www.scheppach.com / service@scheppach.com / +(49)-08223-4002-99 / +(49)-08223-4002-58

GB

|

27

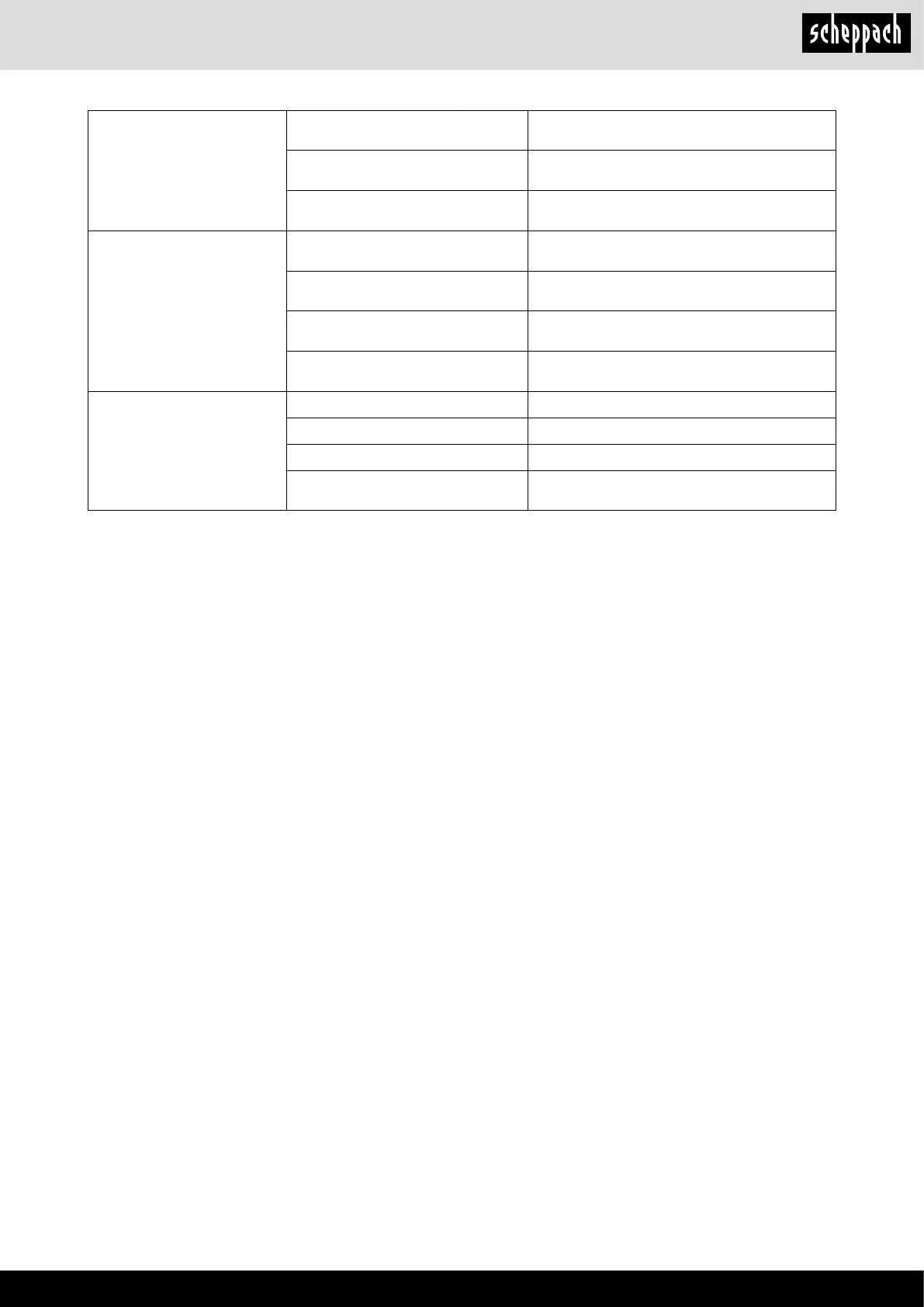

Slag formation on interfaces?

Tool/material creates heat.

Allow the material to cool down and then contin-

ue cutting

Cutting speed too low or current too

high.

Increase the speed and/or reduce the current un-

til the slag has been reduced to a minimum.

Plasma burner component parts are

worn

Check and replace worn parts.

