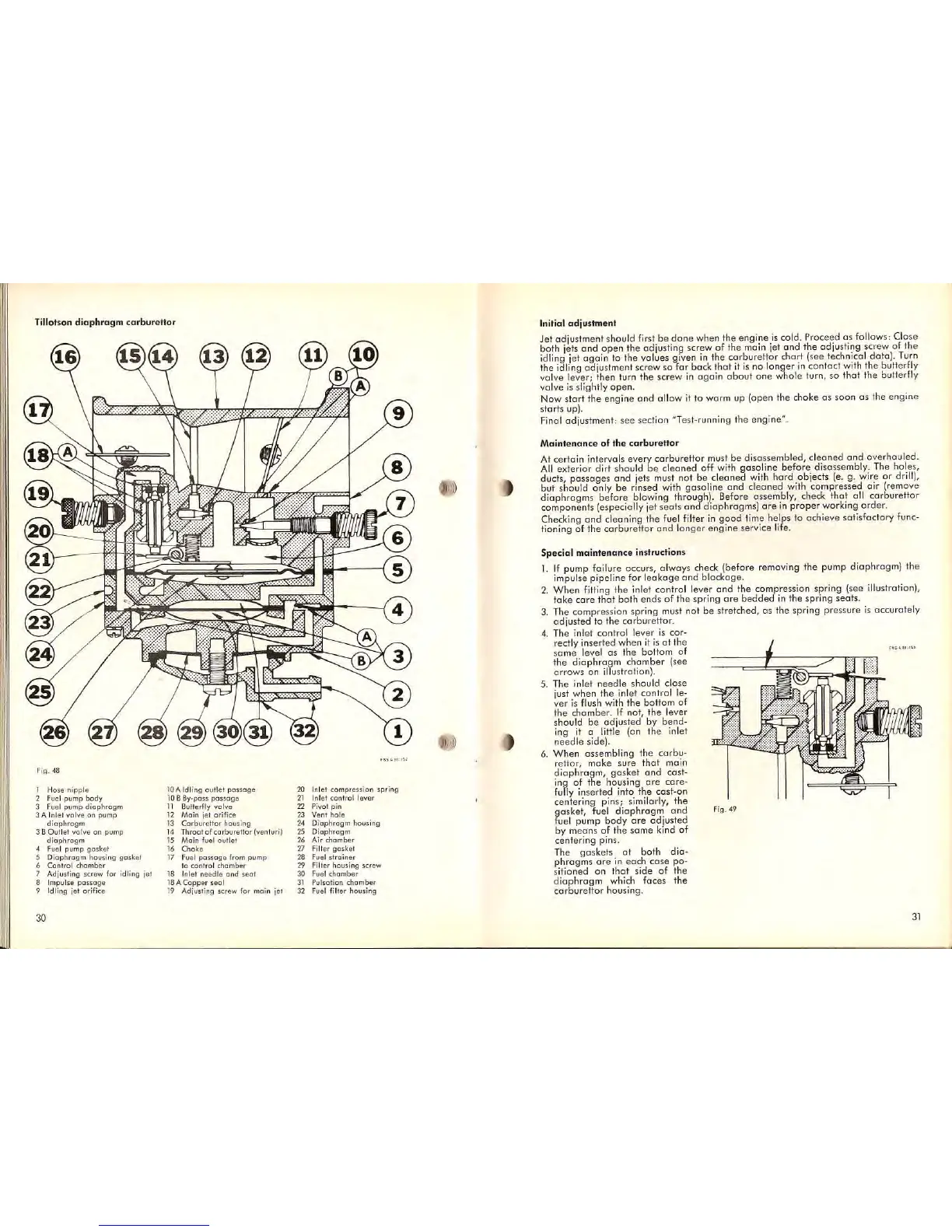

Tillotson

diaphragm

ca

rbur

etlo

r

Fiq

.48

I

Ho.e

nipple

2 Fuel pump

body

3 Fuel pump

diap

hragm

3 A

In

let

"alve

on

pu

mp

di

aphragm

3 B Outl

et

valve on p

um

p

diaphragm

4 Fuel pump

ga.ke

t

5 Di

aphragm

hous

in

g gasket

(;

