Description of operation of the power sources and technical dates 15

For TIG welding in the

torch is NOT liquid-

cooled, it is advisable to

close the cooling circuit

and make the connec-

tions illustrated in Fig.8:

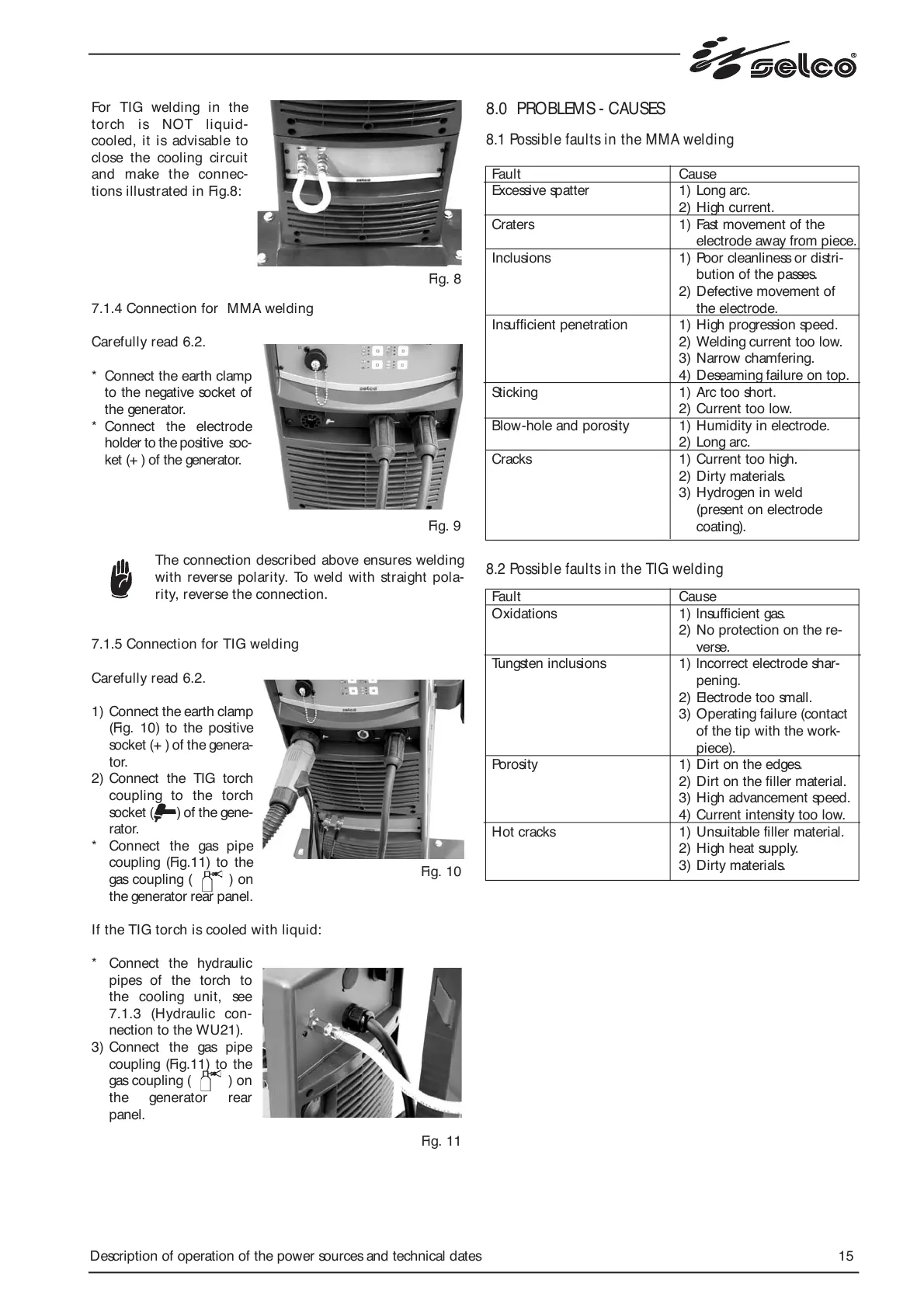

7.1.4 Connection for MMA welding

Carefully read 6.2.

* Connect the earth clamp

to the negative socket of

the generator.

* Connect the electrode

holder to the positive soc-

ket (+ ) of the generator.

The connection described above ensures welding

with reverse polarity. To weld with straight pola-

rity, reverse the connection.

