6101

6101

6101

6101 Belt

Belt

Belt

Belt Scale

Scale

Scale

Scale Integrator

Integrator

Integrator

Integrator Operating

Operating

Operating

Operating and

and

and

and Service

Service

Service

Service Manual

Manual

Manual

Manual

42

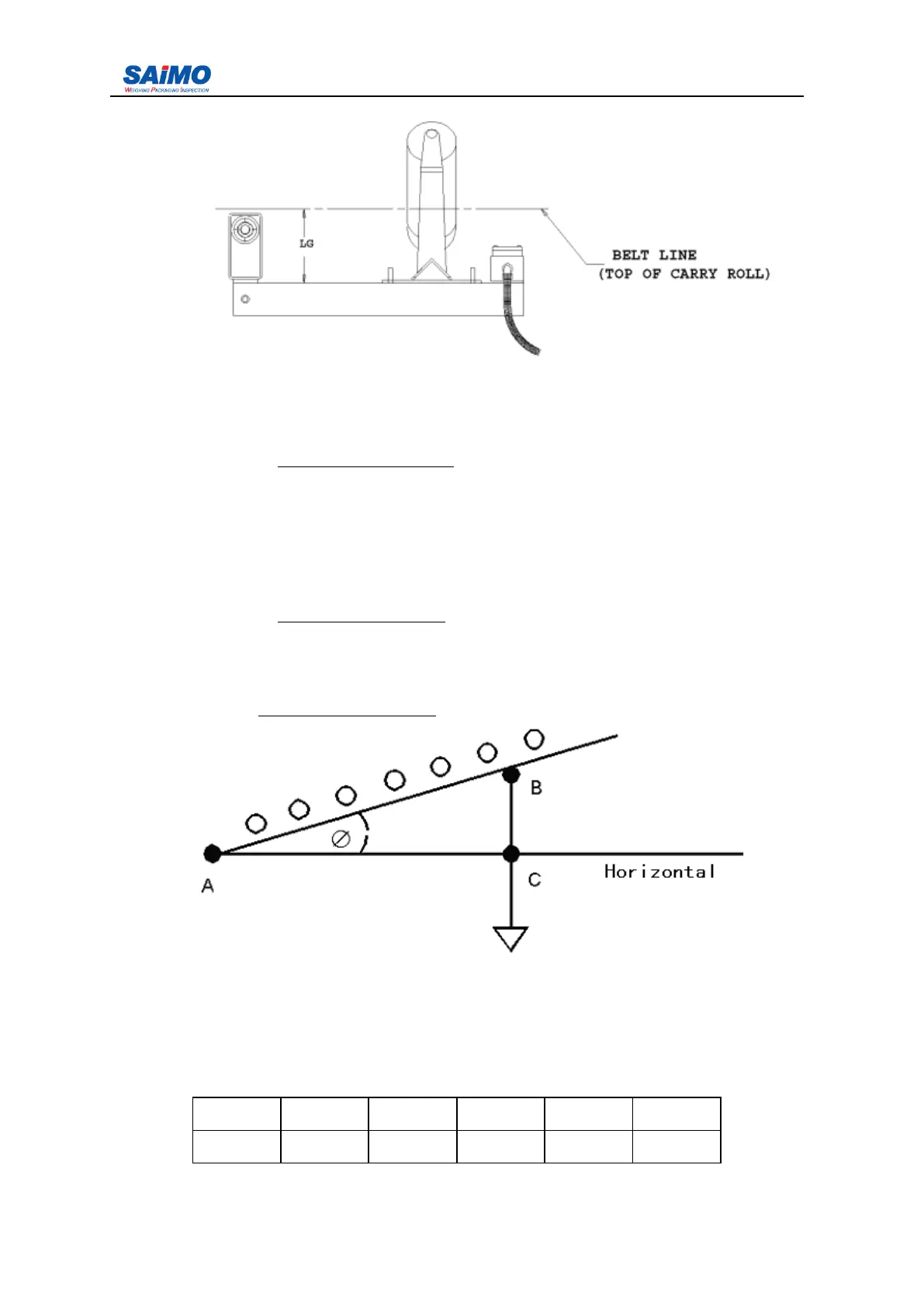

Figure 3- 10 Pulley to scale carriage height

j 、 Load cell No.

Input load cell no. (for example : 1)

( Load cell No. )

k 、 idler spacing — LD

Measure the distance of idler centerline between right side and left side of conveyor. Add up

all the measurements and get the total divided by times measured, then it is average idler

space between right side and left side.