Control <flomber

7

Ad

iu.ting sCrew

lo

r idling j

et

8 Impulse

passage

9

Id

ling iet

orilice

30

lOA Idlin g outlet

pO$Soge

10

B By_pass p

o"ag

e

11

Bunerily valve

12

Main iet orif

ic

e

13

Corbu rettor housing

14

Throato

l

corb

urenor

Ive

ntur

i)

15 Main luel o

ull

et

16

Choke

17

fuel

passage

from

pu

mp

to control chamber

18

Inl

et needle and

.eat

1

8ACopper

seal

19 Adiusting screw lor main iet

"

..

..

,"

20

In

let compre

..

i

on

sp

ring

21

Inl

et conlrol lever

22 Pivot pin

Z3

Venl hole

24

Di

ap

hragm hous

in

g

25

Diaphragm

26

Air <flamber

V Filter

go.k.,

28

Fu

el

stmine,

'l'I Filter housing sere

'"

3(} Fuel chamt.er

31

Pu

ls

ation

chamber

32

Fuel

fil

ter housing

Initial adjustm

en

t

Jet

adjuslmenl should first

be

done

when the

engine

is

cold. Proceed

as

follows: Close

both jets

and

open

the adjusting screw

of

the main jel

and

the

ad

ius ling screw

of

the

idling jet

again

10

the values given

in

the

carburettor

chart (see technical

data).

Turn

Ihe idling odiustment screw so for

bock:

that

it

is

no longer

in

conlact

with the butterfly

valve lever; then

tu

rn the scr

ew

in

again

about

one

whale turn, so that

th

e butterfly

valve

is

slight

ly

open.

N

ow

stortthe

engine

and

allow it to warm up (open Ihe choke

as

soon

as

the

engine

starts up).

Final adjustment: see section

-Test-running the engine"

Maintenance

of the

carburellor

At

ceria

in

intervals every

carburetlor

must

be

disassembled,

cleaned

and

overhauled.

All

exterior dirt should

be

cleaned

off with

gasoline

before

disassembly. The holes,

ducts,

passages

and

jets must not be

cleaned

with

hard

objects

(e

. g. wire

or

drill),

but should only

be

rinsed with

gasoline

and

cleaned

with compressed

air

(remove

diaphragms

before

blowing through). Before assembly, check

that

all

carburetto

r

components

(especially jet

se

ats

and

diaphragms)

are

in

proper

working

order.

Checking

and

cleaning the fuel filter

in

good

time helps to achi

eve

satisfactory func·

tioning of the

carburellor

and

longer engine service life.

Special maintencmce instructions

1.

If

pump failure occurs, always check (before removing the pump

diaphragm)

the

impulse pipeline for

leakage

and

blockage.

2.

