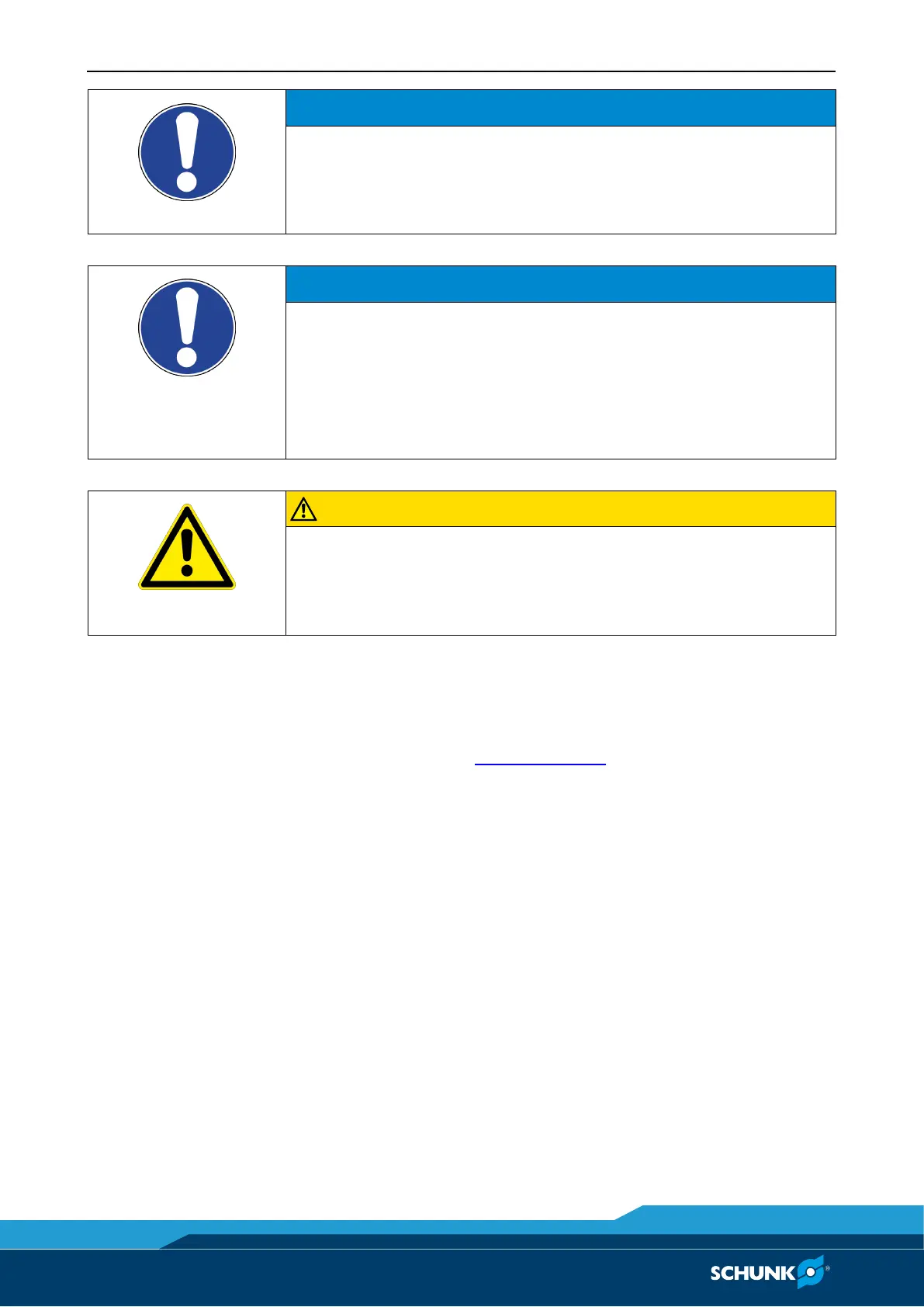

34 01.00|ROTA THWplus |en

The chuck piston (item 3) must not be moved so long as the jaw

change key (item 90) is located in one of the jaw-change bolts

(item 8) for the chuck.

Risk of damage to the chuck.

The mechanical system of the chuck is opened when the protec-

tion sleeve (item 4) is changed. No chips may penetrate into the

mechanical system of the chuck. If no protection sleeve is in-

stalled in the chuck, then the chuck must not be actuated and

the chuck piston (item 5) must not be moved!

Risk of damage to the chuck.

Risk of crushing due to mechanical system of the chuck being

open when the protection sleeve is being changed.

Do not reach into the open mechanical system of the chuck!

Base jaw position

A marking line between the jaw guides is milled on the face side of

the chuck (see drawing( 12, Page 41)

). This marking line is the

positioning aid for the base jaws or top jaws. The outermost base

jaw or monoblock position is reached when the front face of the

base jaw or the unsplit top jaw agrees with the marking line in the

jaw change position (chuck open).

It is vital that this jaw position is adhered to so that all teeth are

engaged for the force transmission from the wedge bars to the

base jaws or top jaws.

Change or supplement of jaws

Jaws for highest repeatability must be bored and ground in the

chuck under clamping pressure.

• When boring and grinding it is important that the boring ring or

the boring bolts are clamped by the top jaws – and not by the

base jaws. Keep base and top jaws screwed together for later

tasks.

Loading...

Loading...