EB 8310-6 EN 6-3

Start-up

longer be correct. This may apply, for exam-

ple, to the conguration ID or the symbol af-

ter reversal of the direction of action.

Î Immediately renew any nameplates or

labels with incorrect or outdated infor-

mation.

Î Add any new values to the nameplate. If

necessary, contact SAMSON to obtain a

new nameplate.

Risk of actuator damage due to excessively

high or low tightening torques.

Observe the specied torques on tightening

actuator components. Excessively tightened

torques lead to parts wearing out quicker.

Parts that are not tightened far enough may

loosen.

Î Observe the specied tightening torques

(uAB0100).

Risk of actuator damage due to the use of

unsuitable tools.

Î Only use tools approved by SAMSON

(uAB0100).

6.1 Preloading the springs

Refer to Fig.6-1

By preloading the springs in the actuator, the

following can be achieved:

− The thrust is increased (only actuators

with "stem extends")

NOTICE

NOTICE

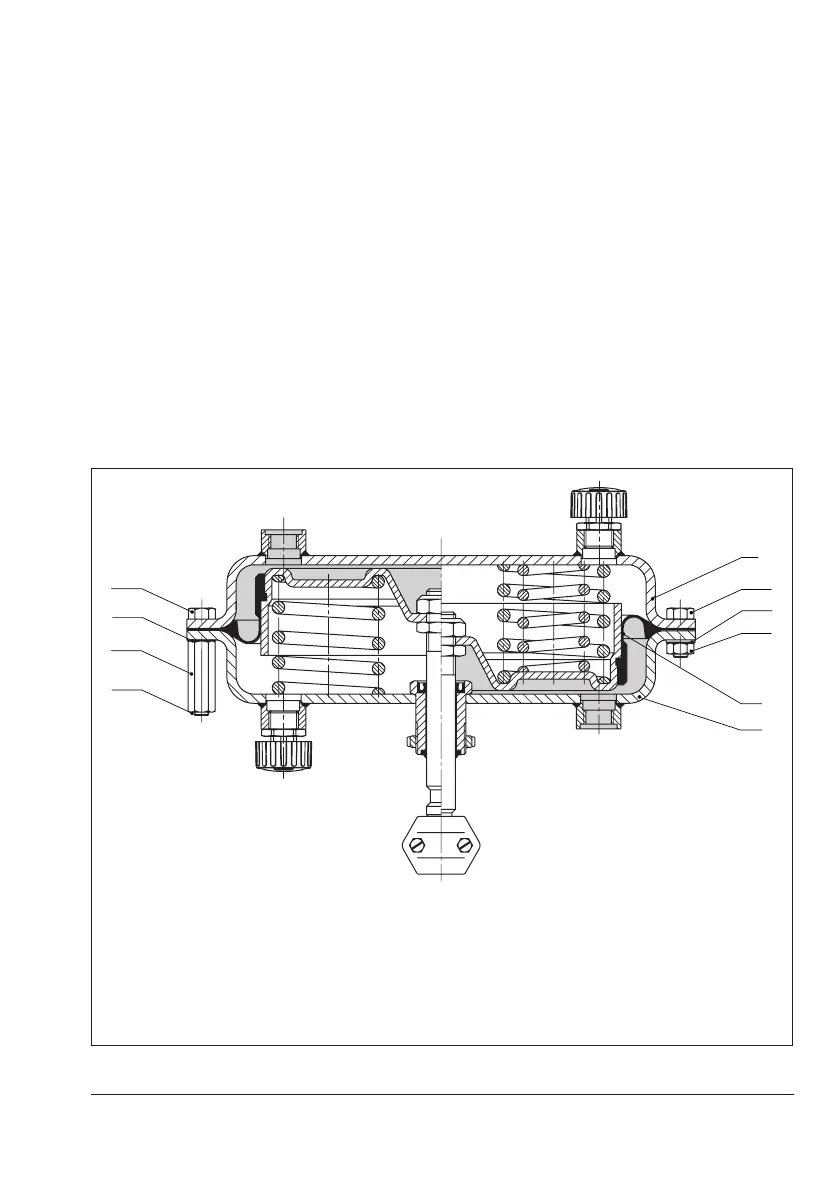

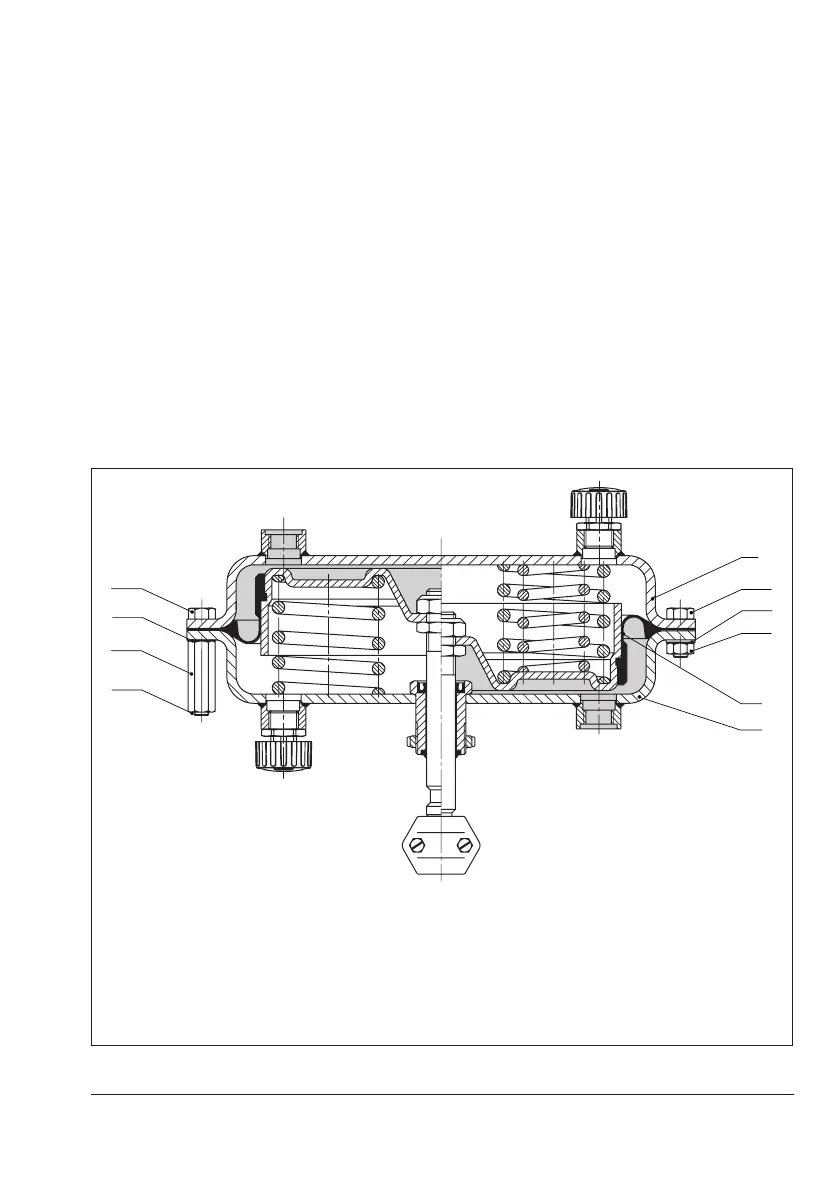

A1 Top diaphragm case

A2 Bottom diaphragm case

A4 Diaphragm

A20 Hex bolt

A21 Hex nut

A22 Hex bolt (preloading)

A23 Hex nut (preloading)

A24 Blanking plug

A25 Shim

A25

A24

A20

A25

A21

A1

A2

A4

Fig.6-1: Actuator with clamping nuts and bolts

5. Screw the short nuts (A21) with shims

(A25) onto the bolts (A20). Observe

tightening torques.

6.1.2 Increasing the actuator

thrust

The thrust can only be increased in actuators

with "stem extends" direction of action. To

achieve this, the springs of the actuators can

be preloaded by up to 12.5% (240cm²) or

by up to 25% (350 and 700cm²) of their

travel or bench range.

Example: Preloading is required for a bench

range of 0.4 to 2bar. 25% of this span is

0.4bar. Therefore, the signal pressure range

is shifted by 0.4bar to 0.8 to 2.4bar. The

new lower signal range value is 0.8bar and

the new upper signal range value 2.4bar.

Î Write the new signal pressure range of

0.8 to 2.4bar on the actuator nameplate

as the operating range with preloaded

springs.

Loading...

Loading...