9

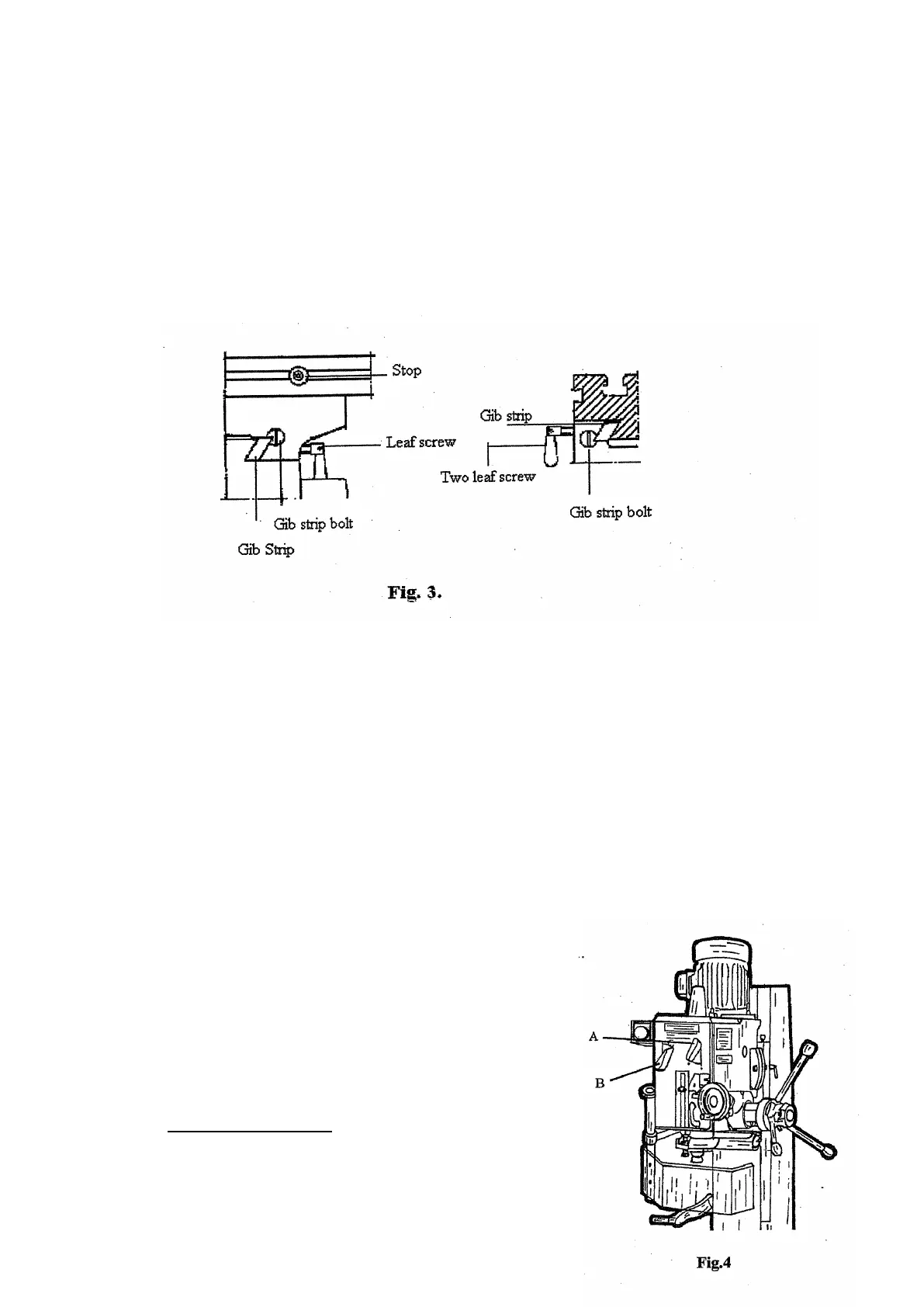

Adjusting Table Slack and Compensate for Wear

1. Your machine is equipped with hub strip adjustment to compensate for wear and

excess slack on cross and longitudinal travel.

2. Clockwise rotate the job strip bolt with a big screw for excess slack otherwise a little

counter clockwise if too tight.

3. Adjust the jib strip bolt until feeling a slight drag when shifting the table.

Clamping, Table Base and Machine Base

1. When milling longitudinal feed, it is advisable to lock the cross feed table travel to

insure the accuracy of your work. To do this, tighten the small leaf screw located on

the right side of the table base.

