Description of operation of the power sources and technical dates 11

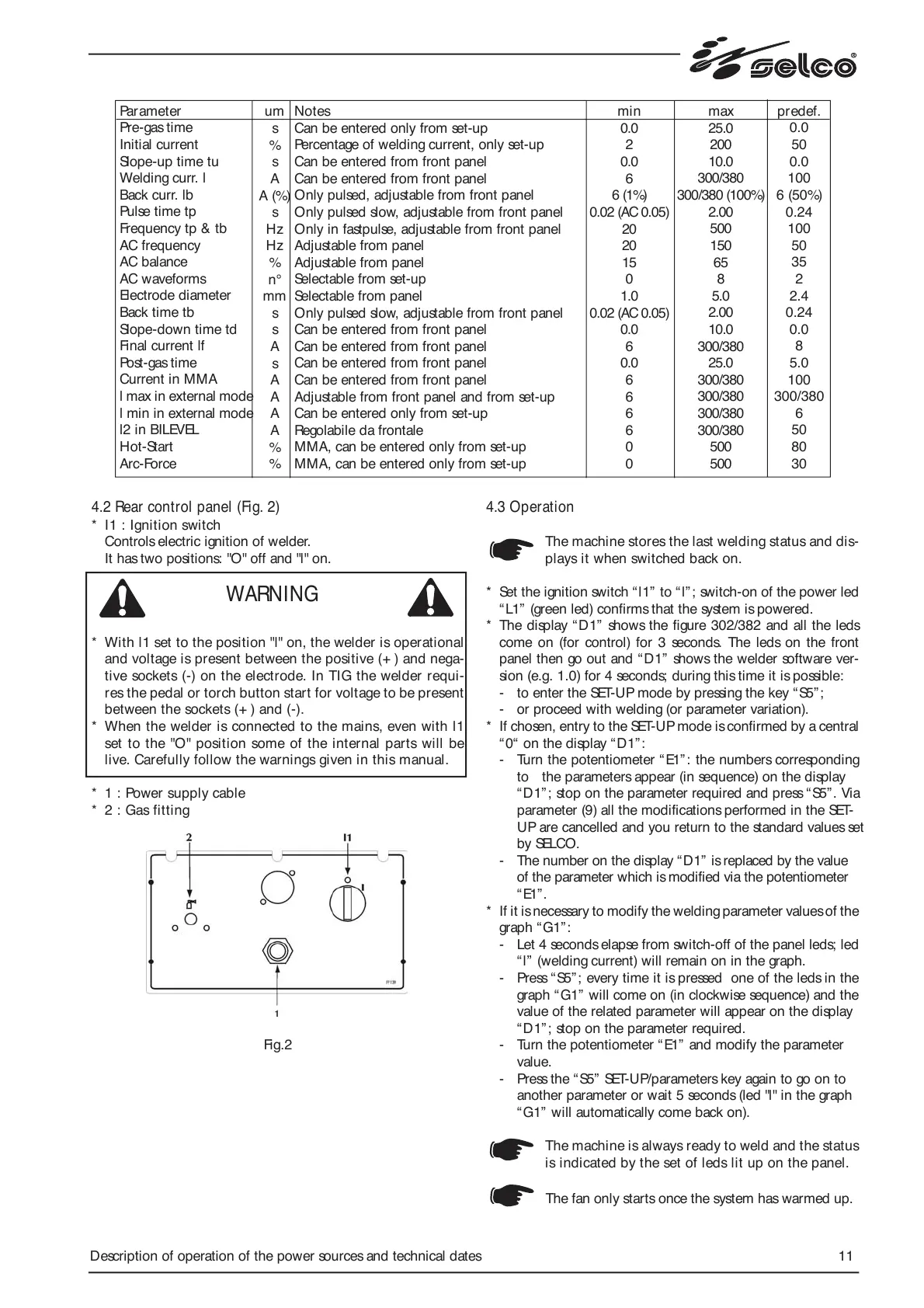

4.2 Rear control panel (Fig. 2)

* I1 : Ignition switch

Controls electric ignition of welder.

