18

3.6 Creating a material characteristic

The tension meter has been calibrated dynamic on material 1 according our SCHMIDT

procedure for a vertical material path and cannot be deleted or overwritten. The material

and diameter is given in chapter 2. Factory calibrations using customer supplied materi-

als follow the same procedure. In this case, however, the calibration on Schmidt material

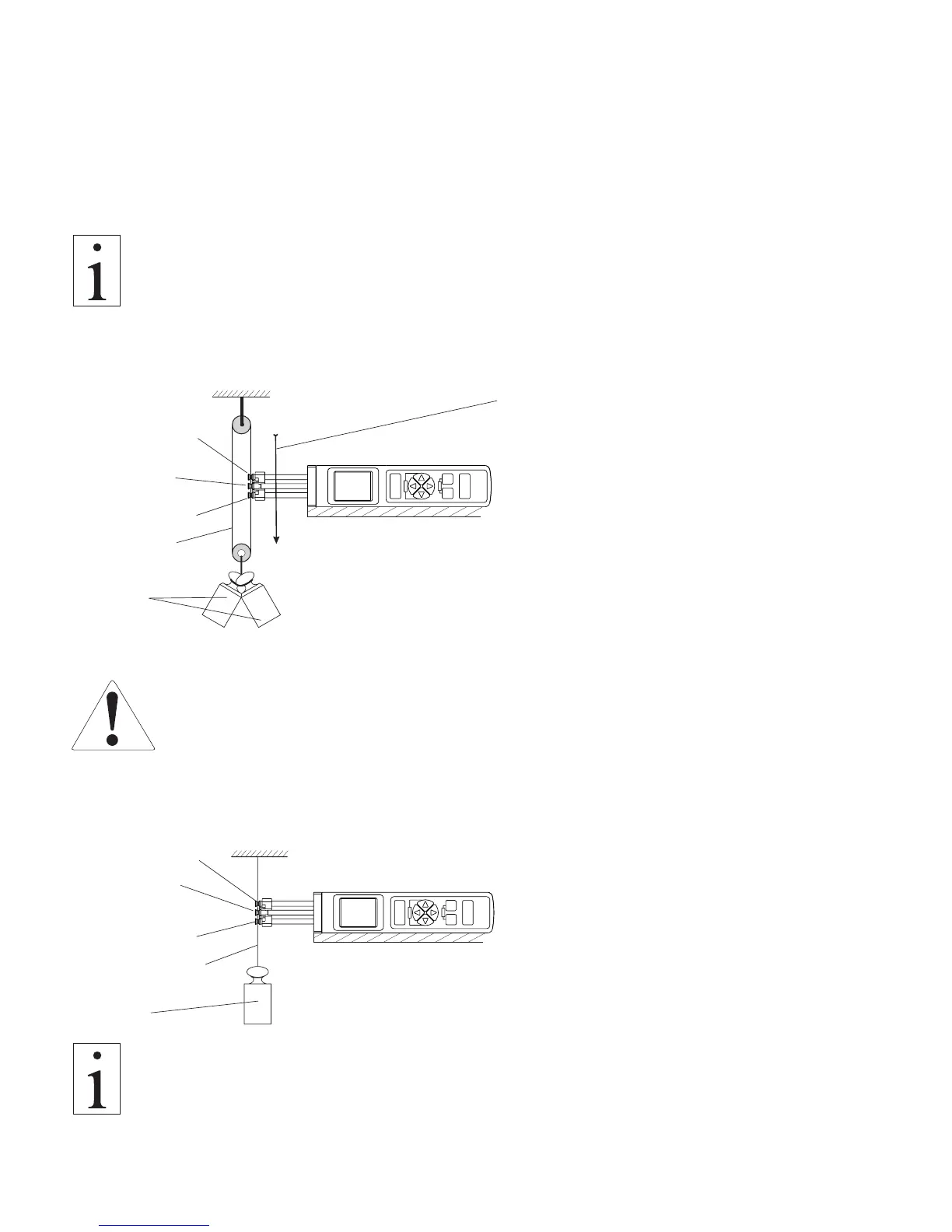

1 is omitted. Fig. 3.6.1a shows a measuring setup for the dynamic calibration, while fig.

3.6.1b shows a measuring setup for the static calibration.

The material characteristics has been preset in the factory and cannot be over-

written. For these material characteristics, you can only change the damping fac-

tor, the alarm function setting, and the limit values.

3.6.1 Setup for calibration

Hang twice the weight (pulley effect) which corresponds to the tension to be

measured from the measured material, vertically, as shown here. Please keep

in mind to include the weight of the lower deflection pulley when you calcula-

te the suspended weight.

