Installation Instructions

Ambient Conditions

Choose a suitable location for setting up the machine/system.

The place of installation should be dry, level and even. The allowable operating tempera-

ture range is -10°C to +40°C (14°F to 104°F).

Observe the following when choosing a location for the equipment:

– Avoid extreme heat radiation from heaters or direct sunlight

– Protect the equipment from excessive vibrations (e.g., from a conveyor line in close

proximity to the system)

– Make sure the equipment is easily accessible for maintenance and repair work

– Avoid exposure to drafts; e.g., from opened doors or windows,

or from air conditioning systems

– Do not set up the equipment on a soft, loosely packed or springy surface

Floor Load Limits

The load-bearing capacity at the place of installation must be sufficient for the

machine/system.

Transport to the Place of Installation

Caution:

Do not hold the machine/system by the conveyor belt to lift or move the equipment.

When transporting the equipment, make sure the checkweigher is lifted only by the beams

on the base frame.

Models WM60..., WM120... and WM35LFP... must be secured for transport using overload

stops (screws).

Setting Up and Installing the Equipment

You can use a transport vehicle such as a forklift or elevating platform truck to position

the machine/system at the place of installation. Observe the conditions listed under

“Safety Instructions regarding the Place of Installation” above. Special training is not

required for installing and commissioning the equipment. All installation work should be

performed by technicians. The steps for installation and commissioning are described in

the order in which they are to be performed.

Caution:

Work on the electrical parts inside the machine/system must be performed by a trained

electrician, or a person with appropriate training working under the direct supervision

of a trained electrician, and must be carried out in accordance with the applicable rules

and regulations pertaining to electrical equipment.

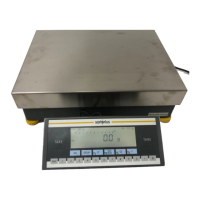

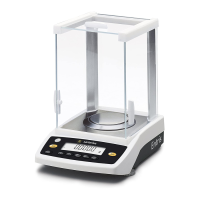

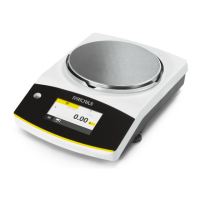

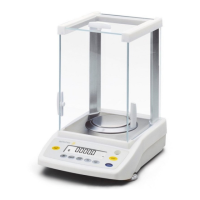

Handling of the Weighing Platform and Conveyor Belt

The weighing platform is a high-precision measuring instrument. For this reason,

the following must be observed when handling or using the weighing platform:

Do not expose the weighing platform unnecessarily to extreme temperatures, moisture,

shocks, or vibration, which could result in damage. The weighing instrument must not be

moved by force applied through the conveyor belt on the weighing platform.

Visual Inspection

As soon as the equipment is delivered, inspect it for visible signs of any damage that may

have occurred during transport.

Important Note:

The attachment of the weighing platform to the base frame is adjusted at the factory. The

fastening screws are secured with locknuts. Level the instrument by adjusting the leveling

feet on the base frame and referring to the built-in level indicator.

If the equipment was delivered without a base frame, grasp the frame to lift the equip-

ment.

Transport to the Place of Installation

Caution:

Do not lift the equipment by the conveyor belt. Use only the suspension points indicated

(see illustration) for transport.

Note:

If the weighing platform is to be replaced, make sure the weighing platform frame is not

bent out of alignment. Position the spacing plates before bolting the equipment together.

6

Loading...

Loading...