It has two positions: "O" off and "l" on.

* With l1 set to the position "l" on, the welder is operational

and voltage is present between the positive (+ ) and nega-

tive sockets (-) on the electrode. In TIG the welder requi-

res the pedal or torch button start for voltage to be present

between the sockets (+ ) and (-).

* When the welder is connected to the mains, even with l1

set to the "O" position some of the internal parts will be

live. Carefully follow the warnings given in this manual.

* 1 : Power supply cable

* 2 : Gas fitting

Fig.2

4.3 Operation

The machine stores the last welding status and dis-

plays it when switched back on.

* Set the ignition switch “l1” to “l”; switch-on of the power led

“L1” (green led) confirms that the system is powered.

* The display “D1” shows the figure 302/382 and all the leds

come on (for control) for 3 seconds. The leds on the front

panel then go out and “D1” shows the welder software ver-

sion (e.g. 1.0) for 4 seconds; during this time it is possible:

- to enter the SET-UP mode by pressing the key “S5”;

- or proceed with welding (or parameter variation).

* If chosen, entry to the SET-UP mode is confirmed by a central

“0“ on the display “ D1”:

- Turn the potentiometer “ E1”: the numbers corresponding

to the parameters appear (in sequence) on the display

“D1”; stop on the parameter required and press “S5”. Via

parameter (9) all the modifications performed in the SET-

UP are cancelled and you return to the standard values set

by SELCO.

- The number on the display “D1” is replaced by the value

of the parameter which is modified via the potentiometer

“E1”.

* If it is necessary to modify the welding parameter values of the

graph “ G1”:

- Let 4 seconds elapse from switch-off of the panel leds; led

“l” (welding current) will remain on in the graph.

- Press “S5”; every time it is pressed one of the leds in the

graph “ G1” will come on (in clockwise sequence) and the

value of the related parameter will appear on the display

“D1”; stop on the parameter required.

- Turn the potentiometer “E1” and modify the parameter

value.

- Press the “ S5” SET-UP/parameters key again to go on to

another parameter or wait 5 seconds (led "l" in the graph

“G1” will automatically come back on).

The machine is always ready to weld and the status

is indicated by the set of leds lit up on the panel.

The fan only starts once the system has warmed up.