2. To tighten the longitudinal feed travel of the table for cross feed milling, tighten the two

small leaf screws on the front of the table base.

3. Adjustable travel stops are provided on the front of the table for control of cross travel

and the desired milling length.

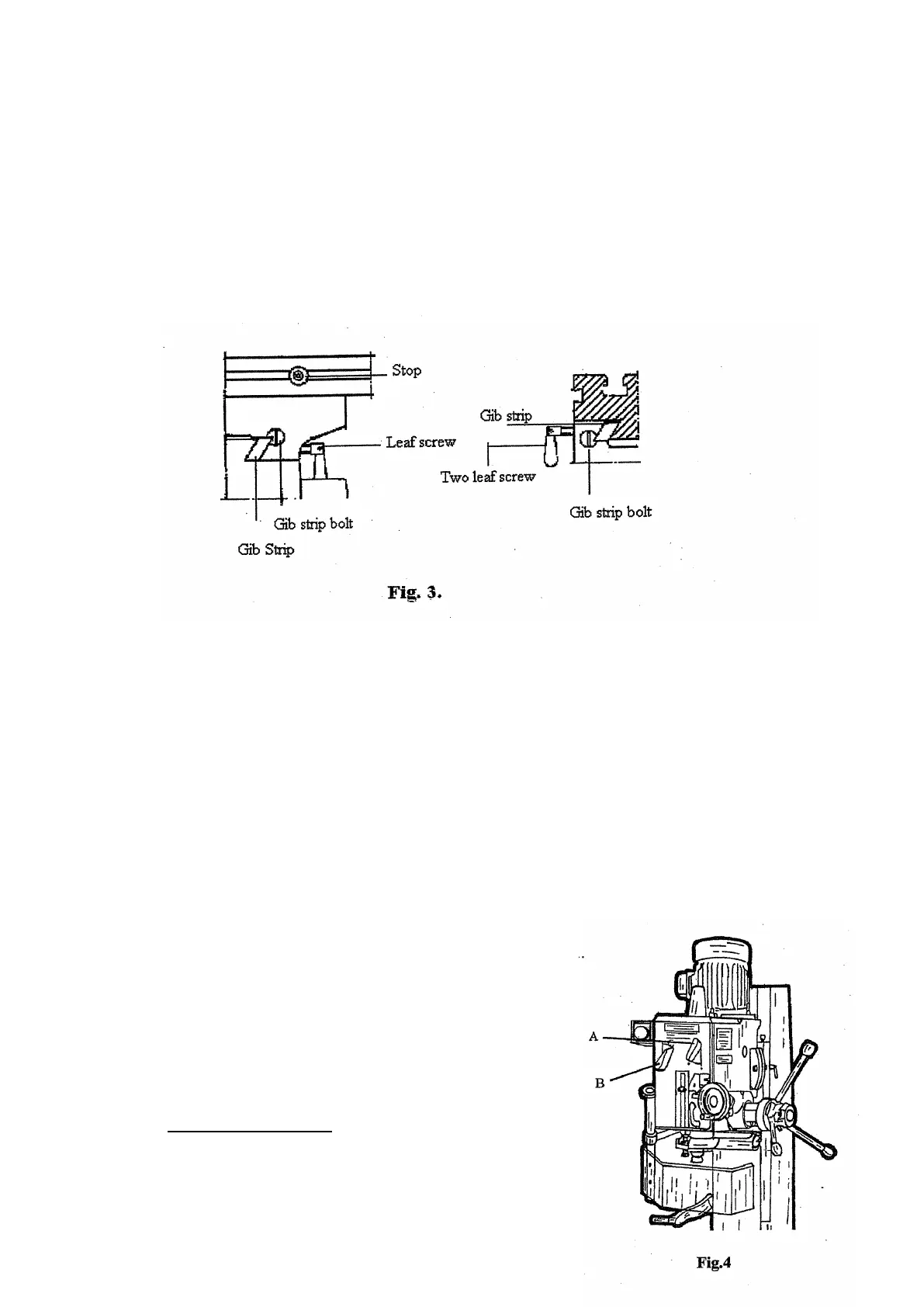

Speed Changing

1. Turn power off

2. Select the suitable RPM from speed

charts of table 1.

3. Turn the speed lever A and B to

correct position.

4. Turn on the power.

Caution for Switch

Loading...

Loading...