General system description 2 - 5

Doc.nr : Rc400-Manuale_v20_e.doc

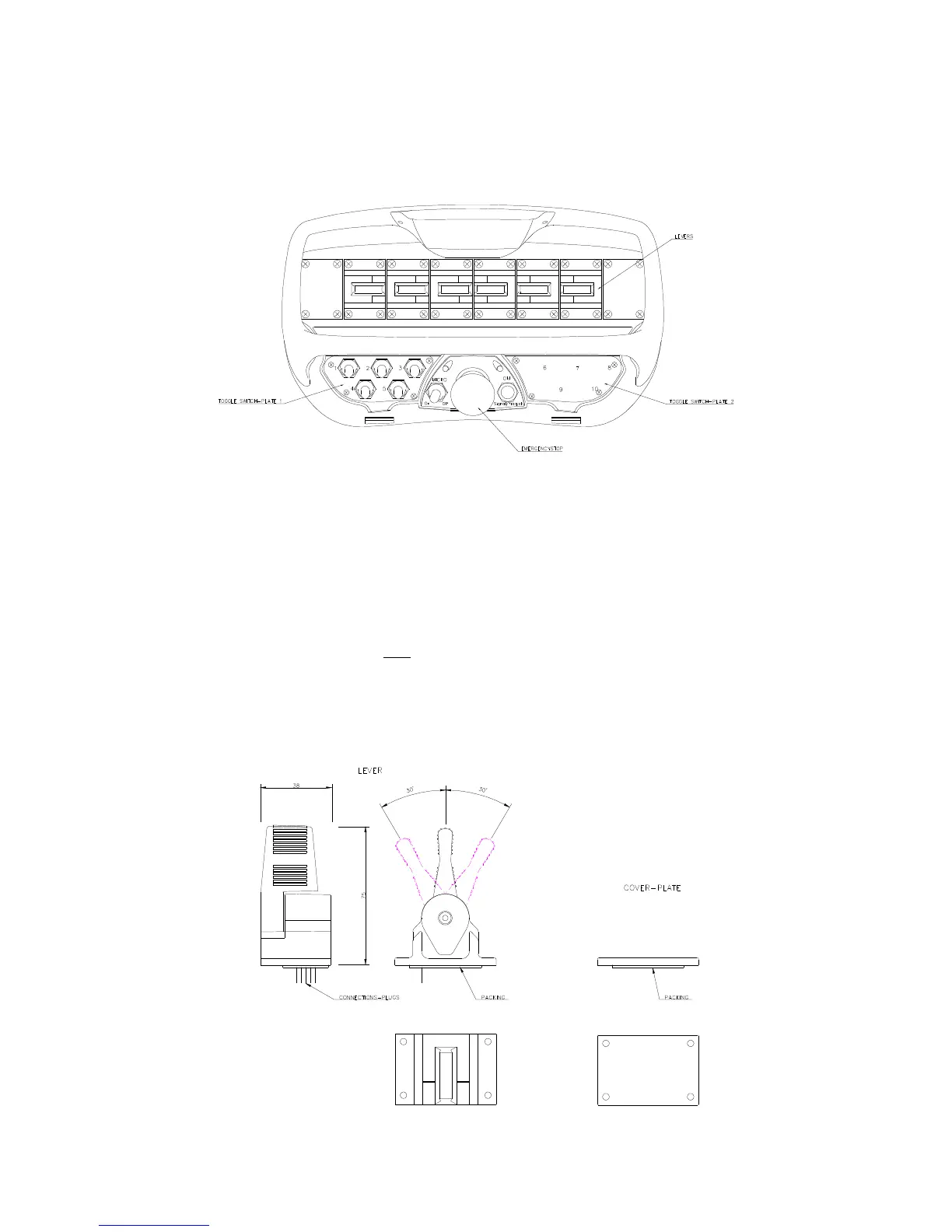

A brief description is given now of the component parts of the control unit.

The control unit is comprised of manouevre levers for proportional control, switches for

ON/OFF and function changing, micro-operation and emergency stop. ( See separate headings

below ).

