33

27DV-S100

27DV-CS10

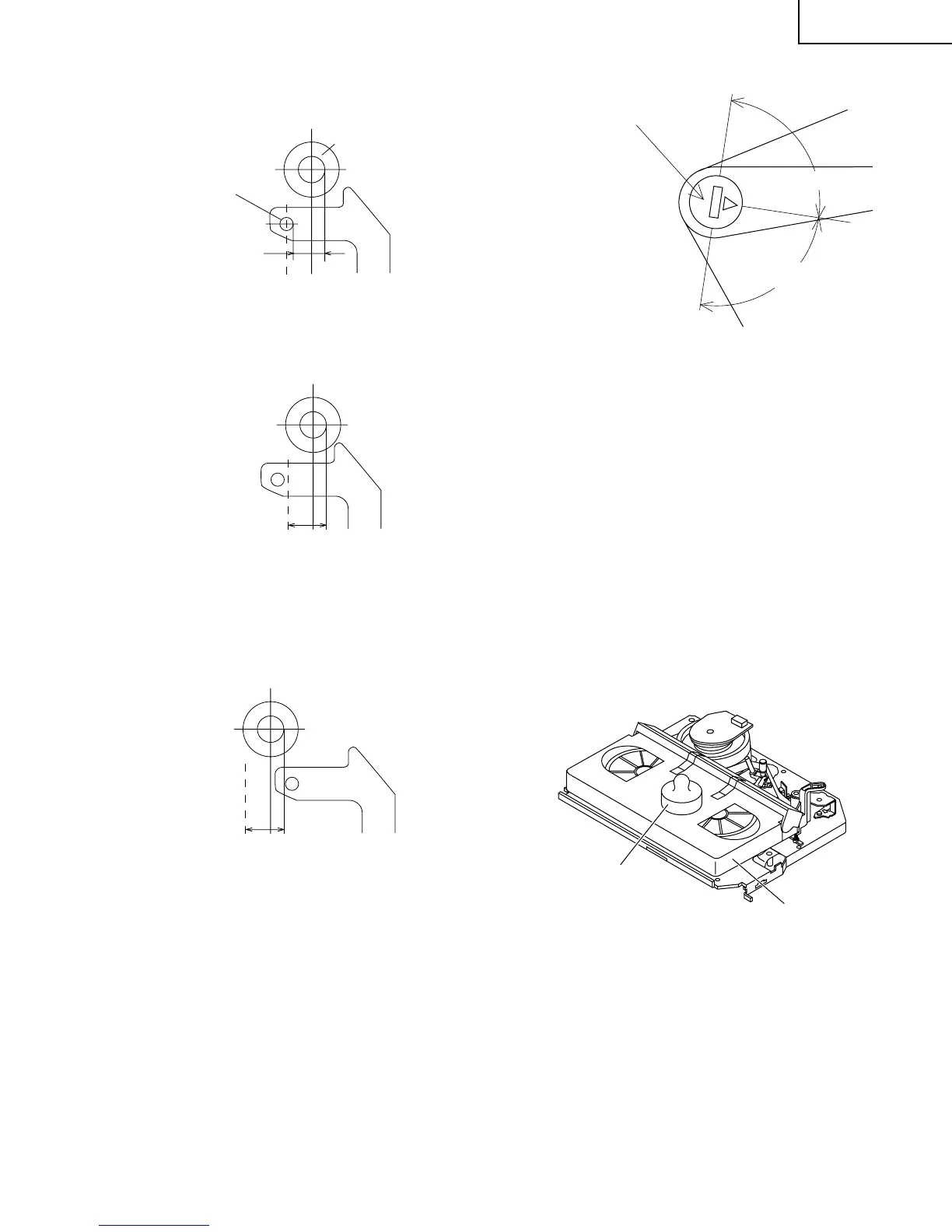

Figure 1-15.

2. Visually check to see if the right edge of the tension

pole is within the 2.3 ± 0.25 from the right edge of the

Sup guide shaft.

2.3 ± 0.25

Sup guide shaft

Tension pole

Make the adjustment with the beginning of a T-120 tape.

At left side from the center line

2.3 ± 0.25

Figure 1-16.

Insert the slotted screwdriver in the tension pole adjuster,

and rotate counterclockwise.

At right side from the center line

2.3 ± 0.25

Figure 1-17.

Insert the slotted screwdriver in the tension pole adjuster,

and rotate clockwise.

• Problems caused by maladjustments

1. Images onscreen may get distorted.

Tension pole adjuster adjusting range

90°

90°

Tension pole adjuster

Figure 1-18.

