OPERATING INSTRUCTIONS

4.12 Revised 3/30/2010

End of Operation

This section explains the operating procedure to be

carried out after the system operation has ended.

1. Press the “” side of the power switch to turn off the

power.

2. Open the unloading door and check if any processed

receiving rack remains. Remove all such racks, if any,

and close the unloading door.

3. Open the unloading station access door, grab the

handle, and pull out the unloading station receiver.

Place the lid on the unloading station, push the

unloading station receiver back into the system, and

close the unloading station access door.

NOTE: Performing periodic cleaning and maintenance of

the system during the above end-of-operation processing

allows the system to operate in good condition for an

extended period of time.

What to Do before Prolonged Period of

Non-operation

If the system will not be used for a prolonged period

(one week or more), follow the steps below:

1. Turn off the power switch.

2. Disconnect the system power plug from the power

outlet.

3. Open the cover. Remove the cover glass holders and

store them in a dry place.

CAUTION: If the cover glass holders are stored in a

humid place, they may cause problems, such as

allowing two slides to be picked up together, the next

time the holders are used.

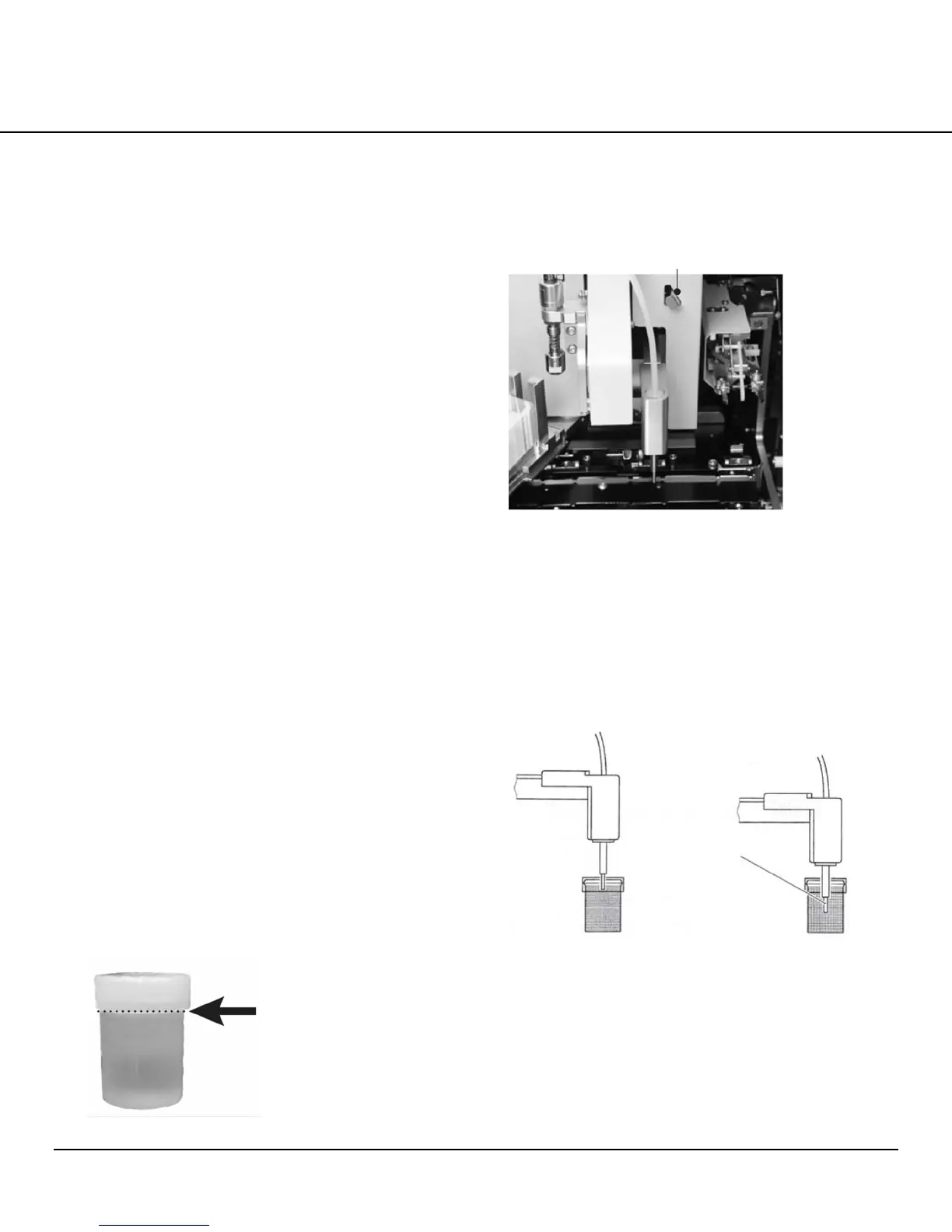

4. Add solvent to the anti-drying bottle (Figure 4-T).

Figure 4-T

5. Push the lever down to the left (Figure 4-U). The

dispensing nozzle comes down and its tip dips into

the liquid in the anti-drying bottle (Figure 4-V).

Figure 4-U

6. To prevent mounting medium in the dispense tubing

from solidifying, confirm that a mounting medium

bottle is placed.

7. Check if a sufficient amount of solvent in the anti-

drying bottle.

8. Clean the interior of the system.

9. Close the cover.

Figure 4-V

Fill solvent until this

line just below the lid.

The tip drops

deeper into

the liquid.

Normal state Dispensing nozzle down

lever is pulled

Dispensing nozzle down lever

Loading...

Loading...