METIS M308 / M309 / M313 / M316 / M318 / M323 / H309 / H316 / H318 (12-pin)

SensorTools Software

44

7.2.4 PID Controller Equipment

M3 and H3 pyrometers can optionally be equipped with an integrated PID controller. At this, the tem-

perature signal is converted into a control signal via a PID controller software. A setpoint value and the

necessary PID parameters are set to trigger a corresponding control value output. At the analog output

2, the control signal is provided, via display and analog output 1 the current temperature reading is

available (factory setting, assignment can be changed in the pyrometer port settings, see 6.3 Parame-

ters / Settings and 7.2.3 Device Settings and Configuration).

An integrated PID controller is automatically detected by the software and activates

the button for the controller configuration.

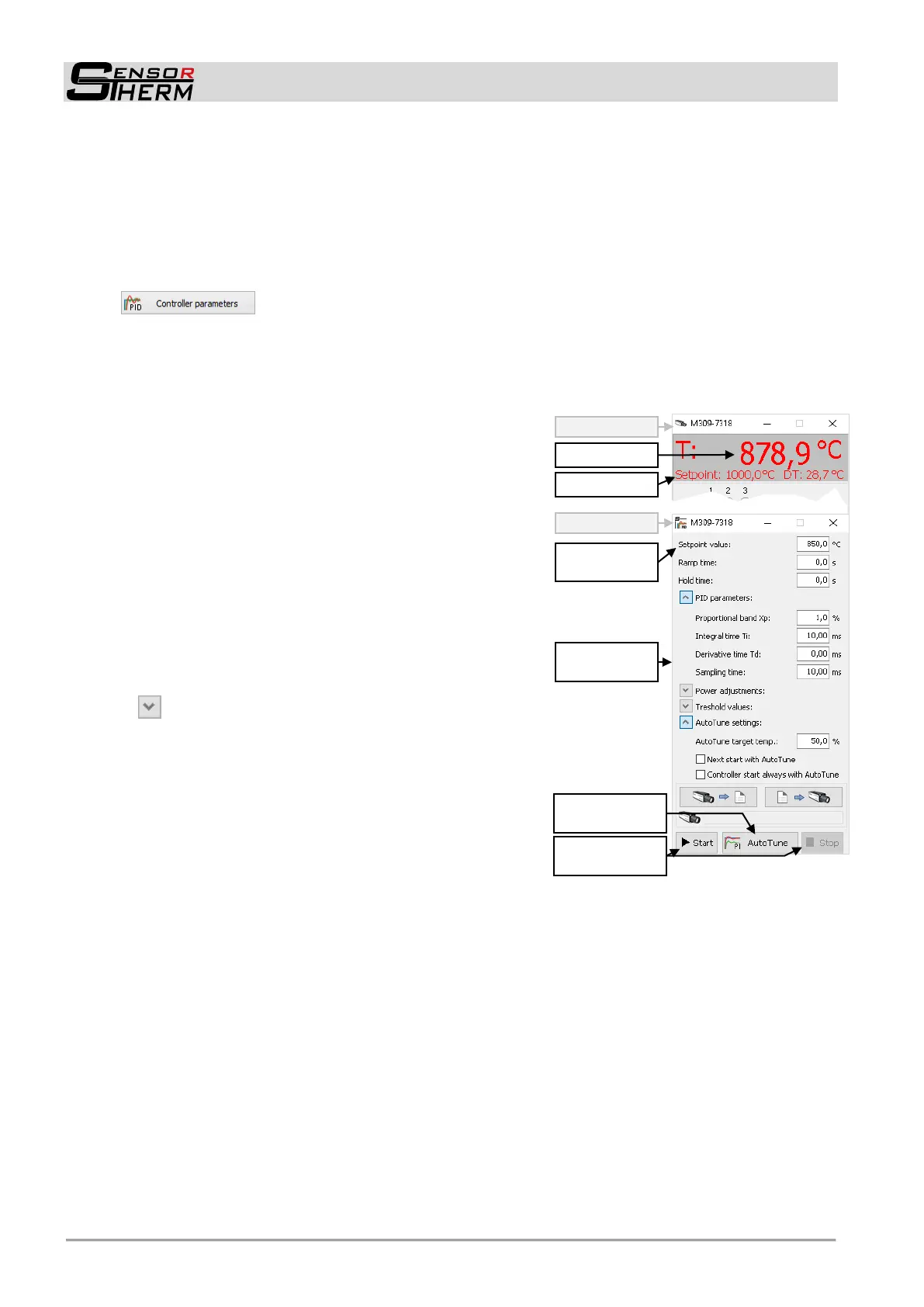

A setpoint and the necessary PID control parameters are entered directly in the software and trans-

ferred to the pyrometer by pressing the ENTER or tabulator key, control parameters also can be

changed during running control mode. Invalid value entries are automatically corrected to the next pos-

sible.

Control Parameters:

Always visible parameters:

- Setpoint value: Setpoint specification.

- Ramp time (in 100 ms): The setpoint temperature will

be approached by increasing the temperature with a

uniform gradient of the temperature within the entered

time (the setpoint temperature in the grey field above

can show updated ramp temperatures if the buffer

mode settings in the data collection settings (see

7.2.3.4) are set to “with state information”).

- Hold time: when reaching the desired value, the set-

point value in can be maintained at the current value.

The control process stops automatically after the hold

time is elapsed.

Click the expand icon to open the control parameters

sorted into groups.

PID parameters:

- Proportional band Xp: The proportional band repre-

sents the reciprocal of the gain of the controller (Enter-

ing 0.1-1000%, 0.1 = highest gain, 1000 = lowest gain).

- Integral time Ti: The integral time constant represents

a kind of smoothing or delay

(Note: Ti is a multiple of the sampling time. Therefore,

changes in the sample have an impact on this value).

- Derivative time Td: The derivative time constant slowdowns the rapid rise to prevent overshooting

(if, for example, the actual value has almost reached the target value but still strong increases, Td

slows a further increasing to prevent an overshoot).

(Note: Td is a multiple of the sampling time. Therefore, changes in the sample have an impact on

this value).

- Sampling time: Select how quick temperature values will be read out of the sensor. Select the pa-

rameter depending on the inertia of the heating process (Note: Ti and Td are a multiple of the

sampling time. Therefore, changes in the sampling effect changes in Ti and Td).

Power adaptation:

- P-min: The minimum control output power defines the power set to the control output at least.

- P-max: The maximum control output limits the power to the entered value.

- P-zsc: Limits the control output power as long as the beginning of the sensor’s or pyrometer’s

temperature range is reached. This is useful to avoid a too fast start of a heating process because

the object temperature is out of the pyrometer’s temperature range.

- P dynamic: Limits the power, the control output can control suddenly (standard 100%).

Start / Stop con-

trol process

Automatically find

control values

Loading...

Loading...