nsu,

.,

u

Fig.

32

FtS

' )(1"15

fig

.

33

22

Fig.

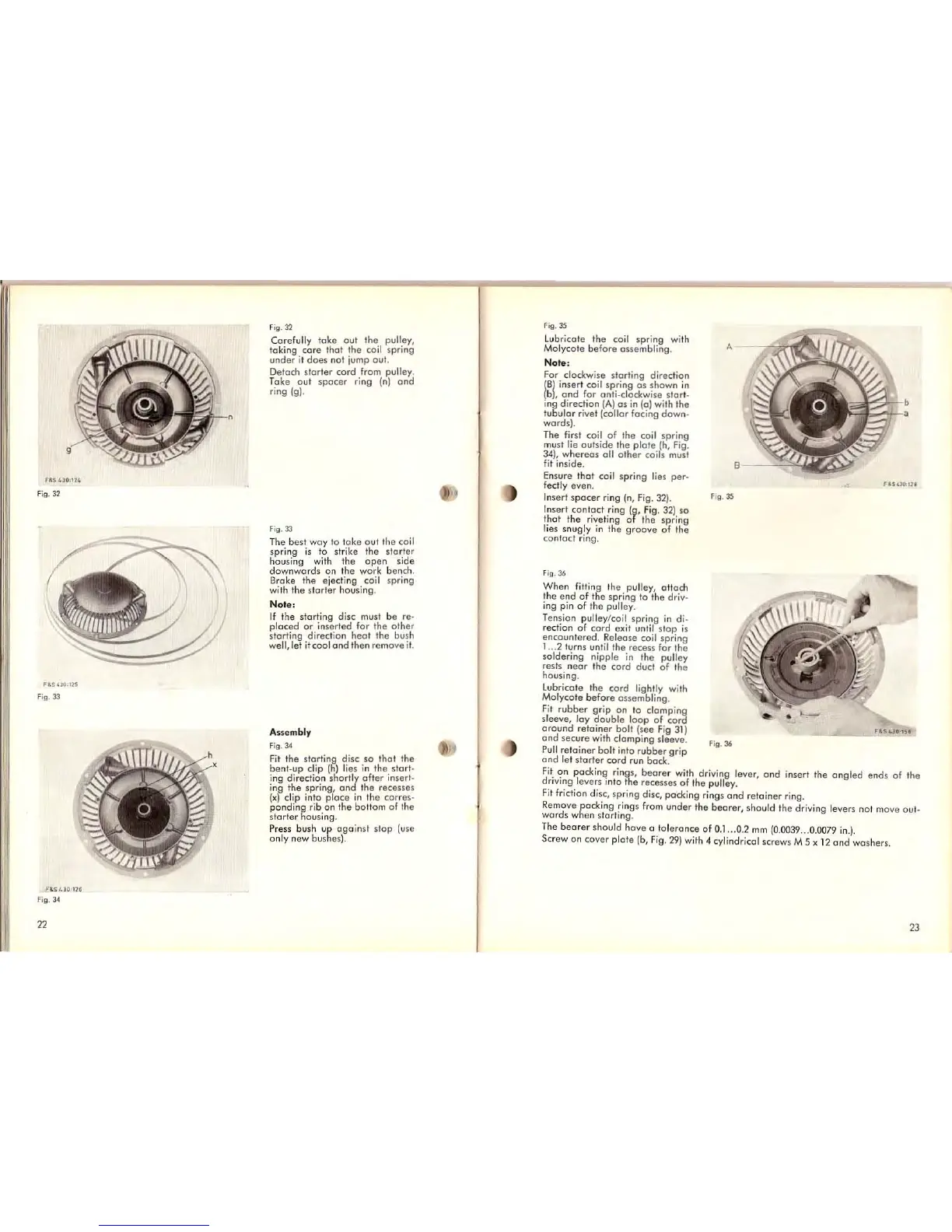

32

Carefully

take

aut

the.

pull.ey,

taking

ta

re that the cod spring

u

nder

it does nat jump aut.

Detach starter

tord

from pulley.

Take out

spacer

ring (n)

ond

ring (g

).

f ig.

33

The best way

10

take

a

ut

th

e cod

spring

is

to strike the storter

housing with the

open

side

downwards on

th

e work bench.

Broke the ejecting coil spr

in

g

with the start

er

housing.

Nole:

If

the slorling disc must be re·

placed

or

in

serted for the

ot

h

er

starting direcl

io

n

heat

the bush

well, lei

ilcoo

l

and

then remove it.

As

se

mbly

Fig.

3-1

F

it

the slarling disc

50

that the

bent.up clip

(h)

lies in

Ihe.slarl.

ing direction shortly

afler

In

sert·

ing the spr

in

g, a nd the recesses

(x)

cl

ip into

place

in

Ihe corres·

ponding

ri

b.on the bollom

of

Ihe

starter

hOUSing.

Press bush up

aga

in

sl

slop (use

only new bushes).

