Replacing the magneto

housing

or

the

flywheel

2-

->~·

fi~.

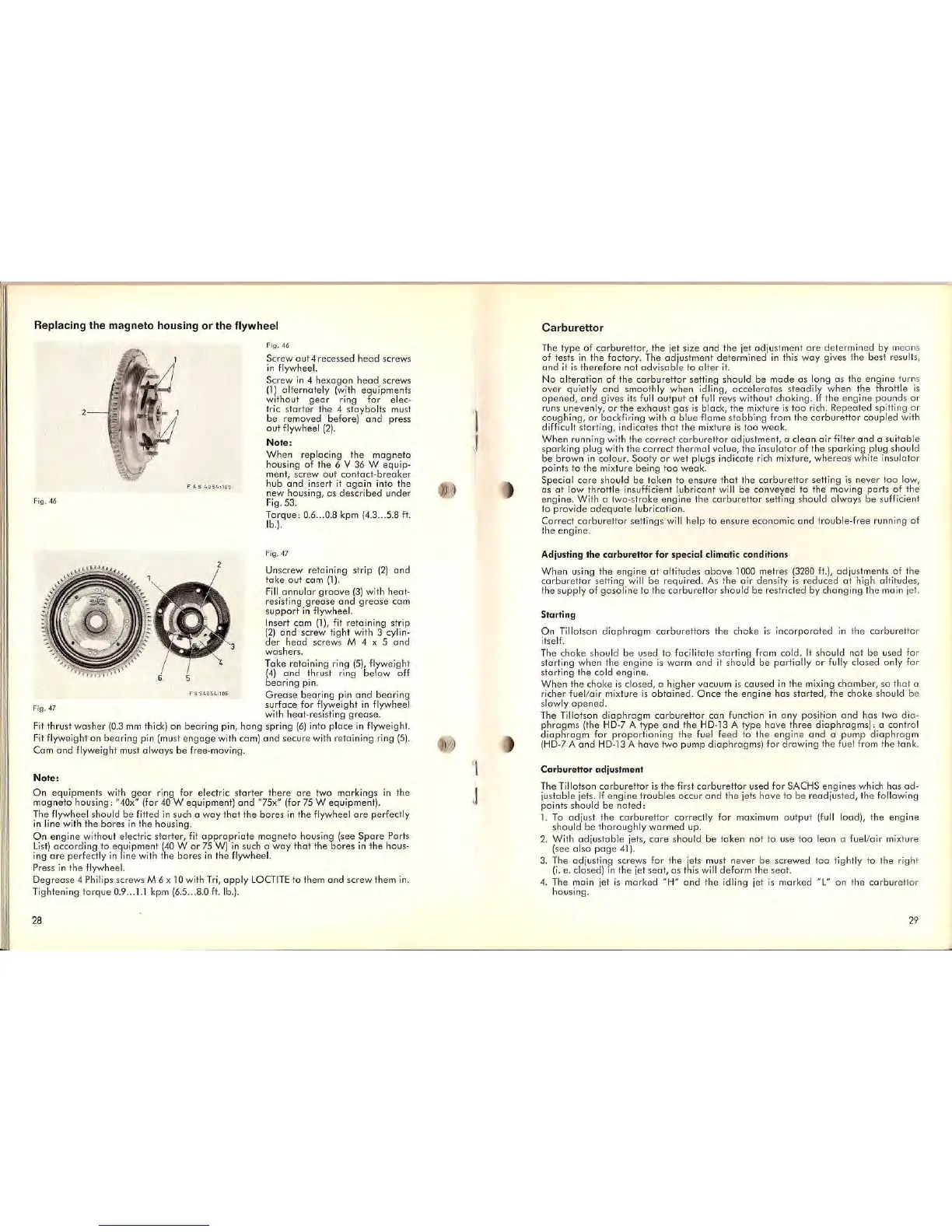

46

fig

. 47

Fig.

46

Screw

ou

t 4 recessed

head

screws

in

flywheel.

Screw

in

4 hexagon heod screws

(1)

alternately

(with equipments

wi

thout

gear

ring for elec-

tric

starte

r the 4 staybalts must

be

removed before)

ond

press

out

flywheel

(2).

Note:

When

replacing the

magneto

housing

of

the 6 V

36

W equip-

ment, screw

out

contact-breake

r

hub

and

insert

it

ogoin

into the

new housing,

as

described under

Fig.

53.

Torque:

0.6

...

0.8

kpm

(4.3

...

5.8

ft.

lb.).

