5 Troubleshooting

10 EB 3132-2 EN

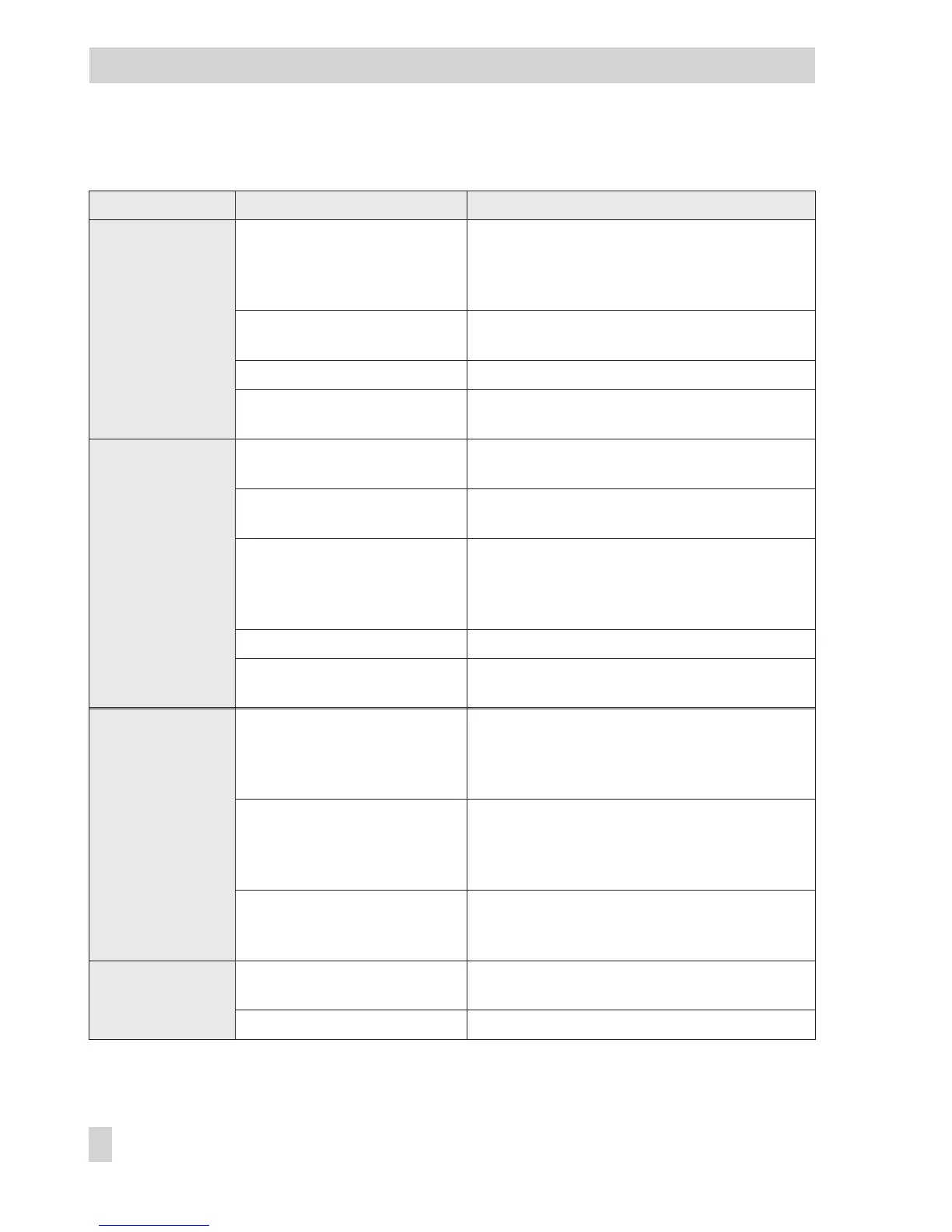

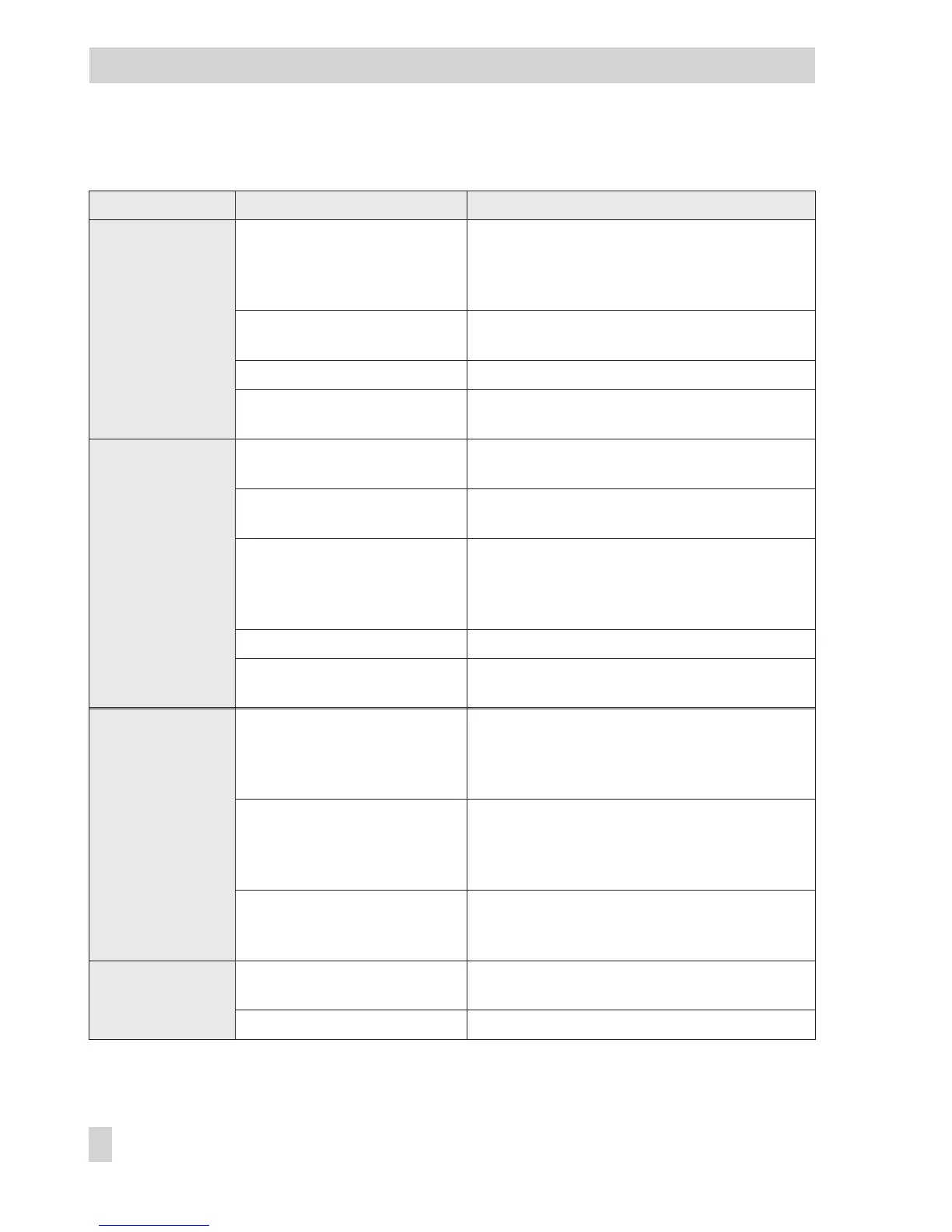

Troubleshooting

Fault Possible cause Solution

Flow rate Leakage between seat and plug Remove the regulator from the pipeline. Clean

the seat and plug. If necessary, replace the plug

(section 4.1). Otherwise, return the regulator to

SAMSON for repair.

Flow rate set point

exceeded

Operating diaphragm defective Replace the diaphragm (section 4.2) or return

the regulator to SAMSON for repair.

Control line clogged Remove the control line and clean it.

Valve too large for control task Recalculate the K

VS

coefficient and contact

SAMSON.

Flow rate set point

not reached

Set point range incorrectly

selected

Check the set point range and contact

SAMSON.

Safety device (e.g. pressure

limiter) triggered

Check the plant. Unlock the safety device.

Insufficient differential pressure

across the plant

Compare the existing differential pressure across

the plant with the plant drag.

Min. differential pressure = differential pressure

at restriction + (

V

•

/K

VS

)²

Strainer clogged Drain the strainer's filter and clean it.

Valve incorrectly installed Install the regulator with the direction of flow

matching the arrow on the valve body.

Temperature Leakage between seat and plug Remove the regulator from the pipeline. Clean

the seat and plug. If necessary, replace the plug

(section 4.1). Otherwise, return the regulator to

SAMSON for repair.

Temperature set

point at the sensor

exceeded or not

reached

Sensor installed in the wrong

location

Check that the sensor is fully immersed in the

process medium. Check that it is not installed in

a place where idle times or heat accumulation

occur.

Safety device (e.g. safety tem

-

perature limiter or monitor)

triggered

Check the plant. Unlock the safety device.

Temperature set

point at the sensor

exceeded

Insufficient energy available for

heating or cooling

Draw up an energy balance.

Thermostat defective Return the thermostat to SAMSON for repair.

Loading...

Loading...