Running direction of the material to be

measrued

Line speed Vmax. = ETX 100 m/min

Vmax. = ETPX 60 m/min

Hang twice the weight (pulley effect) which

corresponds to the tension to be measu-

red from the measured material, vertically,

as shown here. Please keep in mind to

include the weight of the lower deflection

pulley when you calculate the suspended

weight. Pay attention to the correct unit of

measure.

dynamic calibration

fig. 3.6.1a

Weight

Material to

be measured

Guide rollers

Guide rollers

Measuring

rollers

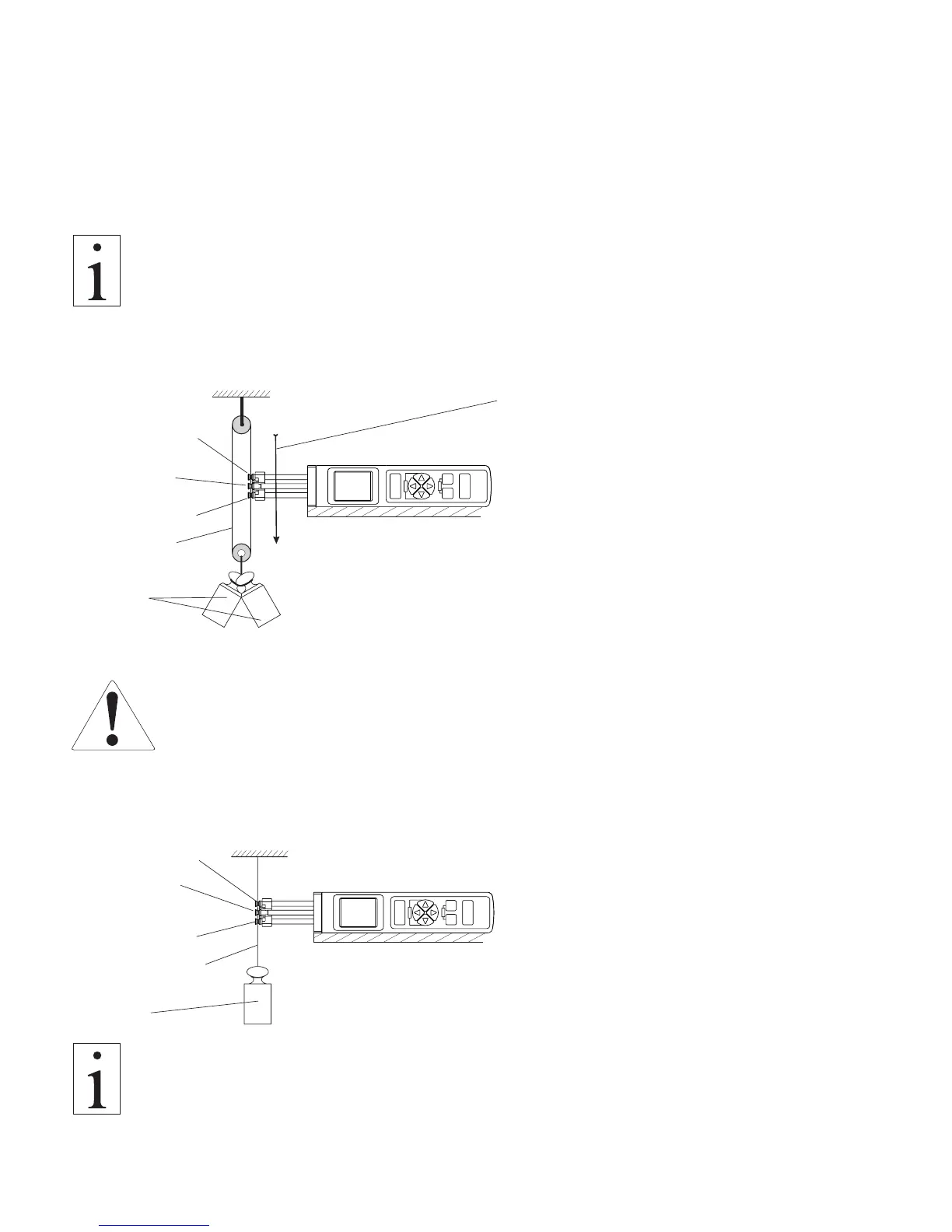

Hang a weight which corresponds to

the tension to be measured from the

measured material, vertically, as shown

here. Pay attention to the correct unit of

measure.

fig. 3.6.1b

Weight

Material to be

measured

Guide rollers

Guide rollers

Measuring

rollers

static calibration

The tension meter has been calibrated dynamically (fig. 3.6.1a) according to the

SCHMIDT factory procedure. Therefore, differences may occur between static and

dynamic readings.

Loading...

Loading...