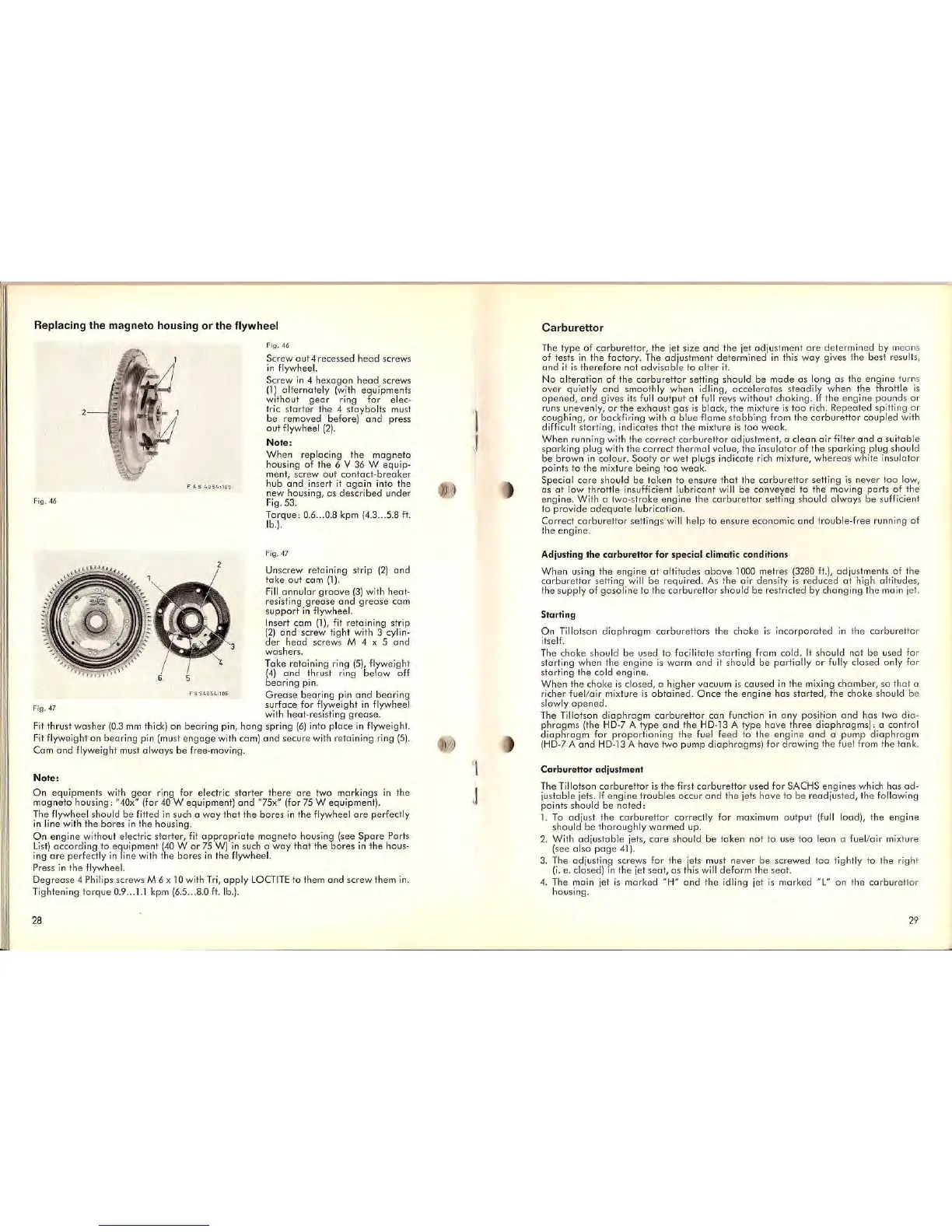

Fig.

47

Unscrew retaining strip

(2)

and

t

ake

aut

cam (I),

Fill

annular

groove

(3)

wi

th heat-

resisting

grease

and

grease

cam

support

in

flywheel.

Insert

cam (1

),

fit

retaining strip

(2)

and

screw tight with 3 cylin-

der

head

screws M 4 x 5

and

washers.

Take retaining ring

(5),

flyweight

(4)

and

thrust ring below off

bearing

pin.

Grease

bearing pin

and

bearing

surface

for flyweight

in

flywheel

with heat-res

isti

ng

grease.

Fit

thrust washer

(0.3

mm

thi

ck)

on bearing pin,

hang

spring

(6)

into place

in

flyweight.

Fit

flyweight

on

bearing pin (m

us

t

engage

with cam)

and

secure with retaining ring

(5

).