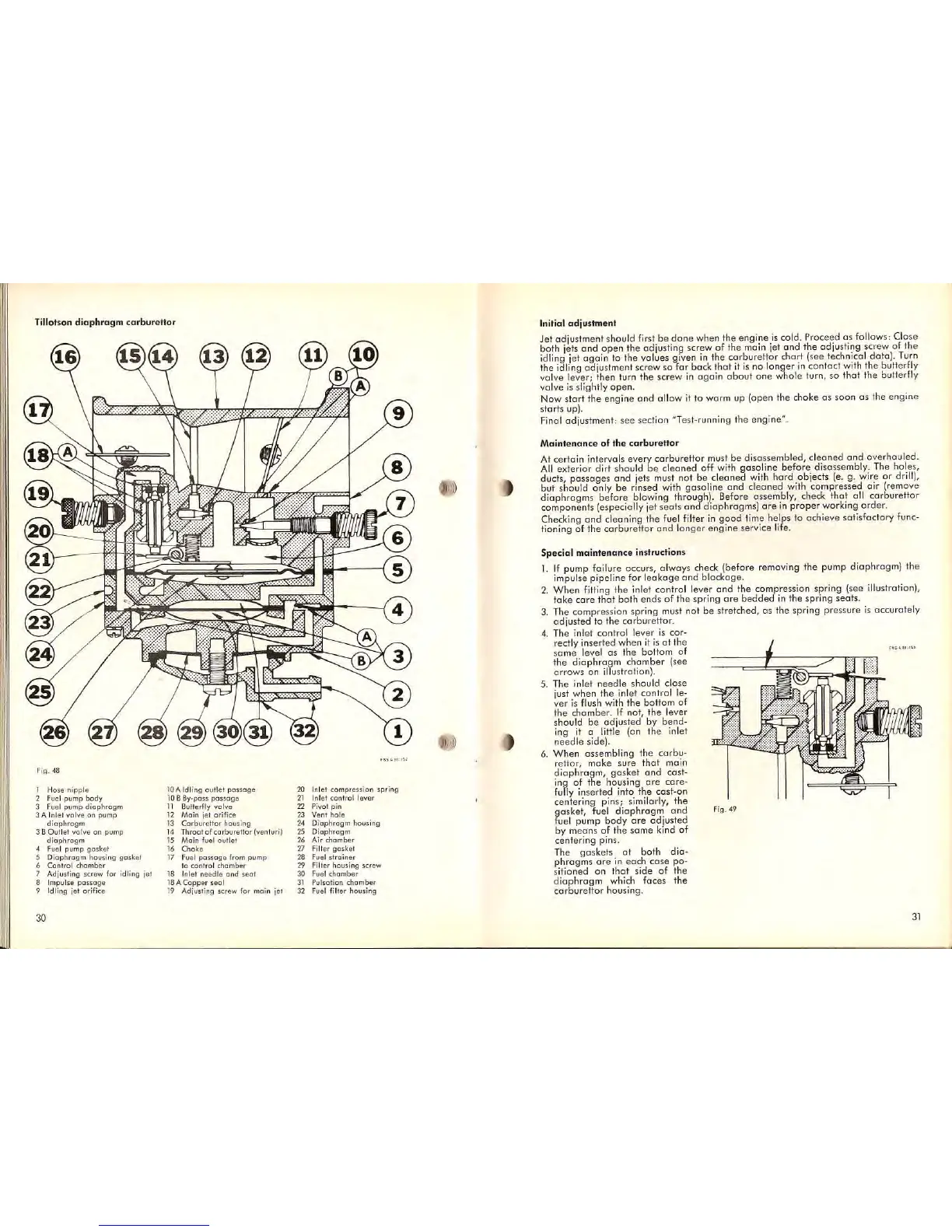

When

filling the inlet control lever

and

the compression spring (see illustration),

take

care

thai both

ends

of

Ihe spring

are

bedded

in

the spring seats.

3.

Th

e compression spring musl not be stretched,

as

the spring pressure

is

accurately

adjusted

to Ihe carbureltor.

4.

The inlel control lever

is

cor-

rectly inserted when

it

is

atthe

same

level

as

the bottom

of

the di

aphra!m

chamber

(see

arrows

on

il

uslration).

5.

Th

e inlet needle should close

just when the inlet control le-

ver

is

flush with the boltom

of

the enamber.

If

not, Ihe lever

should

be adjusted by bend-

in

g

it

a liltle (an the

in

let

needle side).

6.

When

assembling Ihe carbu-

retlor, make sure

that

main

diaphragm

,

gasket

and

cast-

ing

of

the housing

are

care-

fu

l

ly

inserted into the cast-on

centering pins;

similarly, the

gasket,

fuel

diaphragm

and

fuel pump body

are

adjusted

by

means

of

the

same

kind

of

centering pins.

The gaskets

at

both

dia·

phragms

are

in

eaen

case

po·

sitioned

on

that side

of

the

diaphragm

which faces the

carburellor

housing.

,"'

"

..

"

Fig.

49

31

Loading...

Loading...