PRO-PAK

4

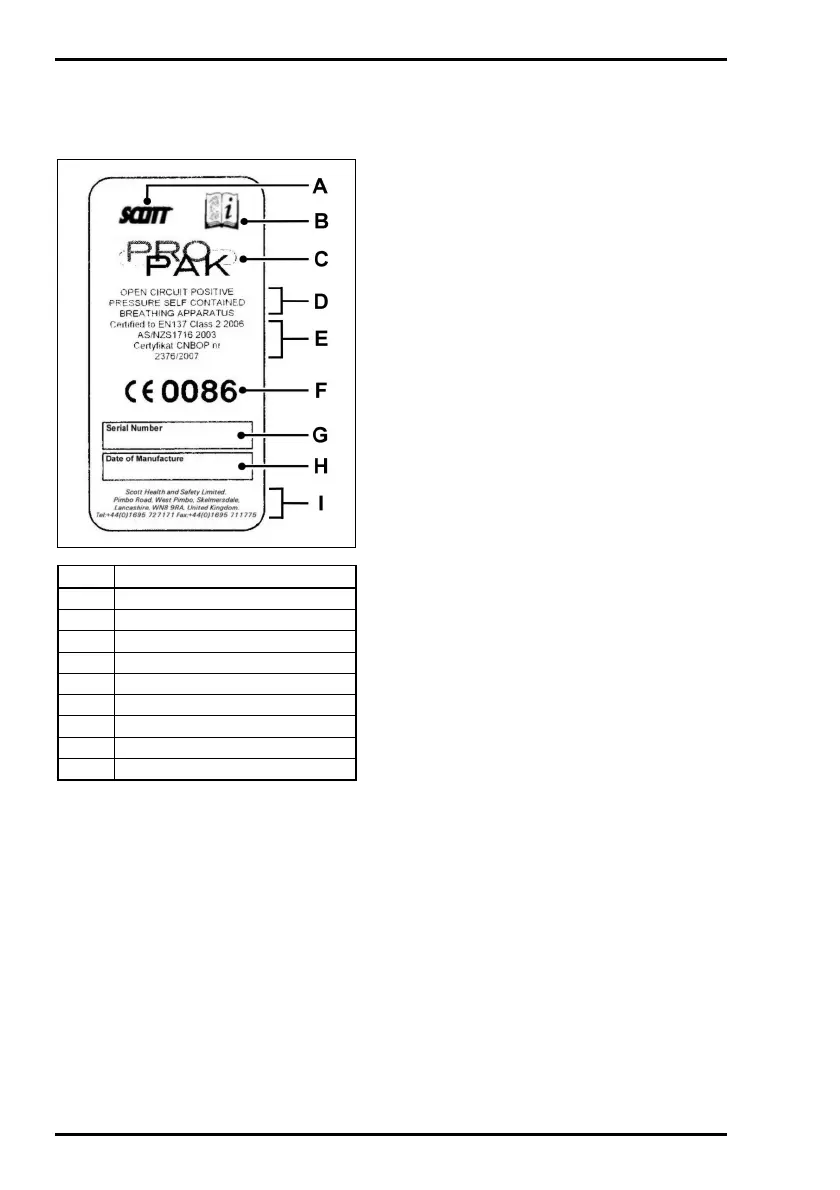

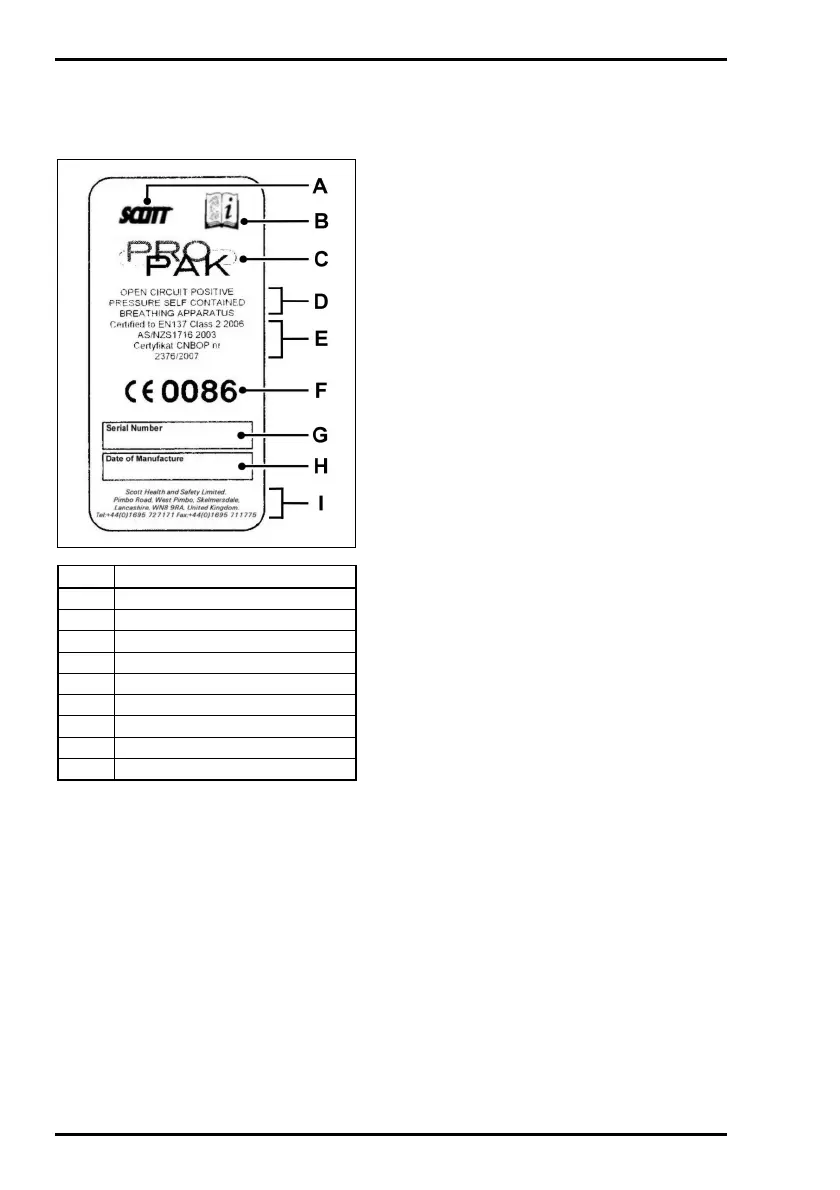

Pro-Pak is marked in accordance with

EN 137 : 2003 and AS/NZS1716 : 2003.

An explanation of those markings is given

below:

Key Meaning

A =

Product brand name

B =

Symbol - refer to User Instructions

C =

Product model/designation

D =

Apparatus description

E =

Standards to which apparatus is certified

F =

Number of Approval Body

G =

Serial number of apparatus

H =

Date of manufacture

I =

Contact details of manufacturer

2.2 HARNESS

The Pro-Pak harness is made from

flame-retardant Kevlar

TM

and Nomex

TM

.

The buckles are manufactured from

stainless steel, chromium-plated steel or

brass; and the press-studs from brass or

nickel-plated brass.

For wearer comfort, a lumbar pad or full

back pad is provided. Both are fabricated

from flame-retardant material and packed

with flame retardant, closed cell foam.

The lumbar pad is held in place by four

press-studs. The full-length pad is held by

press studs and the harness straps.

2.3 CYLINDER BAND

Pro-Pak can be configured for use with

one or two (Duo) 200, 207 or 300 bar,

steel or fully wrapped aluminium carbon

fibre composite cylinders (see Table 3).

Cylinders are secured to the lightweight

back-plate by a webbing cylinder band

and a cylinder valve retainer (CVR).

The webbing cylinder band is secured

around the cylinder(s) by a hinged, clamp

mechanism with a thumb-operated

release tag that prevents accidental

opening. The band can be adjusted to

accept the range of cylinders listed in

Table 3. The clamp mechanism facilitates

replacement of similar size cylinders

without cylinder band adjustment.

Pro-Pak Duo cylinder bands can easily

be altered by the wearer (no tools

required) to mount a single cylinder,

centrally on the back-plate.

2.4 THE PNEUMATIC

SYSTEM

The pneumatic system has two pressure

reduction stages: air from the cylinder is

reduced to a medium-pressure (MP) of

between 5.5 and 11 bar by the reducer.

The second pressure reduction is

performed in the facemask Demand

Valve (DV).

Air from the cylinder passes through a

sintered bronze particle filter in the

cylinder connector, which protects the

pneumatic system, then through a short

length of high-pressure (HP) braided

hose to the reducer inlet manifold.

Loading...

Loading...