Changing the Conveyor Direction

You can change the direction of conveyance by turning the entire checkweigher around

(i.e., the checkweigher with frame; models WM35, 60 and 120).

Only one direction of conveyance is possible for checkweigher model WM6.

§ Install the checkweigher without its support trestle to have it facing in the desired direc-

tion. If the checkweigher has a support trestle, remove the 4 screws that attach the trestle

to the frame.

§ Separate the connection between photo sensors and control cabinet. Connect the photo

sensor cable in the control cabinet in accordance with the numbering.

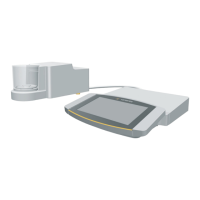

§ Install the display and control unit (with column) on the other side of the checkweigher,

in accordance with the operating instructions.

Important Note:

Do not rotate the weighing platform by 180°.

§ Turn the checkweigher with its frame and re-fasten the photo sensor cable in according

with the numbering.

Overload Stops

Note:

The load receptors on models WM60..., WM120... and WM35LFP... are secured

by 4 overload stops (screws).

§ Following installation of the equipment and before commissioning, remove these over-

load stops as follows:

§ Remove the cover plate (SW 13 or 19).

§ Use the enclosed metal strip (thickness: 0.3 mm) to distance the load receptors by 0.3

mm.

Note:

The metal strip is shipped in a polyethylene bag inside the control cabinet.

§ Use the locknut to secure the setting.

§ Replace the cover plate and fasten with the screws.

Caution:

Always secure the load receptor on these models with the overload stops before

transporting the equipment.

!

8

Loading...

Loading...