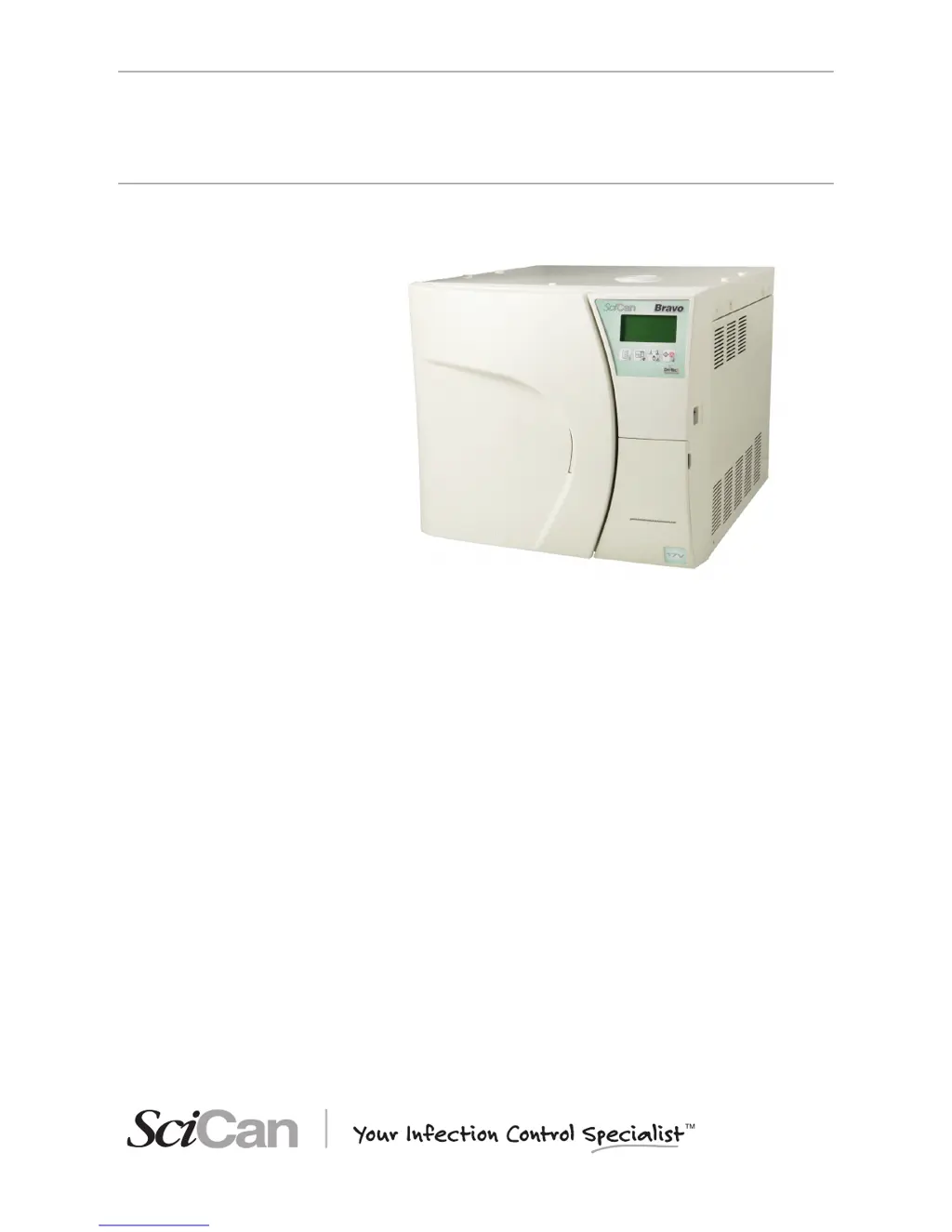

What to do if I can't open the door of my SciCan BRAVO 17V after the cycle?

- DDouglas CarlsonAug 19, 2025

If you can't open the door of your SciCan laboratory equipment after the cycle completes, it could be due to residual pressure in the sterilization chamber. Wait until the pressure returns to 0.00 bar before trying again. Also, check if the bacteriological filter is clogged and replace it if necessary.