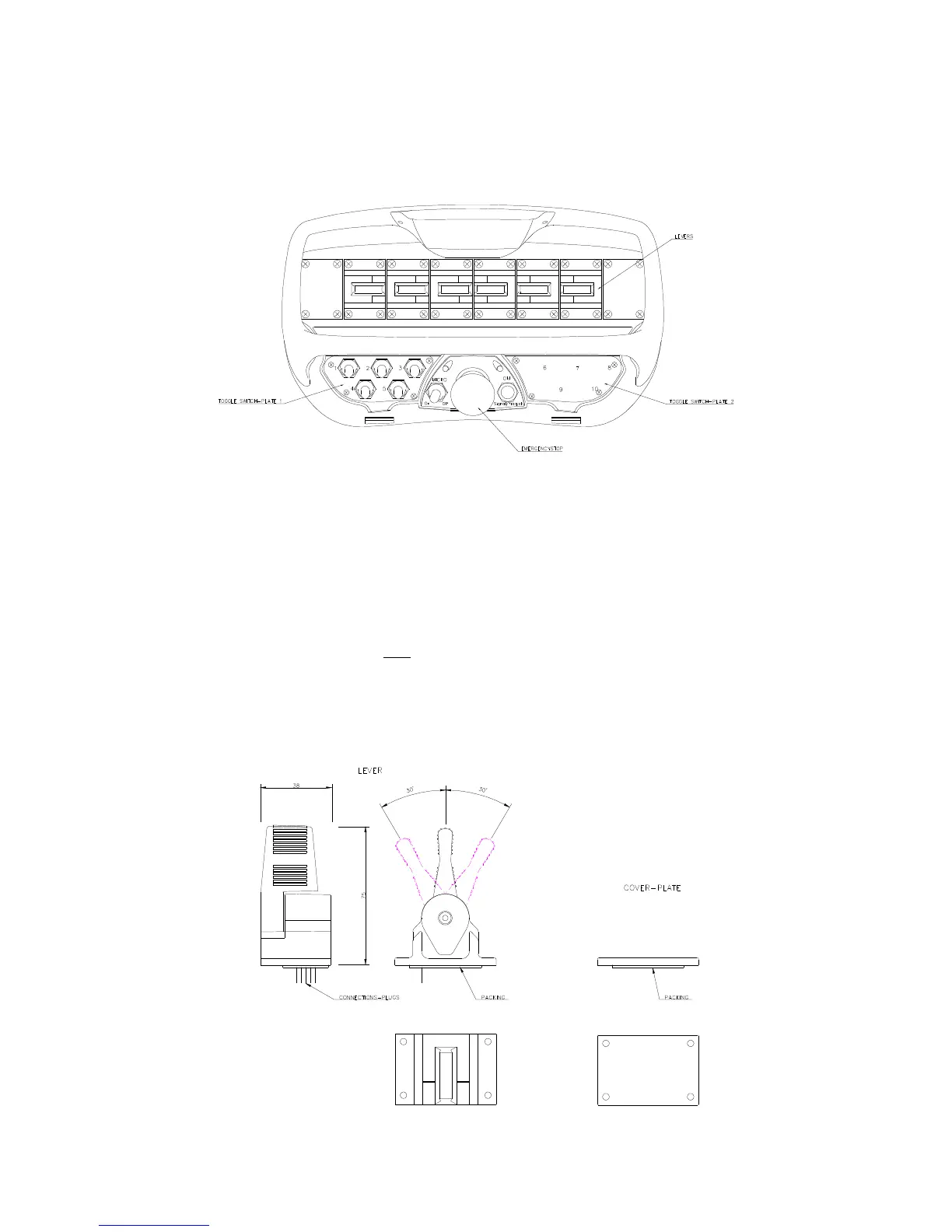

Manoeuvre levers.

The manoeuvre levers give fully variable proportional operation and are sprung loaded to

return to zero position, i.e. "dead-man's-handle". When the manoeuvre levers are moved from

zero position the respective hydraulic function starts to operate slowly and increases in speed

as the lever is moved further from zero position and vice versa as the lever is moved back

towards zero position. If any levers are not included for a particular installation, a cover plate

can be mounted for the unused lever locations.

( See also title " Micro-speed control " ).

For safety reasons all manoeuvre levers must be in their zero/neutral positions for a start-up to be made. If any

lever is not in its zero / neutral position during start-up, the control unit will blink and beep the same number of

times as the number of the lever to indicate which manoeuvre lever is faulty. The control unit can be used but the

faulty lever will be locked and disengaged. ( For example if it beeps and blinks five (5) times, it is the 5th lever

from the LEFT which is faulty or giving the problem signal ).

Loading...

Loading...