Note: if average idler space is not to the nearest 1mm, it proves installation incorrect. Refer

to belt scale installation manual.

mm ( idler space LD )

l 、 Conveyor

’

s

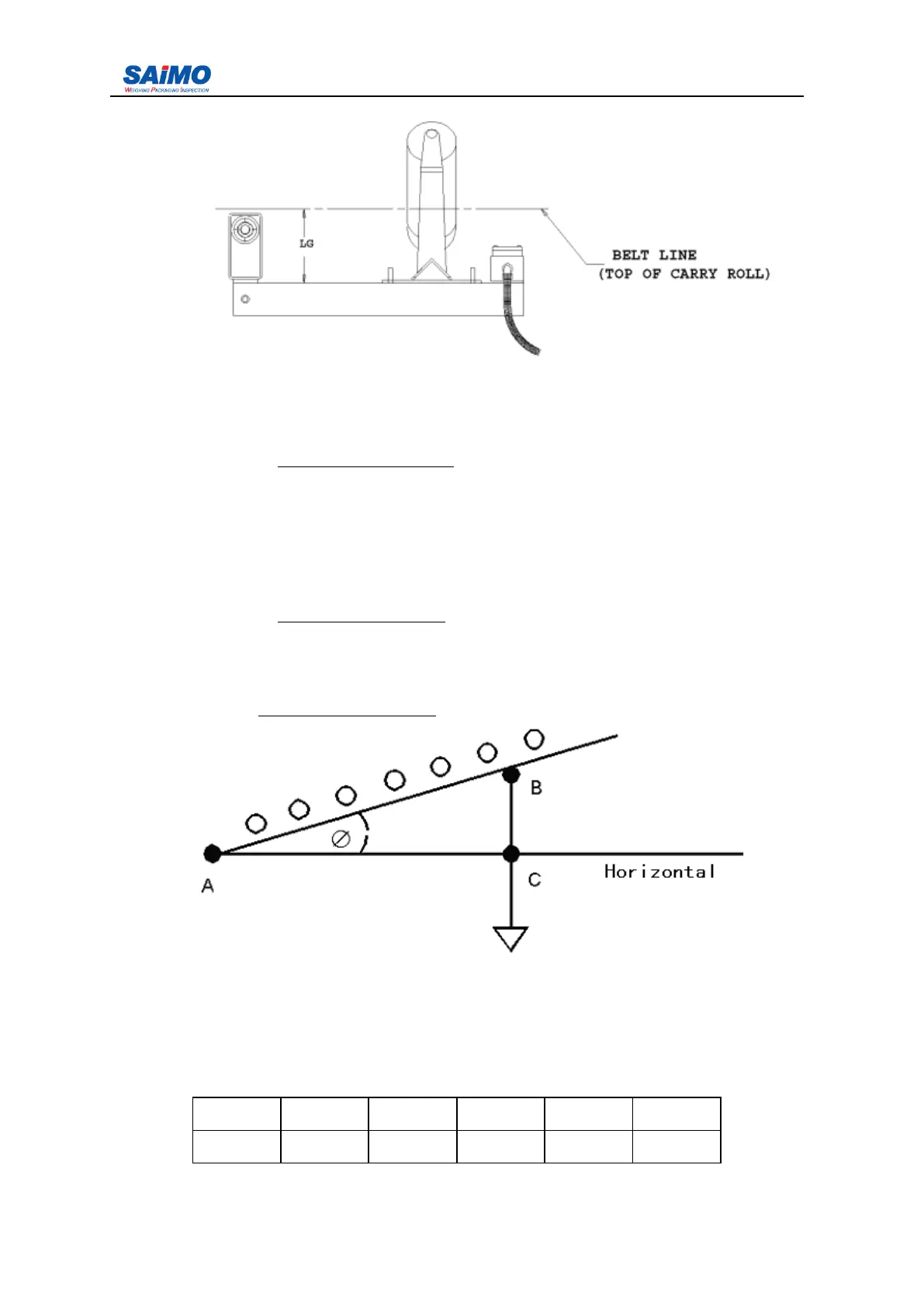

angle of incline ( figure 3 — 11 )

Conveyor

’

s

angle of incline is to the nearest 0.1 degree. Record below: ( example:16.0 ) 。 see

figure 3 — 11

degree ( conveyor

’

s

angle of incline )

Figure 3- 11 Conveyor

’

s

angle of incline

φ

φ

φ

φ =angle

=angle

=angle

=angle of

of

of

of incline

incline

incline

incline

COS

COS

COS

COS φ

φ

φ

φ =

=

=

= ACdistance/AB

ACdistance/AB

ACdistance/AB

ACdistance/AB distance

distance

distance

distance

Choose a convenient distance “ AB ” and measure it in mm. hange a plumb line from B.

measure the horizontal distance from A to plumb line in mm (AC), divide AC by AB to get

COS φ , use the following table:

A ngle φ COS φ A ngle φ COS φ A ngle φ COS φ

0 1.0000 6 .9945 12 .9781

Loading...

Loading...