Service Manual

Integra E-Z Oxygen Concentrators

Chart SeQual Technologies Inc. Page 12 of 34 P/N 2917

3.2. Scheduled Preventive Maintenance (Use PN 4542-SEQ “Annual PM Kit”-

once every 12 Months(Annually) or as needed)

3.2.1. Replace the 9V Battery once every 12 Months(Annually) or when Battery Level is at 2

Bars:

Replace the 9V battery(8098-SEQ) annually or when the Battery Indicator

Level is at 2 Bars. To check this, enter Service Mode as described in Section

2.6.

3.2.2. Replace the Compressor Inlet Filter once every 12 months(Annually) or as needed:

Replace the compressor intake filter annually or as needed

depending upon the environment in which the concentrator is

operating. The compressor intake filter can become clogged

depending upon the amount of contaminants in the air (smoke,

dust, dirt, pollen, etc.) and may need to be changed more

frequently. Refer to the Troubleshooting Guide for signs of a

clogged filter and refer to the Replacement Parts section for the

correct compressor intake filter.

CAUTION:

Operation of the oxygen concentrator with a clogged compressor

intake filter will reduce the performance of the unit and can lead to

system damage and premature failure.

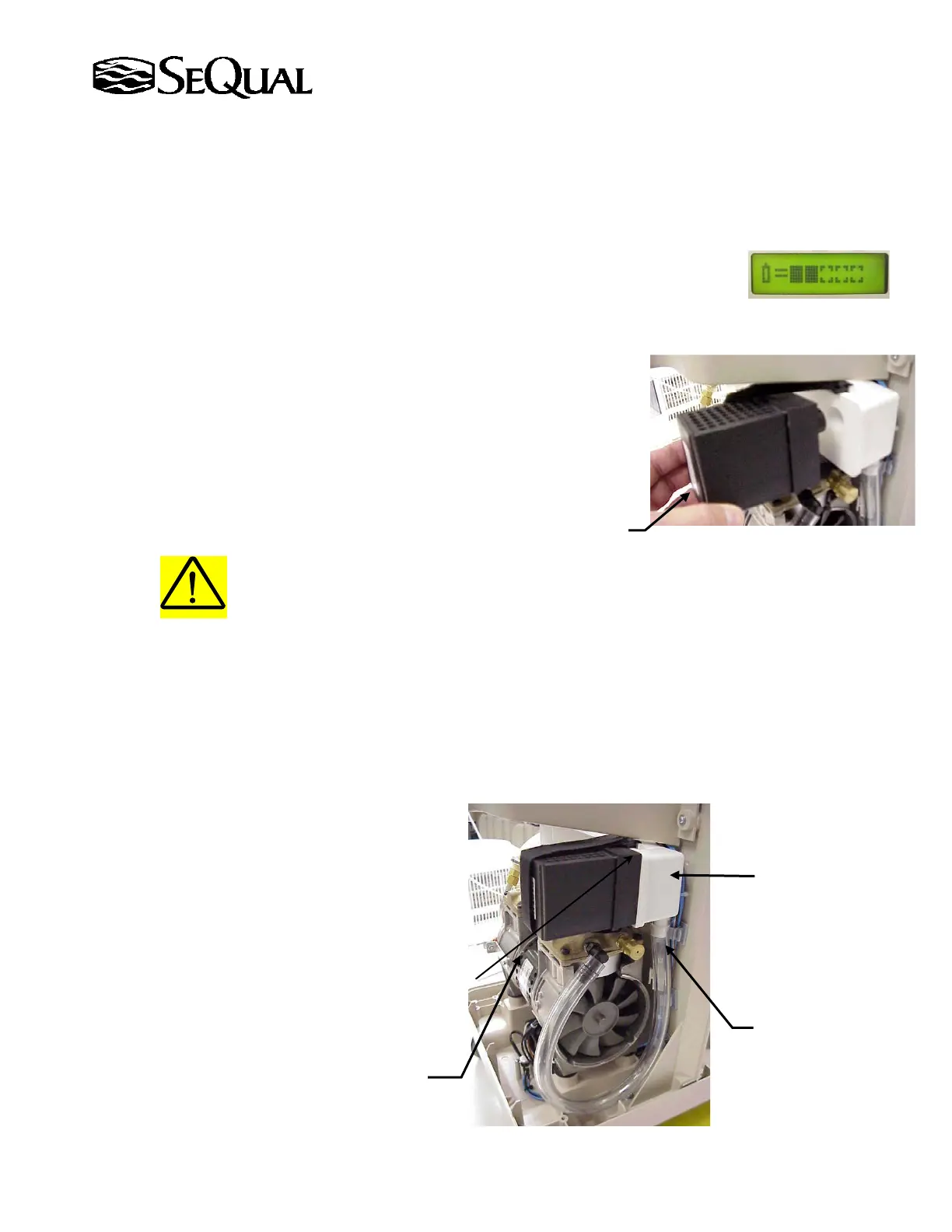

3.2.2.1.Open the hook and loop straps holding the Filter on the Filter/Muffler assembly. Hold the unit

and twist and pull the filter to remove it from the muffler. Insert outlet tube on Filter (2607-

SEQ) into the hole on the Muffler. Rotate the filter so that the two parts are lined up across the

top length and side. Firmly push the Filter into the Muffler until the two parts touch, and re-

secure the velcro loop strap.

3.2.2.2. In addition ensure the free end of the PVC Tubing is on the compressor Air Inlet Fitting barb.

NOTE:

The most common cause of

low concentration and eventual

system failure is a dirty or

clogged compressor inlet filter.

The environmental conditions

in which the unit is operated

determine the effective filter

life.

Attached to

filter to muffler

attached to

Muffler

FILTER

Loading...

Loading...