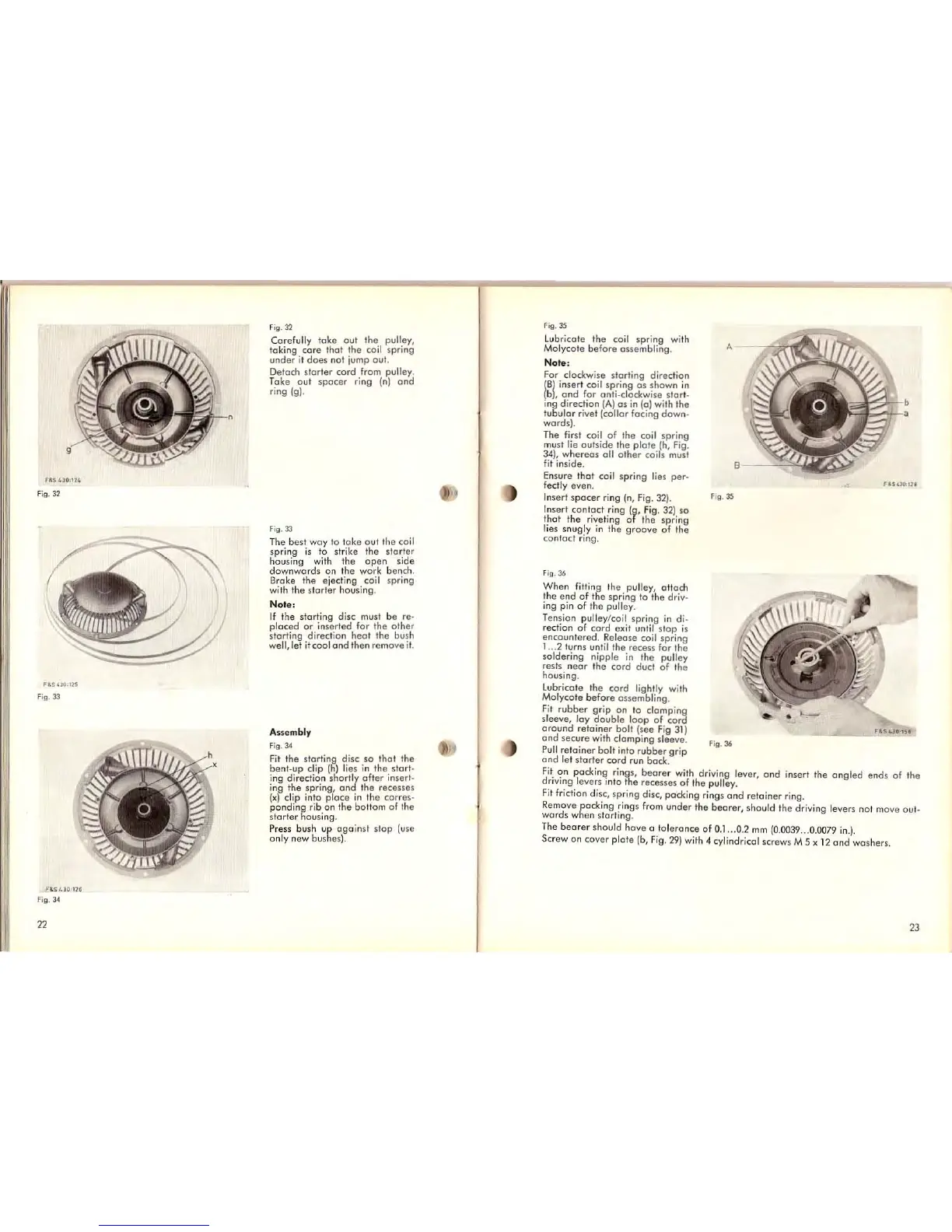

Fig.

35

lubricate

the coil spring with

Molycole b

efore

assembling.

Note

:

For clockw

is

e starting direction

(

B)

insert co

il

spring

as

shown

in

(

b)

,

and

for

an

l

i·

clockwise slort·

ing direction (A)

as

in

(a) wilh the

tubul

ar

rivet (collar facing

dow

n·

wards).

The first coil

of

the coil

sp

ring

must lie

oulside the

plate

(

h,

Fig.

34),

whereas

all

ot

h

er

coils

mu

st

f

it

ins

i

de.

Ensure

tha

t coil spring lies

pe

r·

fectly even.

Insert

spacer

ring

(n,

Fig.

32

).

Insert

contact

ring (g,

Fi

g.

32

)

so

Ihot the riveting

of

the spring

lies snugly

in

th

e gr

oaye

of the

contact ring.

Fig.

36

When

filling the pulley, attach

Ihe end

of

Ihe spring to the driv.

ing pin

of

the pulley.

Tension pulley/coil spring

in

di·

rection of cord exil unlil stop

is

encountered. Release coil spring

1 ... 2 turns until the recess for the

soldering nipple

in

the pulley

rests n

ear

the cord duct

of

the

housing.

lub

ri

cate

the cord l

ig

htly w

it

h

Molycote

before

assemb

ling.

F

it

rubber

grip on

10

cl

amping

sleeve, loy

double

loop

of

cord

around

retain

er

boll (see F

ig

31)

and

secure wilh clamping sleeve.

Pull

retainer bolt into rubber grip

and

lei starter cord run bode.

__

"

__

o.!

f&S

....

."u

Fill

.

36

Fit

on padeing rings,

beore

r with dr

iv

in

g lever, and inserl Ihe

angled

ends

of

the

driving leve

rs

inio the recesses

of

the pulley.

Fit

friction disc,

sp

ring disc, podeing rings

and

re

la

iner ring.

Remove packing rings from u

nder

th

e

bearer,

should the d

ri

ving levers not move out-

wards when sl

ar

ling.

The

bearer

should

have

a tolerance of

0.1

.. . 0.2

mm

(0.0039

... 0.0079 in.).

Screw on cover plate

(b,

Fi

g.

29)

with 4 cyl indrical screws M 5 x

12

and

was

her

s.

23

Loading...

Loading...