15

5. In the reverse of step 1, slide the PatchStar assembly back onto the rotary base

and tighten the 2 dovetail locking screws on the Y axis (green).

3.2.2 Setting the rotational stops on the rotary base

The rotary base allows the PatchStar to be rotated between two magnetic stops 100° apart.

The magnetic stops provide enough force to hold the PatchStar in place for the application

but can be easily moved by hand between stops without having to undo any locking

mechanism or use any tools. The magnetic stops are moved together to set up the

positioning of the PatchStar.

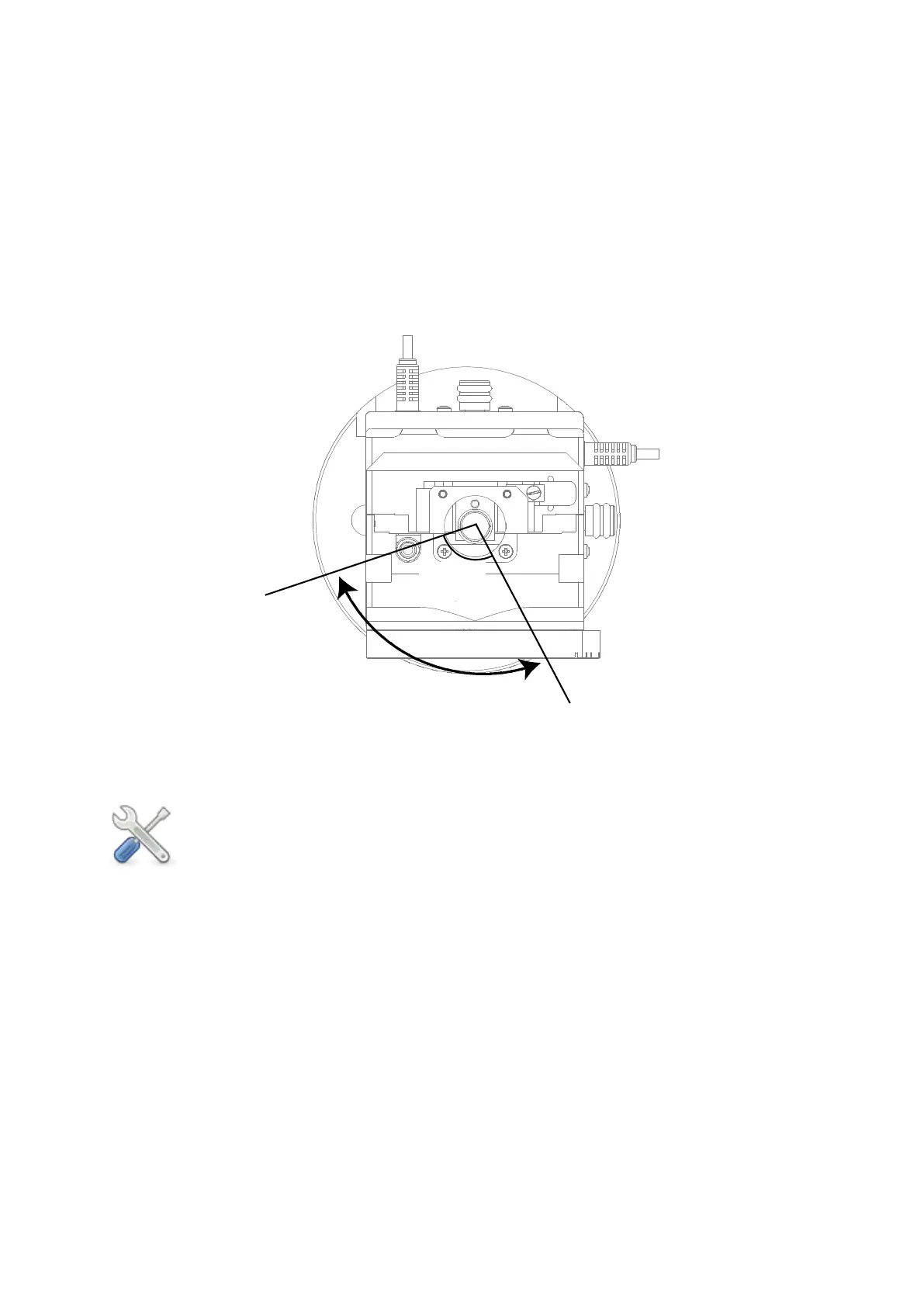

Figure Q: View from above, showing fixed degree of movement between the adjustable

magnetic stops

The following steps should be undertaken with the PatchStar fitted onto a rotary

base, which in turn has been fixed to the mounting surface. Please unplug all

cables from the breakout box before undertaking this process to prevent twisting

the cables – remember to power off the 1U rack controller before removing these

cables.

Right PatchStar

1. Ensure at least one of the grub screws in the rotary base is tight and then move the

PatchStar clockwise until it hits the stop.

2. Loosen the grub screw and move the base into the required position for the experiment.

3. Tighten the grub screw and check you can rotate the Patchstar anti-clockwise away from

the experiment to the other stop.

Left PatchStar

1. Ensure at least one of the grub screws in the rotary base is tight and then move the

PatchStar anti-clockwise until it hits the stop.

2. Loosen the grub screw and move the base into the required position for the experiment.

Fixed at

100°

Magnetic Stop at

Patching Position

Magnetic Stop at

Exchange Position

Loading...

Loading...