WARNING

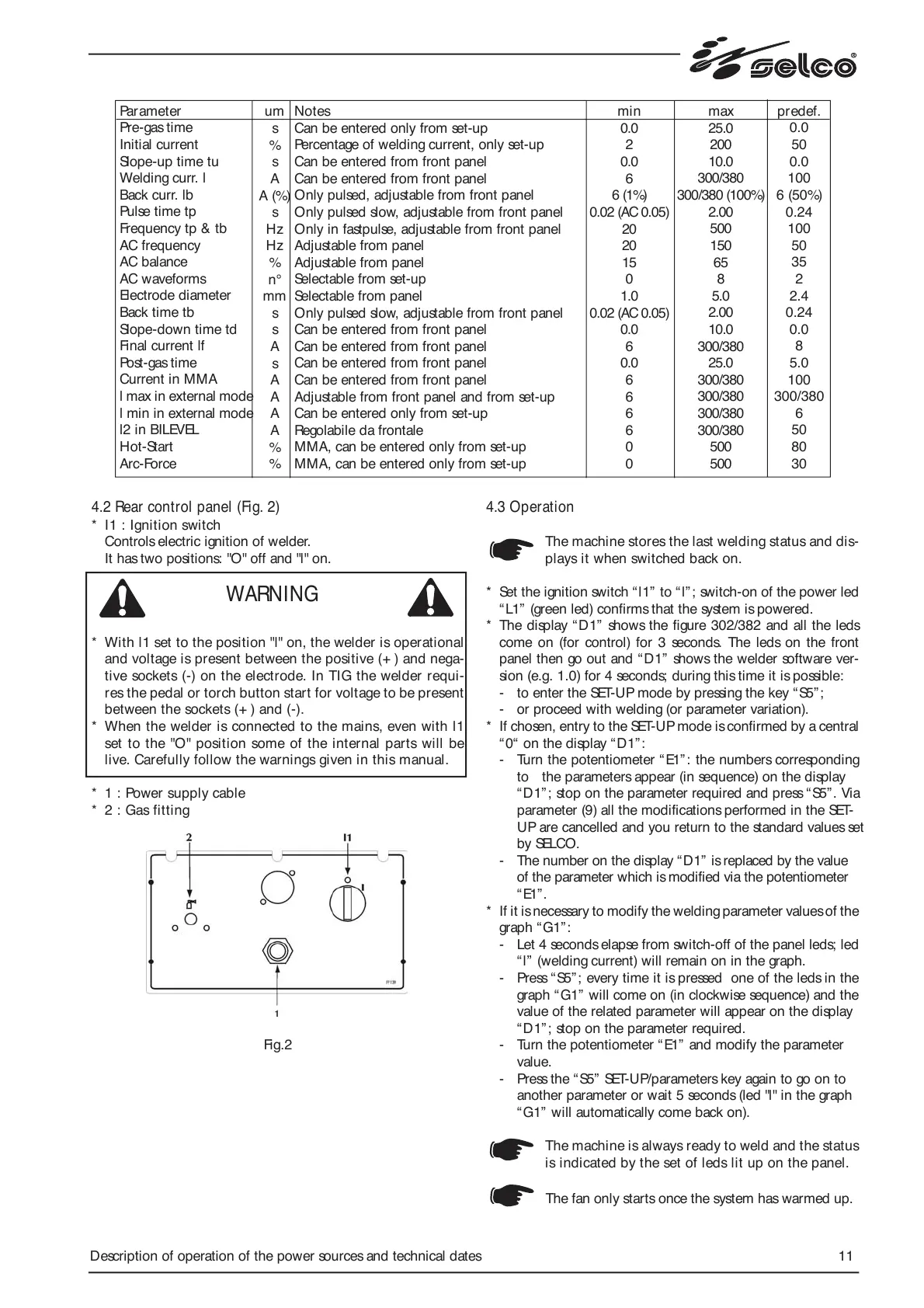

Parameter

Pre-gas time

Initial current

Slope-up time tu

Welding curr. l

Back curr. lb

Pulse time tp

Frequency tp & tb

AC frequency

AC balance

AC waveforms

Electrode diameter

Back time tb

Slope-down time td

Final current lf

Post-gas time

Current in MMA

l max in external mode

l min in external mode

l2 in BILEVEL

Hot-Start

Arc-Force

um

s

%

s

A

A (%)

s

Hz

Hz

%

n°

mm

s

s

A

s

A

A

A

A

%

%

min

0.0

2

0.0

6

6 (1%)

0.02 (AC 0.05)

20

20

15

0

1.0

0.02 (AC 0.05)

0.0

6

0.0

6

6

6

6

0

0

max

25.0

200

10.0

300/380

300/380 (100%)

2.00

500

150

65

8

5.0

2.00

10.0

300/380

25.0

300/380

300/380

300/380

300/380

500

500

predef.

0.0

50

0.0

100

6 (50%)

0.24

100

50

35

2

2.4

0.24

0.0

8

5.0

100

300/380

6

50

80

30

Notes

Can be entered only from set-up

Percentage of welding current, only set-up

Can be entered from front panel

Can be entered from front panel

Only pulsed, adjustable from front panel

Only pulsed slow, adjustable from front panel

Only in fastpulse, adjustable from front panel

Adjustable from panel

Adjustable from panel

Selectable from set-up

Selectable from panel

Only pulsed slow, adjustable from front panel

Can be entered from front panel

Can be entered from front panel

Can be entered from front panel

Can be entered from front panel

Adjustable from front panel and from set-up

Can be entered only from set-up

Regolabile da frontale

MMA, can be entered only from set-up

MMA, can be entered only from set-up

Loading...

Loading...