48

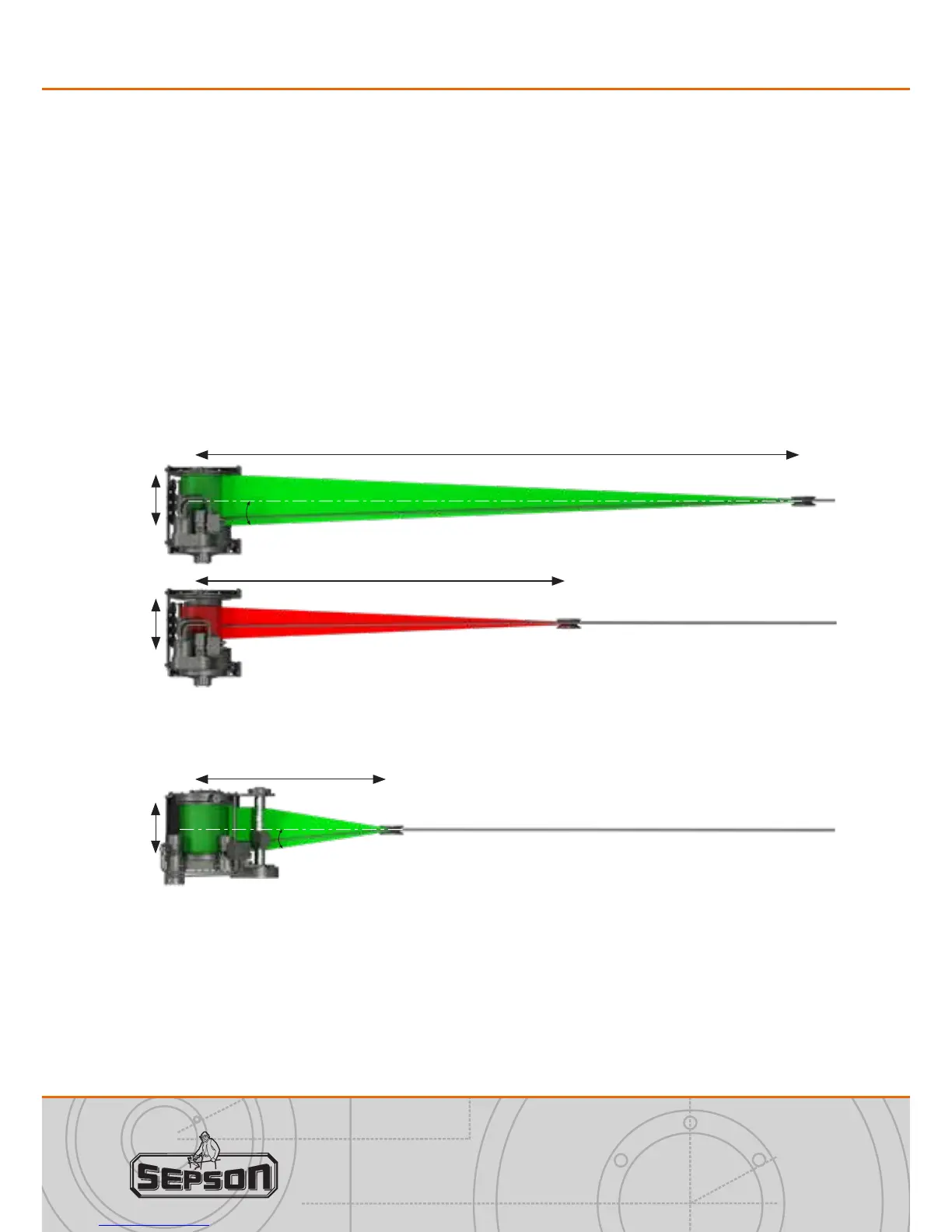

It is very essential that the rope is spooled on with as small angle as possible to a

line perpendicular from the centre of the rope drum. The eet angle (a) in the sketch

below should not be much greater than 2° to obtain a perfect spooling. If this angle

is bigger than 3.5° good spooling cannot be obtained. The rope will not spool

properly and will only spool onto one side of the drum.

The distance (D) from the centre of the rope drum to the rst rope sheave or roller

fairlead must be 10 times the drum width (W) and absolutely not less than 8 times

the drum width (W). If the distance is less than 8 times, it will be impossible to get

a good rope spooling. If the distance is less than 8 times the drum width (W), rope

spooling problems may occur.

