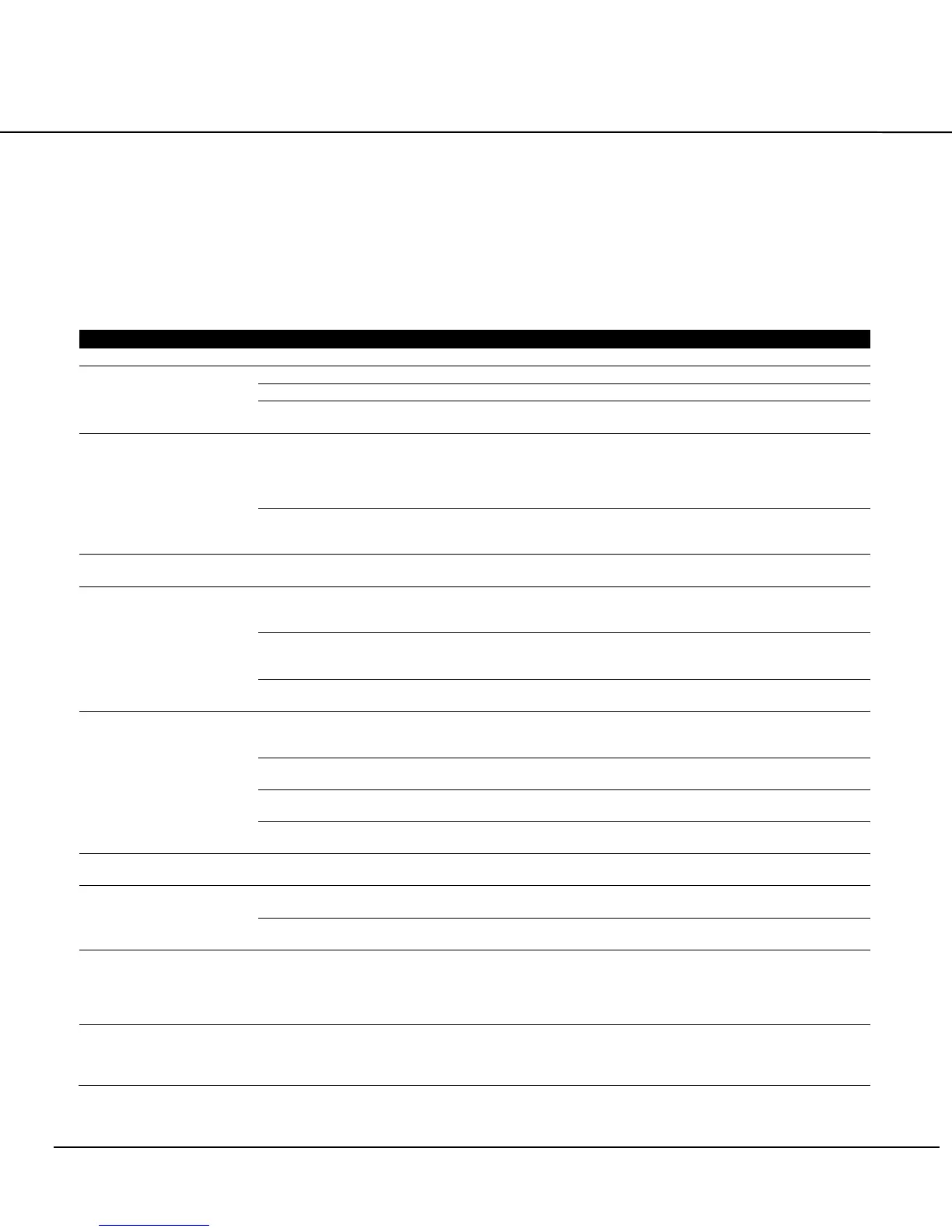

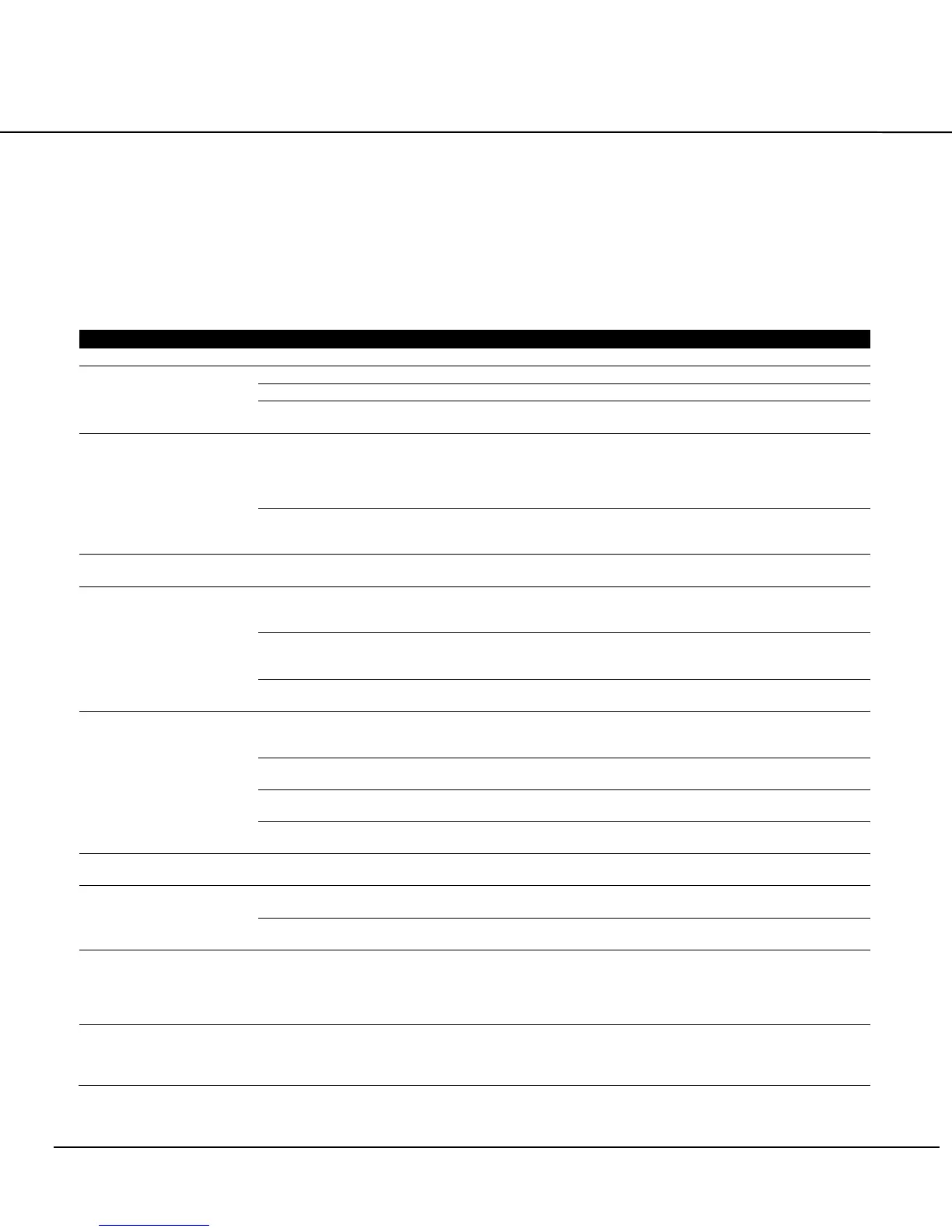

TROUBLESHOOTING

6.2 Revised 3/30/2010

Troubleshooting Table

Check the possible problem conditions listed in the table

below and if any of them applies to the problem that has

occurred, take the specified action or actions. If the problem

persists or when none of the listed conditions applies, contact

the Sakura dealer.

The power is not turned on.

The power plug is disconnected.

The power is not supplied.

Check the breaker on the facility side.

The system power was cut off temporarily

(= momentary power failure).

Turn off the system power and then turn it back on.

The mounting medium bottle is empty.

Replace the mounting medium bottle or add mounting

medium to the specified level or more. If the mounting-

medium level detection function is not working, the

equipment must be adjusted. Contact the Customer

Service Center or the Sakura distributor.

Mounting medium at the tip of the dispensing

Dissolve the solidified mounting medium using solvent

(usually xylene). For details, consult the Customer

Service Center or the Sakura distributor.

The system suddenly stopped

operating.

Take a remedial action according to “Actions to Be Taken

upon Power Outage during Operation” in Section 4.

taken out or they dropped

The suction pads on the cover glass arm have

deteriorated or are damaged.

Replace the suction pads on the cover glass arm with

new ones. Contact the Customer Service Center or the

Cover glasses are not stored in an appropriate

environment.

Store cover glasses in a place not subject to high

humidity. If stored in a humid place, cover glasses may

Old cover glasses were used.

Use new cover glasses. Old cover glasses may stick

Two or more cover glasses

are coverslipped together.

Cover glasses are not stored in an appropriate

