35

The range of floatation wheels available for SAM sprayers is vast. SAM would not advocate using pressures

in any floatation wheel below 1 Bar (15 psi). The ultra low pressures of bygone years have proved to be of no

particular advantage to the soil or the crops. It simply caused the tyres to wear rapidly and increased fuel

consumption.

Consult SAM Ltd for further information.

Floatation wheels impose extremely high stresses on all associated components i.e. bearings, axles,

kingpins and steering components. A shorter life expectancy on these wearing parts must therefore be

expected, especially in the case of bushes.

Any help the operator can give the machine in reducing the stresses caused by floatation wheels: - by not

driving on kerbs; by not driving at excessive speeds on ploughed land; by not using excessive acceleration or

braking, will extend components' life substantially.

Warranty on component failure, associated with floatation wheels, is severely limited and will only be

accepted for a manufacturing defect.

TYRES - FLOATATION

3-4

The tyres on a crop sprayer are probably the most abused item on the machine. Because of the 'ever

decreasing weight' nature of a crop sprayer, the tyres attract a loading bonus, however, this bonus refers to

low speed operations only.

Ensure tyre size i.e. contact area, is suitable for the prevailing conditions. Narrow tyres, very steep slopes

and green foliage just DO NOT MIX.

High loads and high speeds can cause premature tyre wear not only to the tyre tread but also within the tyre

carcass.

Wheel rims and/or centers will also fracture under excess fatigue (i.e. under the above conditions).