Cam

an

d flyweight must always be free-moving.

Note:

On

equipments

wi

th

gear

r

in

g for electric start

er

there

are

two markings

in

the

magneto housing:

-40x' (for

40

W equipment)

and

-7

5x

H

(for

75

W equipment).

The flywheel should be fitted

in

such a way that the bores

in

the flywheel

are

perfectly

in

line with the bores

in

the housing.

On

engine without electric starter, fit

appropriate

magneto

housing (see

Spare

Parts

List)

according to equipment

(40

W

or

75

W)

in

such a

way

that the bores

in

the hous-

ing

are

perfectly

in

line with the bores

in

the flywheel.

Pr

ess in the flywheel.

Degrease

4 Philips screws M 6 x

10

with

Tri,

apply

LOCTITE

to them

and

screw them

in.

Tightening

torque

0.9

...

1.1

kpm

(6.5

... 8.0

ft.

Ib,),

28

I

J

'I

Carburettor

The type

of

carburettor,

the jet size

and

the jet adjustment

are

determined by means

of tests

in

the factory. The adjustment

de

termined

in

this way gives the best results,

and

it

is

therefore not

advisable

to

alter

it.

No

alteration

of

the

carburettor

setting should be mode os long

as

the

eng

ine turns

over quietly

and

smoothly when idling,

accelerates

steadily when the

th

rottle

is

opened,

and

gives its full

output

at

full revs without choking.

If

the engine pounds

or

runs uneven

ly

,

or

the exhaust

gas

is

black, the m

ix

ture

is

too rich. Repeated spitting

or

coughing,

or

back

fi

ring with a blue flame

stabb

ing from the

carbureltor

coupled with

difficult starting, indicates

that

the mixture

is

too

wea

k.

When

running with the correct

corburettor

ad

jus

tment, a

clean

air

fi

lt

er

and

a suitable

sparking

pl

ug with the correct thermal value, the insulator of the sparking plug should

be brown in colour. Sooty

or

wet plugs indicate ri

ch

mi

xture,

whereas

white insulator

points to the mixture being too

weak.

Special

core

should be token to ensure that the corburetlor setting is never too low,

as

at

low throttle insufficient lubricant will be conveyed to the moving parts of the

engine. With a two-stroke engine the

carburettor

setting should always be sufficient

to provide

adequate

lubrication.

Correct

carburettor

settings will help to ensure economic and trouble-free running

of

the

engine.

Adjusting the

carbureltar

for

special

climat

ic

conditions

When using the

engine

at

al

ti

tudes

above

1Qoo

metres

(3280

ft.), adiustments of the

carbure

ttor setting will be required.

As

the

air

density

is

reduced

at

high alti tudes,

the

supp

ly

of

gasol

ine to the corburellor should be restricted by changing the main jet.

Starling

On

Tillotson

diaphragm

carburellors the choke

is

incorporated

in

the

carburettor

itself.

The choke should

be

used to facilitate starting from cold.

It

should not

be

us

ed

for

starting when the engine

is

worm

ond

it should be

pa

rtially

or

fully closed only for

starting the cold engine.

When

the choke is closed, a higher vacuum is caused

in

the mixing ch

amber,

so that a

richer fuel/air

mix

ture is

obtained.

Once

the

engine

has started, the choke should be

slowly

opened.

The Tillotson

diaphragm

carburettor

can

function

in

any

position

and

has two

di

a-

phragms

(the HO-7 A type

and

the HO-13 A type h

ave

three

diaphragms):

a control

diaphragm

for proportioning the fuel feed to the engine

and

a pump

diaphragm

(HO

-7 A

and

HD

-

l3

A h

ave

two pump

diaphragms)

for

drawing

the fuel from the tank.

CarbureHor adjustment

The Tillotson

carburellor

is

the first corburellor

us

ed

for SACHS engines which has ad-

justable jets.

If

engine

troubles occur

and

the jets have to be readjusted, the following

points should be noted:

1.

To

adjust the

carburettor

correctly for maximum

ou

tput (full load), the engine

should be thoroughly wormed up.

2.

WHh

adjustable

jets,

core

should be token not to use too leon a fuel/air mixture

(see also

page

41).

3.

The adjusting screws for the

je

ts must never be screwed too tight

ly

to the right

(i.

e. closed)

in

the jet seat,

as

this

will

deform the seat.

4.

The main jet

is

marked "

Wan

d the idling jet is marked

"l"

on

the

carburetto

r

housing.

29

Loading...

Loading...