8

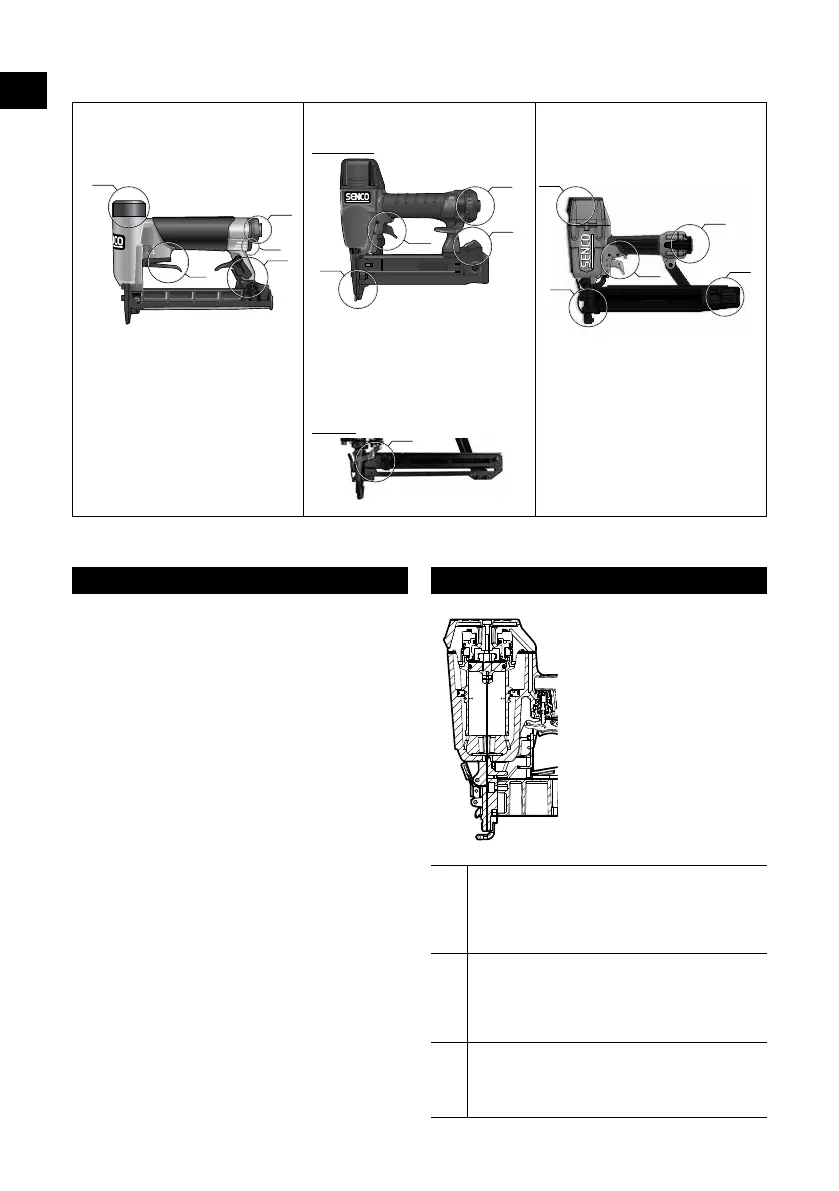

MAINTENANCE

1

SYMPTOM

Air leak near top of tool. / Sluggish operation

SOLUTION

Verify air supply / tighten screws or install Repair

Kit – See Parts Manual

2

SYMPTOM

Air leak near bottom of tool / Poor return.

SOLUTION

Clean tool / tighten screws or install Repair Kit

See Parts Manual

3

SYMPTOM

Other problems.

SOLUTION

Contact SENCO.