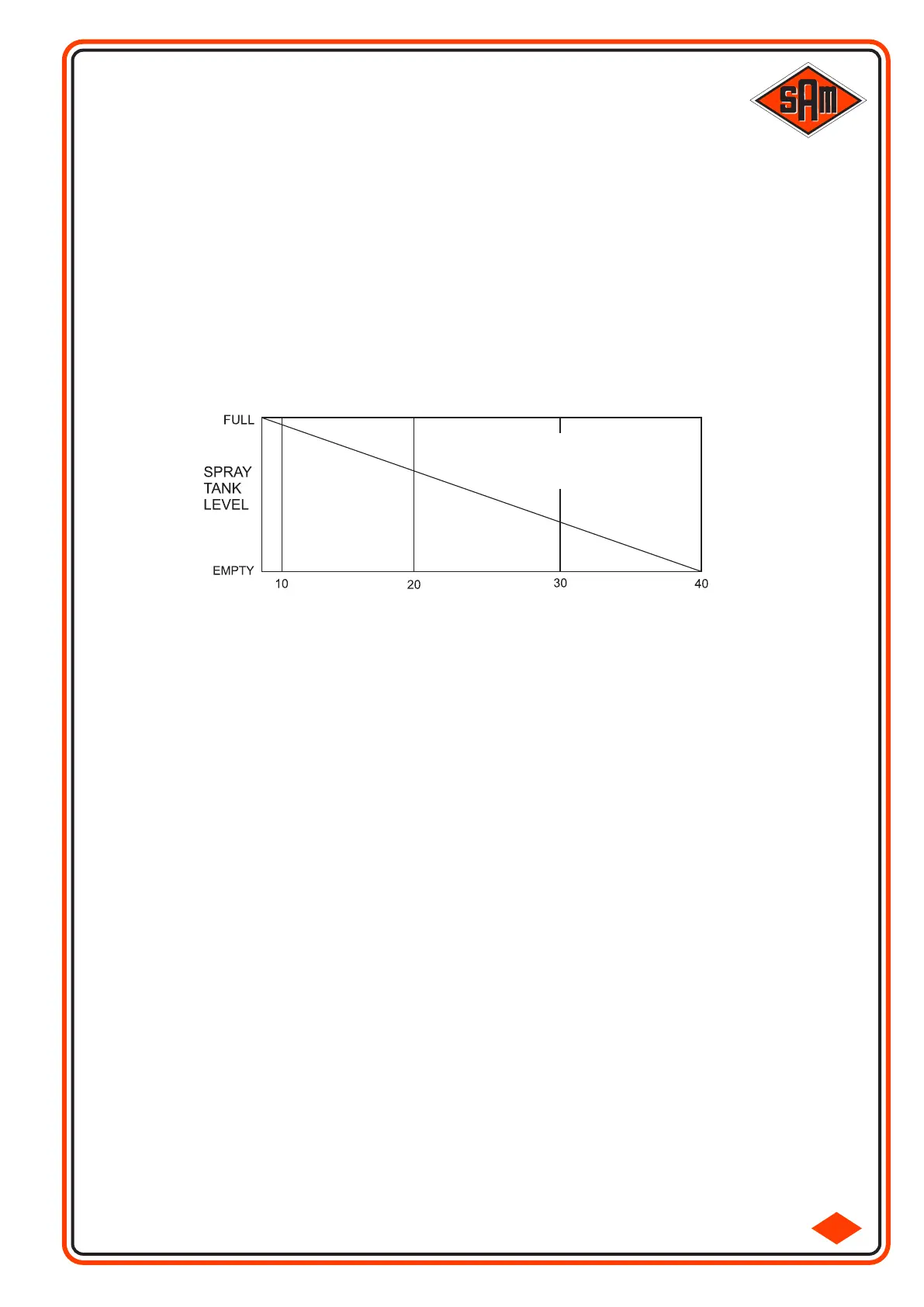

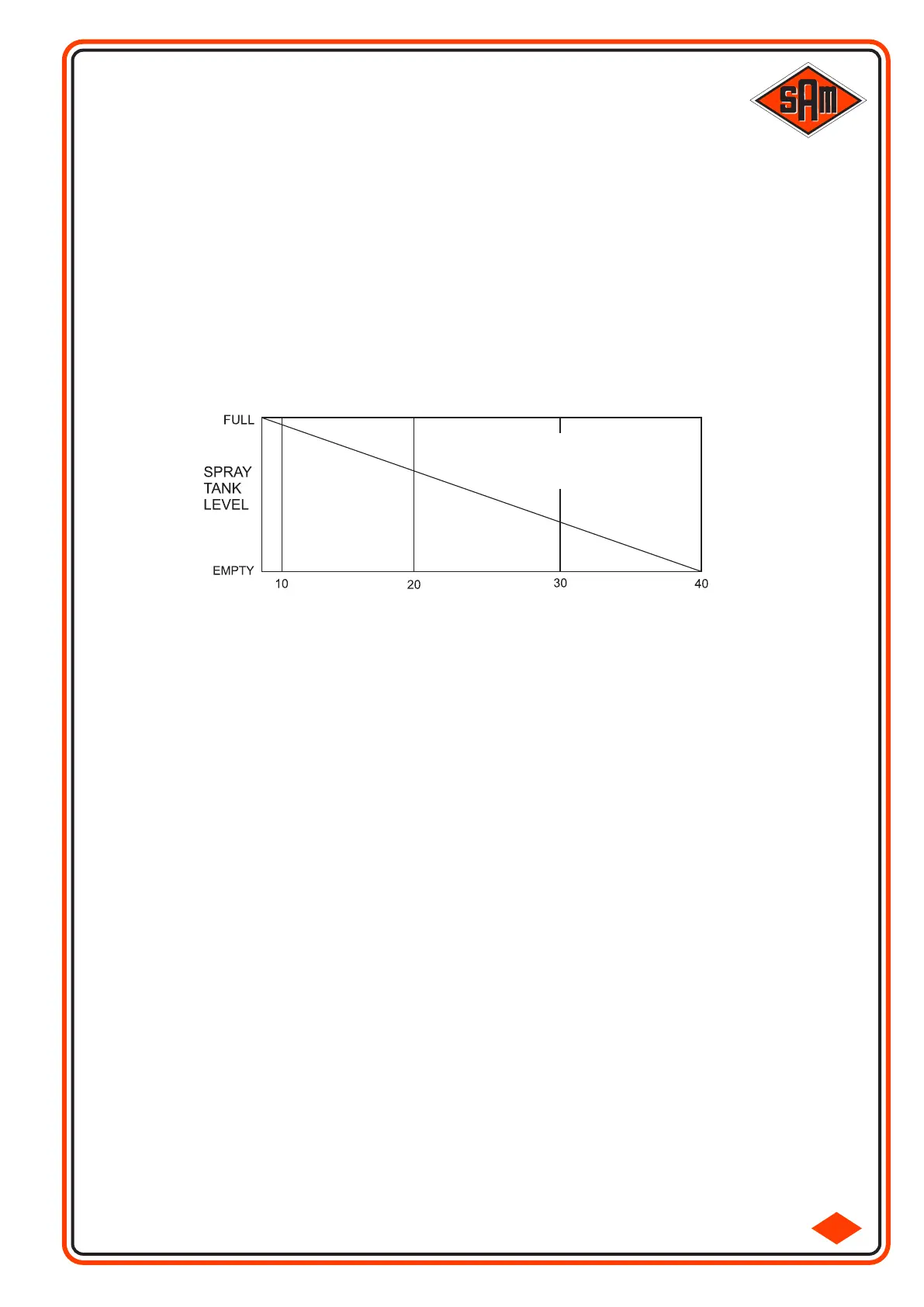

Your attention is therefore drawn to the load/speed graph below.

TYRES - GENERAL

It should be noted that an unusual tyre wear pattern has been identified on sprayers that spend a large amount

of time fully laden on the road. One or more tyres will show very heavy wear between the center of the tyre and

the outside edge but without the feathered edge normally associated with tracking problems. The cause of

this phenomenon is the tyre rolling under the rim during cornering. Whilst the wear rate can never be reduced

(see load/speed graph), it can be spread more evenly across the tyre by increasing the tyre pressure by

approximately 10 psi.

SPEED (KM/H)

Rapid Tyre Wear

High Rim Fatigue Rate

Loading...

Loading...