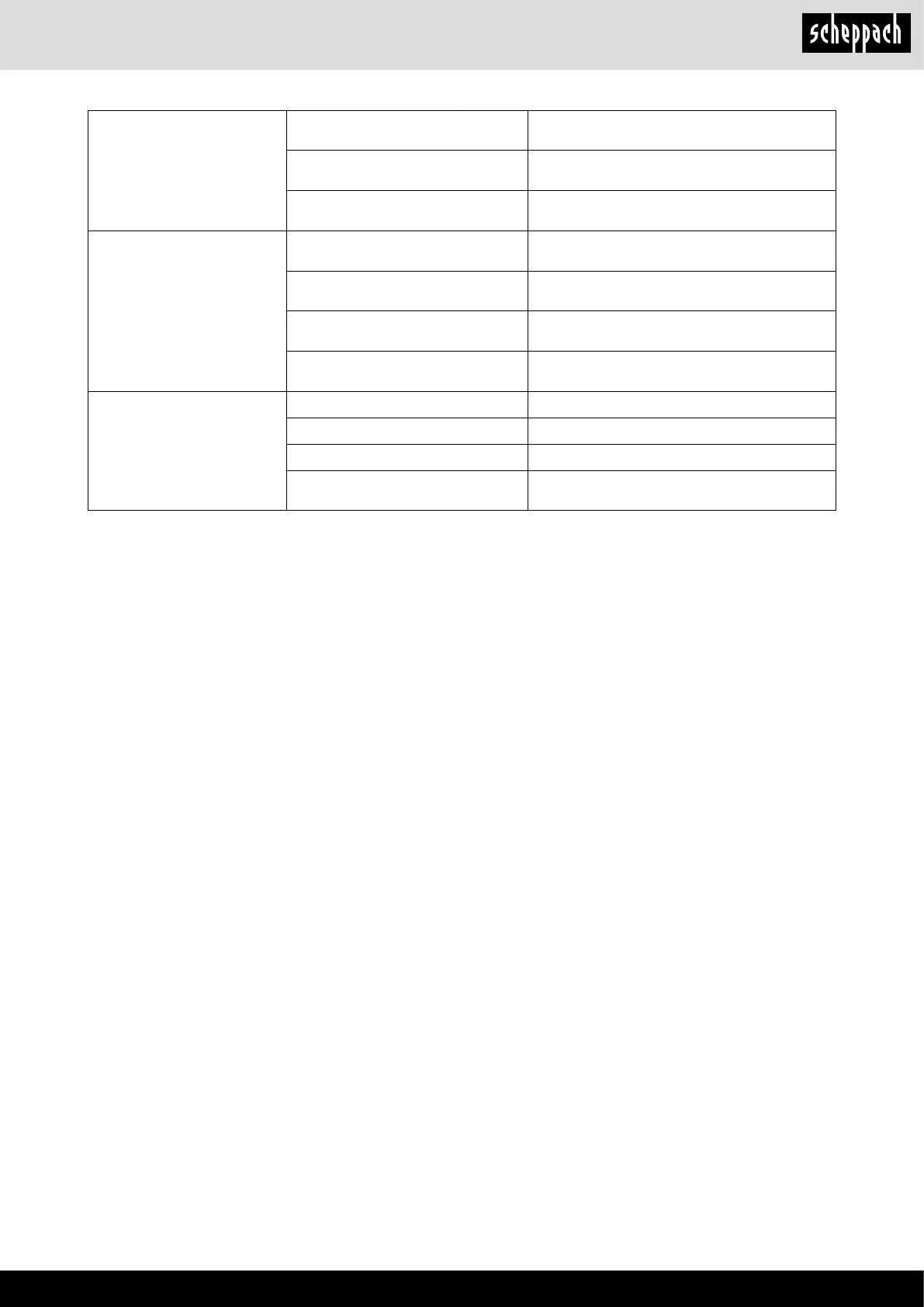

Arc stops during cutting?

Cutting speed too low.

Increase the cutting speed until the problem no

longer exists.

Plasma burner is held too high and

too far away from the material.

Lower the plasma burner to the recommended

height.

Plasma burner component parts are

worn

Check and replace worn parts.

Workpiece no longer connected to

the grounding cable.

Check the connections.

Cutting speed too fast. Slow down the working speed

Burner sleeve is not straight

Metal is too thick. Several cycles necessary.

Plasma burner component parts are

worn

Check and replace worn parts.

Loading...

Loading...