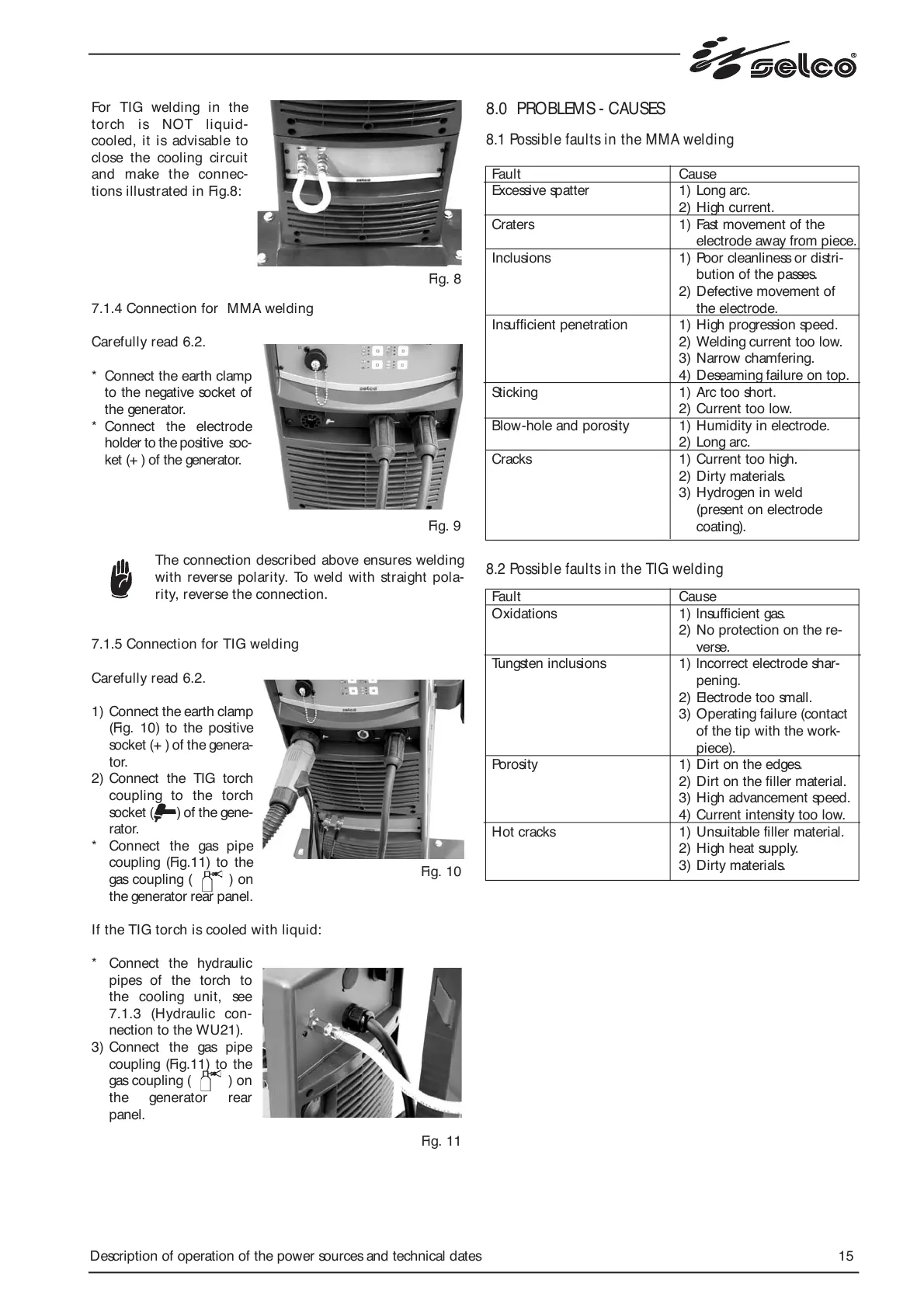

7.1.5 Connection for TIG welding

Carefully read 6.2.

1) Connect the earth clamp

(Fig. 10) to the positive

socket (+ ) of the genera-

tor.

2) Connect the TIG torch

coupling to the torch

socket ( ) of the gene-

rator.

* Connect the gas pipe

coupling (Fig.11) to the

gas coupling ( ) on

the generator rear panel.

If the TIG torch is cooled with liquid:

* Connect the hydraulic

pipes of the torch to

the cooling unit, see

7.1.3 (Hydraulic con-

nection to the WU21).

3) Connect the gas pipe

coupling (Fig.11) to the

gas coupling ( ) on

the generator rear

panel.

8.0 PROBLEMS - CAUSES

8.1 Possible faults in the MMA welding

8.2 Possible faults in the TIG welding

Fault

Oxidations

Tungsten inclusions

Porosity

Hot cracks

Cause

1) lnsufficient gas.

2) No protection on the re-

verse.

1) lncorrect electrode shar-

pening.

2) Electrode too small.

3) Operating failure (contact

of the tip with the work-

piece).

1) Dirt on the edges.

2) Dirt on the filler material.

3) High advancement speed.

4) Current intensity too low.

1) Unsuitable filler material.

2) High heat supply.

3) Dirty materials.

Fig. 8

Fault

Excessive spatter

Craters

Inclusions

Insufficient penetration

Sticking

Blow-hole and porosity

Cracks

Cause

1) Long arc.

2) High current.

1) Fast movement of the

electrode away from piece.

1) Poor cleanliness or distri-

bution of the passes.

2) Defective movement of

the electrode.

1) High progression speed.

2) Welding current too low.

3) Narrow chamfering.

4) Deseaming failure on top.

1) Arc too short.

2) Current too low.

1) Humidity in electrode.

2) Long arc.

1) Current too high.

2) Dirty materials.

3) Hydrogen in weld

(present on electrode

coating).

Fig. 9

Fig. 10

Fig. 11

Loading...

Loading...