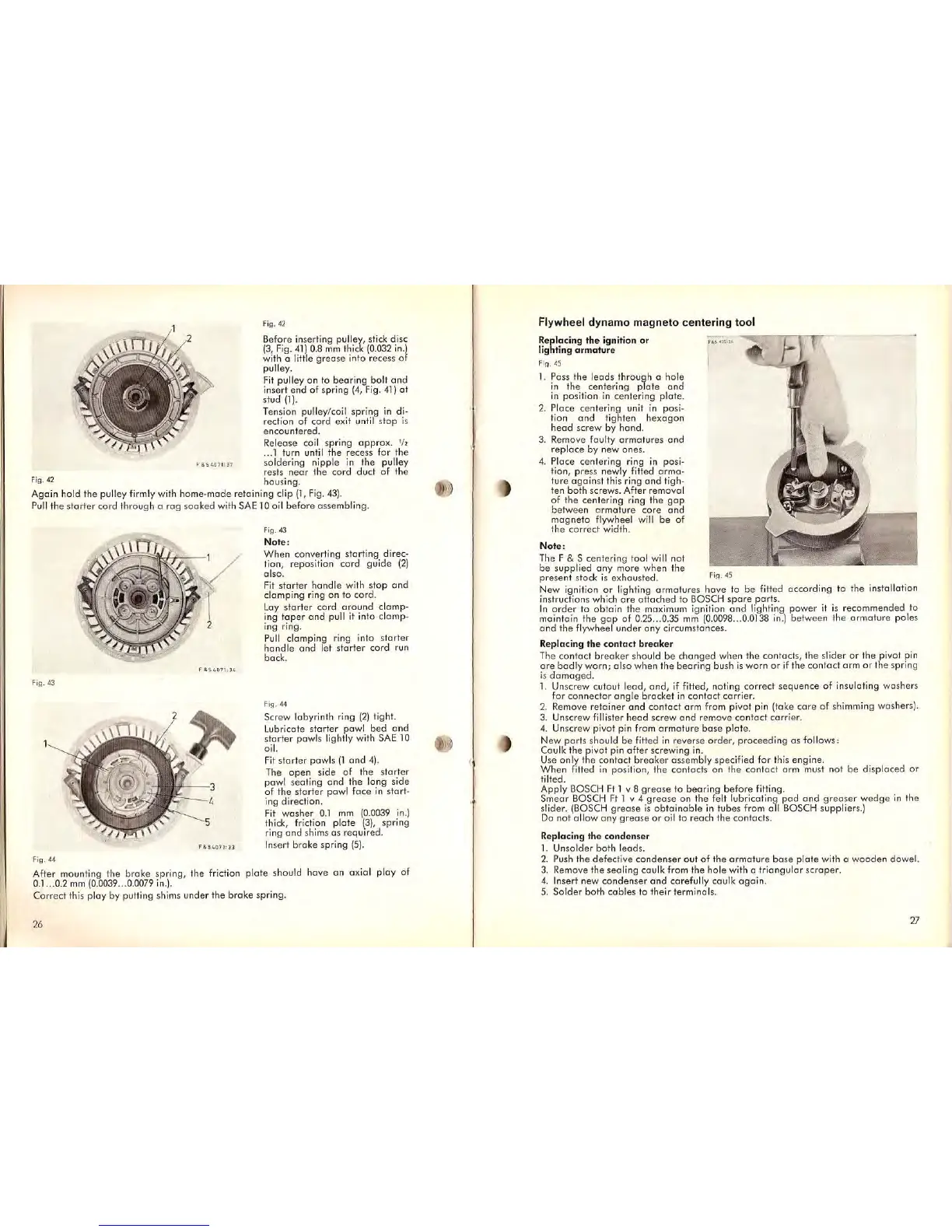

Fi

ll.

44

Screw labyrinth ring

(2)

tight.

lubrica

te storler powl

bed

and

start

er

pawls lightly with

SAE

10

oil.

Fi

t starter p

aw

ls

(1

and

4).

The

open

side

of

the starter

pawl seating

and

the l

ong

side

of

the starler pawl

face

in starl-

ing direction.

Fit

washer 0

.1

mm

(0.0039

in.)

thi

ck,

friction plate

(3),

spring

ring

and

shims as reqUired.

Insert

broke spring

(5].

After mounting Ihe broke spring, Ihe friction pla te should have on axial play of

0.

1 ... 0.2

mm

(0.0039

... 0.0079 in.).

Correct this ploy by putting shims under Ihe broke spring.

26

Flywheel

dynamo

ma

gneto

c

ente

r

ing

tool

Replacing

the

ignition

or

lighting

ormatur

e

f i

f!o

45

I.

Pass the l

eads

th

rough a hole

in

the centering pl

ale

and

in

position in centering plat

e.

2.

Place centering unit

in

posi-

tion

and

tighten hexagon

head

screw by hand.

3.

Remove foully armatures a nd

r

eplace

by new ones .

4.

Pl

ace

centering ring

in

posi-

tion, press newly fitted

arma-

lure

against

Ihis ring

and

ligh-

ten both screws. After removal

of

the centering ring the

gop

between

armature

core

and

magne

to flywheel w

il

l

be

of

the correct width.

Note:

--

,

..

. *,.

The F & S centering tool will not

be

supplied

any

more when the

present stock

is

exhausted. F

ig

.

45

New ignition

or

lighting

armatures

have to be fitted according to the installation

instructions wh i

ch

are

attached

to BOSCH

spore

parts.

In

order

to

ob

tain the maximum ignition

and

lighting power

it

is

recommended to

maintain the

gop

of

0.25 ... 0.35

mm

(0.0098

... 0.0138

in.

) between the

armature

poles

and

the flywheel

under

any

circumstances.

Replacing the contact breaker

The contact

breake

r should

be

changed

when the contacls, the slider

or

the pivot

pin

are

badly

worn; also when the

bearing

bush

is

warn

or

if

the

contact

arm or the spring

is

damaged.

1.

Unscrew cutout l

ead,

and,

if

fitted, noting correct

sequence

of

insulating washers

for connector

angle

brocket

in

cont

act

carrier.

2.

Remove r

etainer

and

contact

arm from pivot pin (take

care

of

shimming washers

].

3.

Unscrew fillister

head

screw

and

remove contact

car

rier.

4.

Unscrew pivot pin from

armature

bose plate.

New ports should be fitted

in

reverse

order,

proceeding as follows:

Caulk

the pivot pin

after

screwing

in.

Use only the contact

breaker

assembly specified for this engine.

When

fitted

in

position, the contacts on the contact

arm

must not be displ

aced

or

ti

lted.

Apply

BOSCH Ft1 v 8

grease

to

bearing

before

fitting.

Smear

BOSC

H

Ft

1 v 4

grease

on the felt lubricating pod

and

greaser

wedge

in

the

slider.

(BOSCH

grease

is

obtainable

in

tubes from all BOSCH suppliers.]

Do

not allow

any

grease

or

oil to reach the contacts.

Replocing the condenser

I. Unsolder both leads.

2.

Push the

de

fective

condenser

out of the

arma

ture bose plate with 0 wooden dowel.

3.

Re

move the sealing caulk from the hole with a triangular scraper.

4. Insert new conde nser

and

ca

ref

ull

y caulk

again.

5. Solder both cables to their terminals.

27

Loading...

Loading...