Adjust so that the delta mark of tension pole adjuster is

within 90° range (left, right).

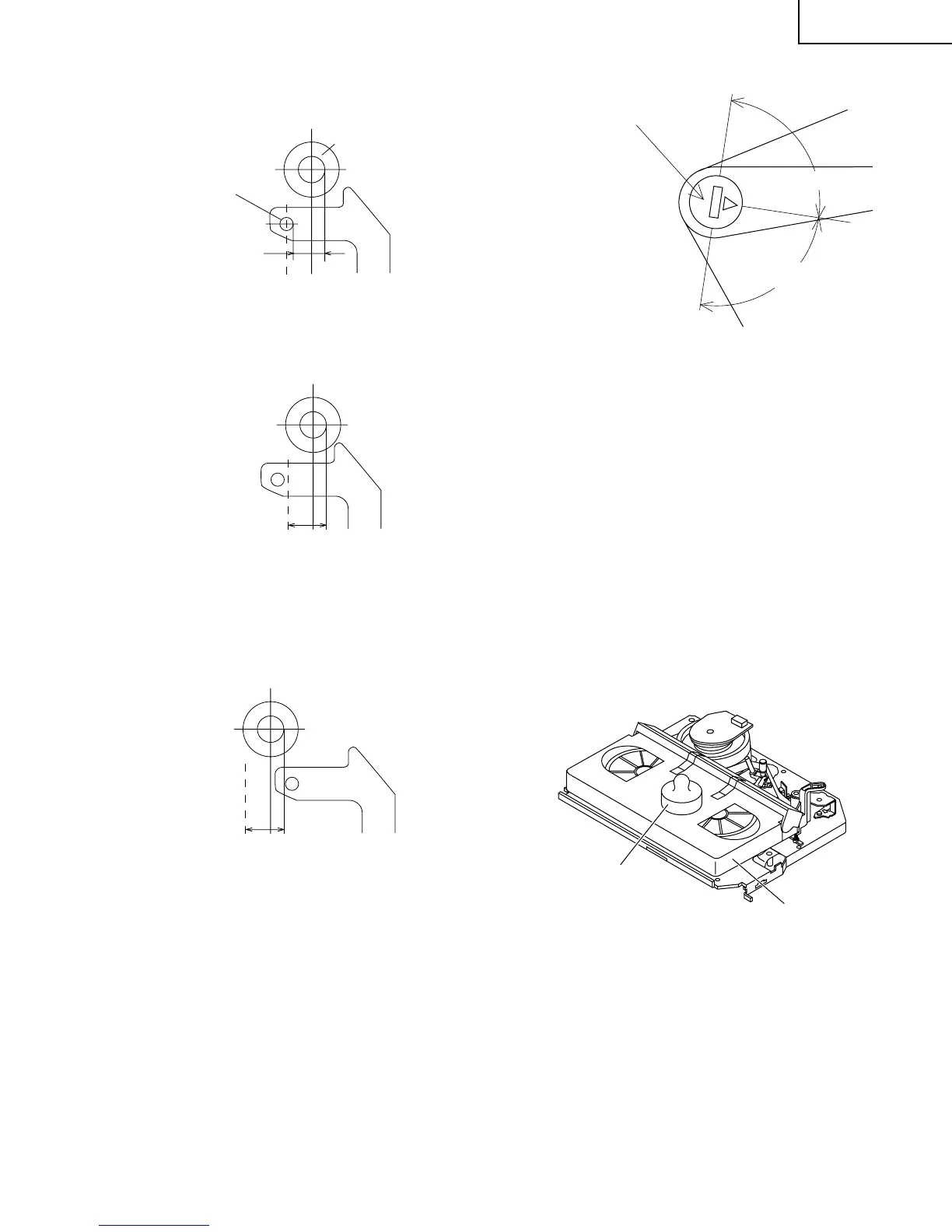

CHECKING AND ADJUSTMENT OF

RECORD/PLAYBACK BACK TENSION

• Remove the cassette housing control assembly.

• After short-circuiting R7057 and JUMPER:420

provided on the main PWB, plug in the power cord,

then turn off the power.

• Setting

1. Turn off the power switch.

2. Open the torque cassette meter and fix with tape.

3. Set the cassette tape into the unit.

4. Put the weight (500g) on the cassette torque meter.

5. Turn on the power switch.

500g

Weight to prevent

float (500g)

Cassette torque

meter

Figure 1-19.

• Checking

1. Push the REC button to place the unit in the SP record

mode.

2. At this time ascertain that the back tension is within the

setting (36.5 to 52g·cm) by seeing the indication of

torque cassette meter.

Loading...

Loading...