METIS M308 / M309 / M313 / M316 / M318 / M323 / H309 / H316 / H318 (12-pin)

Configuring the Pyrometer

27

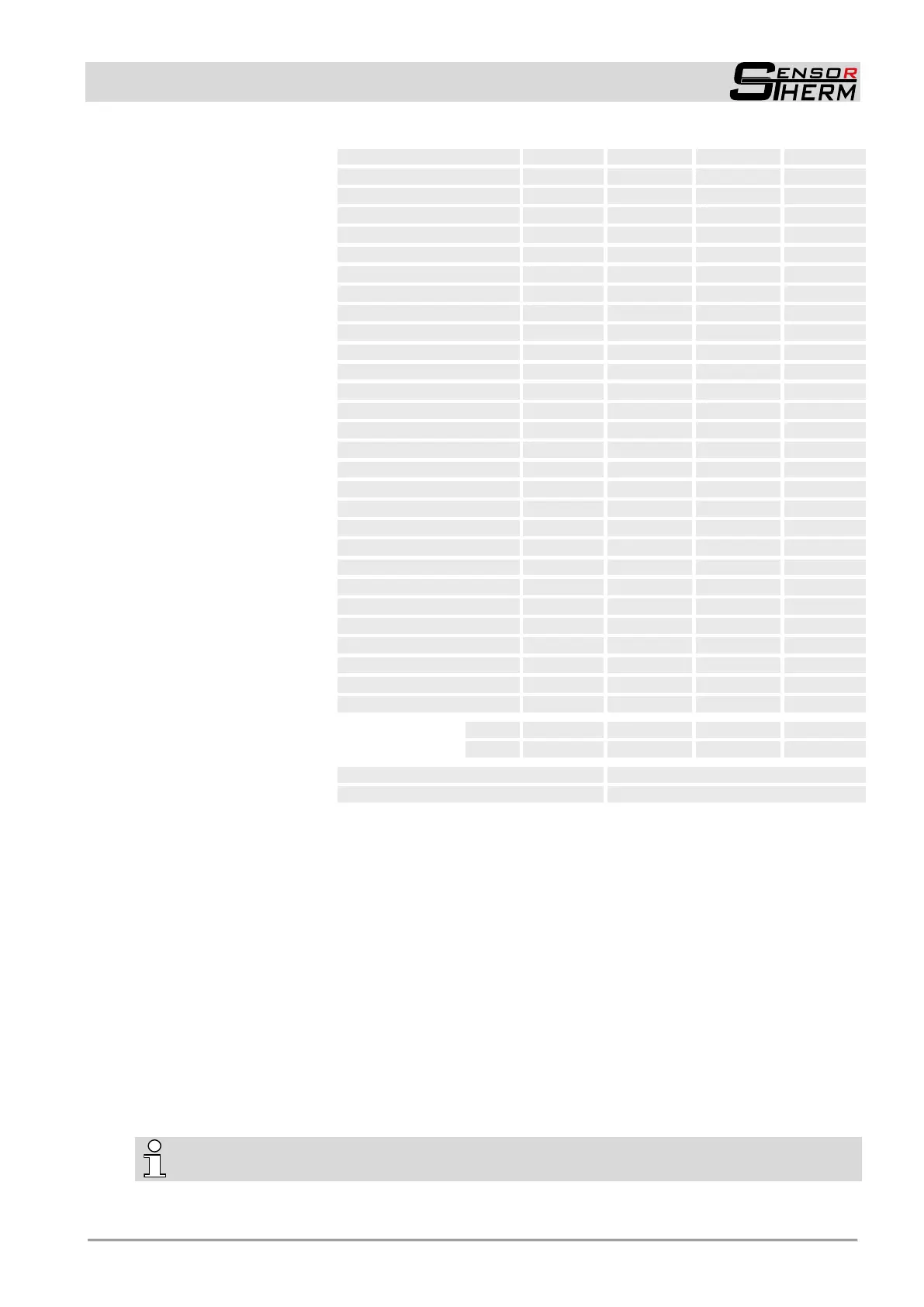

texture alloy components

play an important role for

the emissivity.

Is a range given, this is

related to differences in

the nature of the sur-

face from smooth to

rough, rough surfaces

have higher emissivities

(for determining the cor-

rect emissivity also a

comparison measure-

ment can be performed

with a thermocouple).

The emissivities with

"shiny" refer to applica-

tions that are performed

under an inert gas or in

a vacuum.

“n.s.“ means that no

values exist for this

wavelength range (not

specified), e.g. because

a reasonable meas-

urement in this wave-

length or temperature

range is not possible.

Measurement deviations at a 10% false set

emissivity at a temperature of 700°C:

Materials has a maximum emissivity of 1 (100%). However, a setting of up to 1.2 can be used to com-

pensate for temperature corrections due to higher background reflection.

To determine the correct emissivity, also a comparative measurement with a thermocouple can be per-

formed.

6.3.4 Transmittance

Is a viewing window located between measuring object and pyrometer, the transmittance of the window

must be considered during the measurement. Enter the transmittance of the window in order to obtain a

correct measurement result.

6.3.5 Spot Size Fill Factor

Measurements of objects that are smaller than the pyrometer’s spot size can be performed when meas-

uring hot objects in front of a cold background. In this case the fill factor specifies how much percent the

measuring field is filled (see also 5.4 Alignment to the measuring object).

INFO: Emissivity, transmittance and spot size fill factor are directly related to each other, the re-

sult of the multiplication of the 3 parameters has to be minimum 5%.

Loading...

Loading...