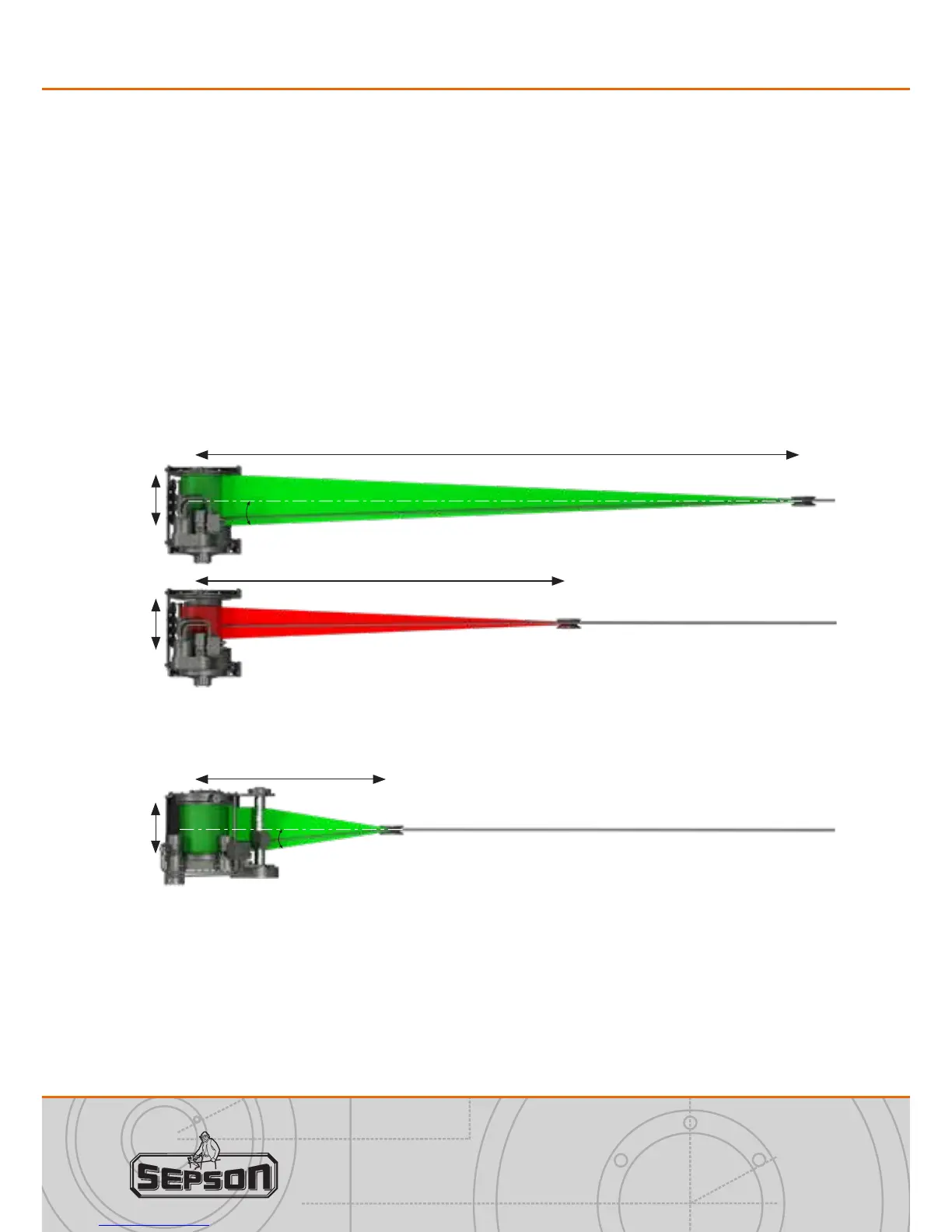

4.3 How to improve rope spooling

When installing a drum winch, mount the winch as far as possible from the rst rope

sheave or roller fairlead. Choose a winch with a drum width that allows you to have

the smallest possible eet angle. Observe that a narrow drum needs more rope

layers for the same length of rope than a wider drum and that the pulling force is re-

duced with the number of rope layers unless a constant pulling force device is used.

It will always compromise between eet angle and the least number of rope layers.

For winches with an automatic rope spooling device the eet angle (a) can be as

much as 15° corresponding to a relation between D/W of 2.

D

a

W

D = <10 x W

W

D

W

a

Winch basics

Loading...

Loading...