TROUBLE SHOOTING

TOOL ELEMENTS

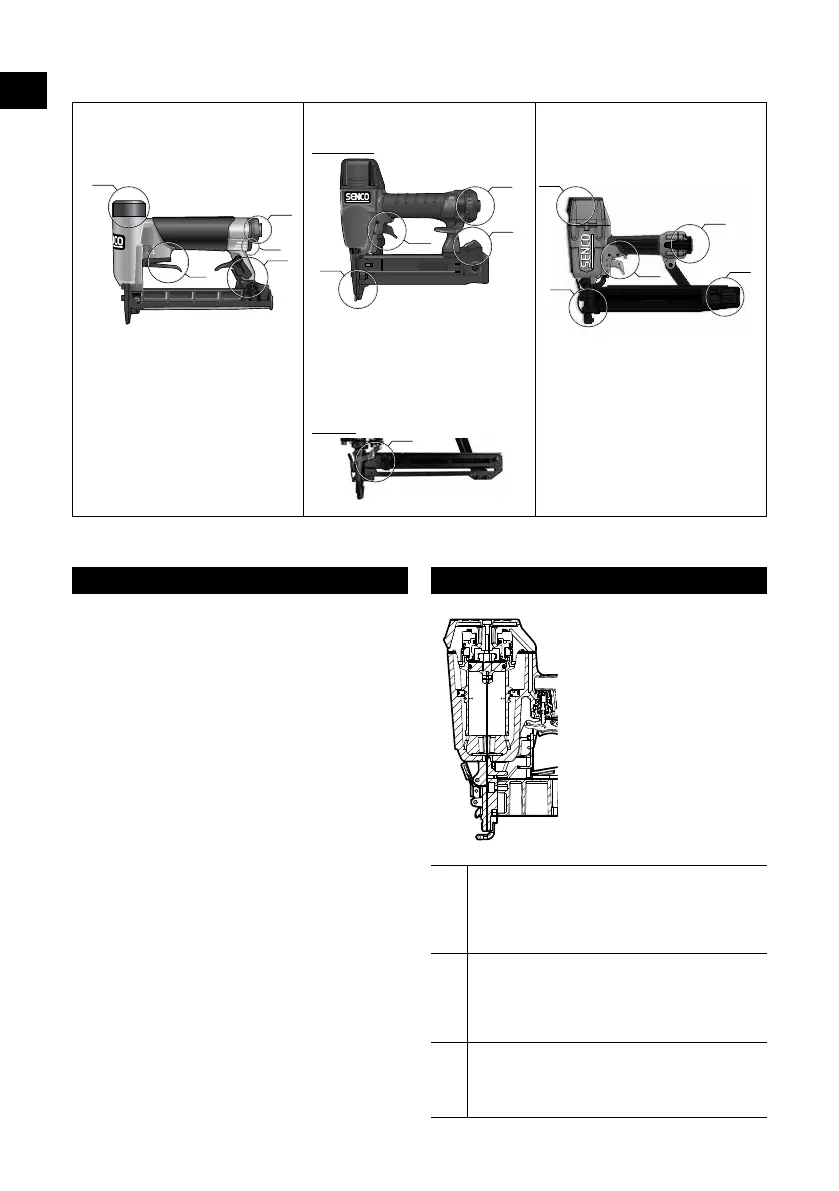

Fine Wire Stapler Medium Wire Stapler Heavy Wire Stapler

FW1 Magazine Release

FW2 Cap

FW3 Trigger

FW4 Inlet

FW5 Exhaust

HW1 Workpiece Contact

HW2 Exhaust

HW3 Trigger

HW4 Feeder Shoe

HW5 Inlet

HW5

HW2

HW1

HW4

HW3

FW2

FW3

FW1

FW4

FW5

MW1 Workpiece Contact

MW2 Trigger

MW3 Exhaust

MW4 Inlet

MW5 Magazine Release

MW1

MW2

MW5

MW3

MW4

Bottom Load

Top Load

MW6 Feeder Shoe

MW6

EN

Warning

y

Repairs other than those described here should be

performed only by trained, qualified personnel. Contact

SENCO for information at:

+31 320 295 575.

y

Read section titled “Safety Warnings” before maintaining

tool.

y

Only use spare parts specified by manufacturer or autho-

rized representative.

_______________________________________________

y

All screws should be kept tight. Loose screws result in

unsafe operation and parts breakage.

y

Check monthly

_______________________________________________

y

With tool disconnected, make daily inspection to assure

free movement of workpiece contact and trigger. Do not

use tool if workpiece contact or trigger sticks or binds.

_______________________________________________

y

Squirt Senco pneumatic oil (5 to 10 drops) into the air

inlet twice daily (depending on frequency of tool use).

Other oils may damage O-rings and other tool parts.

y

Some Senco tools are Oil Free and DO NOT require oil,

Check label.

_______________________________________________

y

Wipe tool clean daily and inspect for wear. Use non-

flammable cleaning solutions only if necessary.

y

Do Not Soak.

y

Caution: Such solutions may damage O–rings and other

tool parts.

y

Dispose of cleaning materials properly.

Should Staple Jam Occur:

Disconnect Air Supply

Remove Fasteners

Clear the Jam

Follow loading Procedure

Loading...

Loading...