Store cover glasses in a place not subject to high

humidity. If stored in a humid place, cover glasses may

Old cover glasses were used.

Use new cover glasses.

Old cover glasses may stick together easily.

The type of cover glasses used or the angle by

which the cover glass is lifted is not appropriate.

Increase the cover glass lifting angle.

Cover glasses used are not specified for automatic

coverslippers.

Use cover glasses specified for automatic coverslippers.

Cover glasses get cracked. The type of cover glasses used or the angle by

which the cover glass is lifted is not appropriate.

Decrease the cover glass lifting angle.

An empty receiving rack is not

picked up.

The receiving rack is not set in the specified

position correctly.

Set the receiving rack properly in the concaved part of

the unloading area.

The receiving rack is damaged.

Contact the Customer Service Center or the Sakura

distributor.

The processing capacity drops

and every other slide is

skipped. (The CG size on the

screen is blinking.)

The cover-glass level detection function was

actuated, and the system switched to the slide

pickup mode only after a cover glass was

detected.

Press the STOP key and add cover glasses, and the

original processing capacity should be restored. If

coverslipping is continued without taking the above

action, the cover glass count will drop to 0 and a “No

cover glass” error will generate.

A receiving rack containing

coverslipped slides remains

during operation, but “OK” is

not displayed on the screen.

When the unloading door was opened, not all

receiving racks whose drying time had elapsed (for

which “OK” was lit) were taken out.

Open the unloading door, take out all receiving racks

containing coverslipped slides and whose drying time

has elapsed, and then close the unloading door.

Loading...

Loading...