62

Manual – MOVI-PLC® advanced DHR41B for EtherNet/IP, Modbus/TCP and PROFINET IO

7

Examples for data exchange via Modbus/TCP

Configuration and Startup (Modbus/TCP)

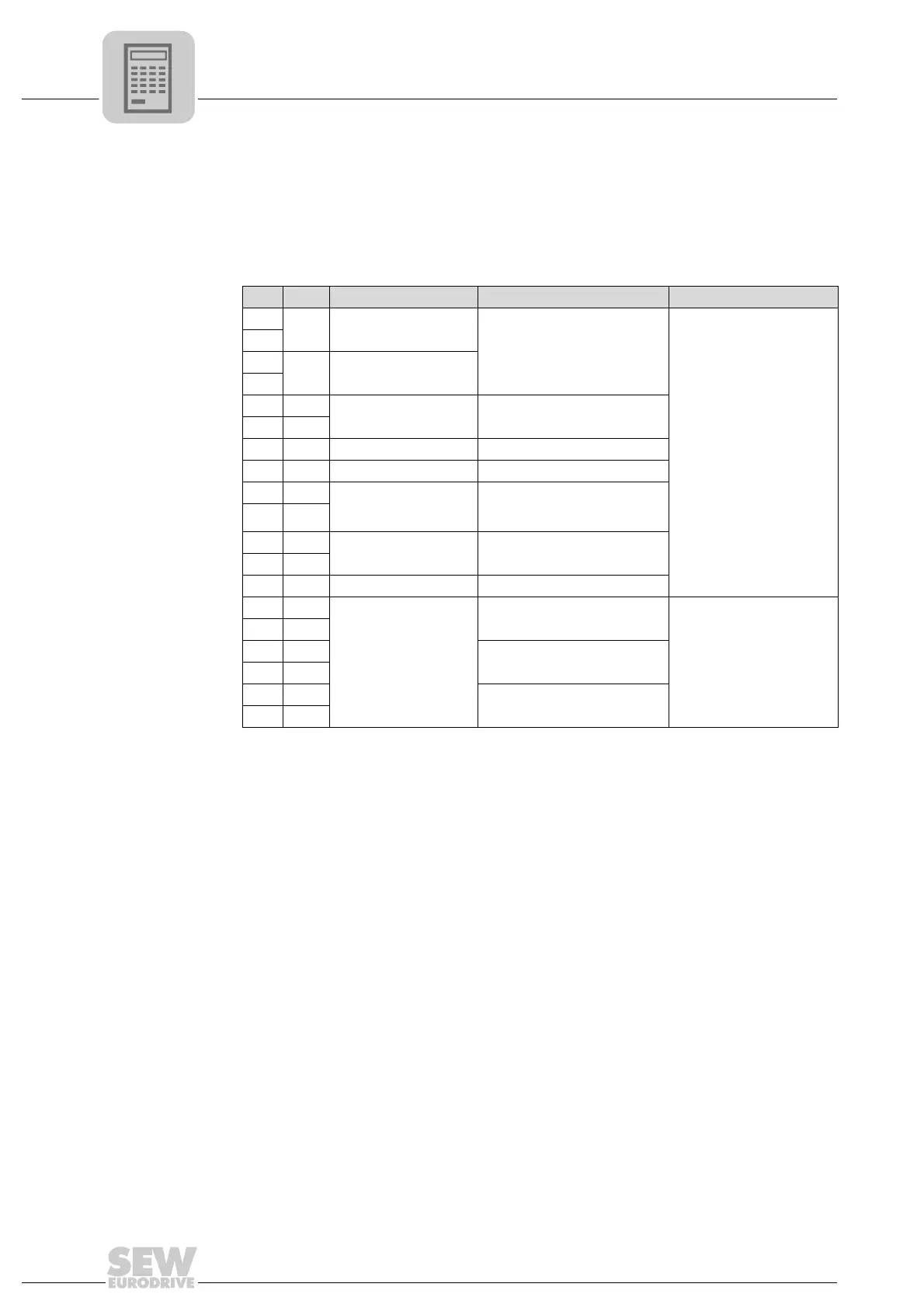

7.5.1 Writing and reading process data

The process data exchange can be performed either via FC3 (read) and FC16 (write),

or FC23 (read and write):

For writing 3 process data words (setpoints) to a Modbus/TCP slave via FC16, the

TCP/IP telegram to port 502 is structured as illustrated above.

Only bytes 0-11 are returned in the response telegram of port 502 of the Modbus/TCP

slave, where all values remain unchanged with the exception of byte 5. Byte 5 (low byte

length field) is corrected to value 6.

Byte Value Meaning Interpretation Help

0

0x00 Transaction identifier

For a detailed description,

refer to Modbus/TCP specifi-

cation and section 'Modbus

protocol (Modbus/TCP)'

1

2

0x00 Protocol identifier

3

40x00

Length field

Number of bytes after byte 5:

3 (no. of PD) × 2 + 7 = 13

50x0d

6 0xFF Unit identifier Must be 0 or 255

7 ox10 Function code Service = FC16 (write register)

80x00

Write reference number

Offset from where on the PD is

located:

Must always be 4

90x04

10 0x00

Write word count

Number of PDW (here 3):

Must for PD 1 64

11 0x03

12 0x06 Write byte count Number of PDW × 2 = 6

13 0x00

Data

Process output data word 1

Data mapping and definition,

see IEC program

14 0x11

15 0x22

Process output data word 2

16 0x33

17 0x44

Process output data word 3

18 0x55

Loading...

Loading...