36

27DV-S100

27DV-CS10

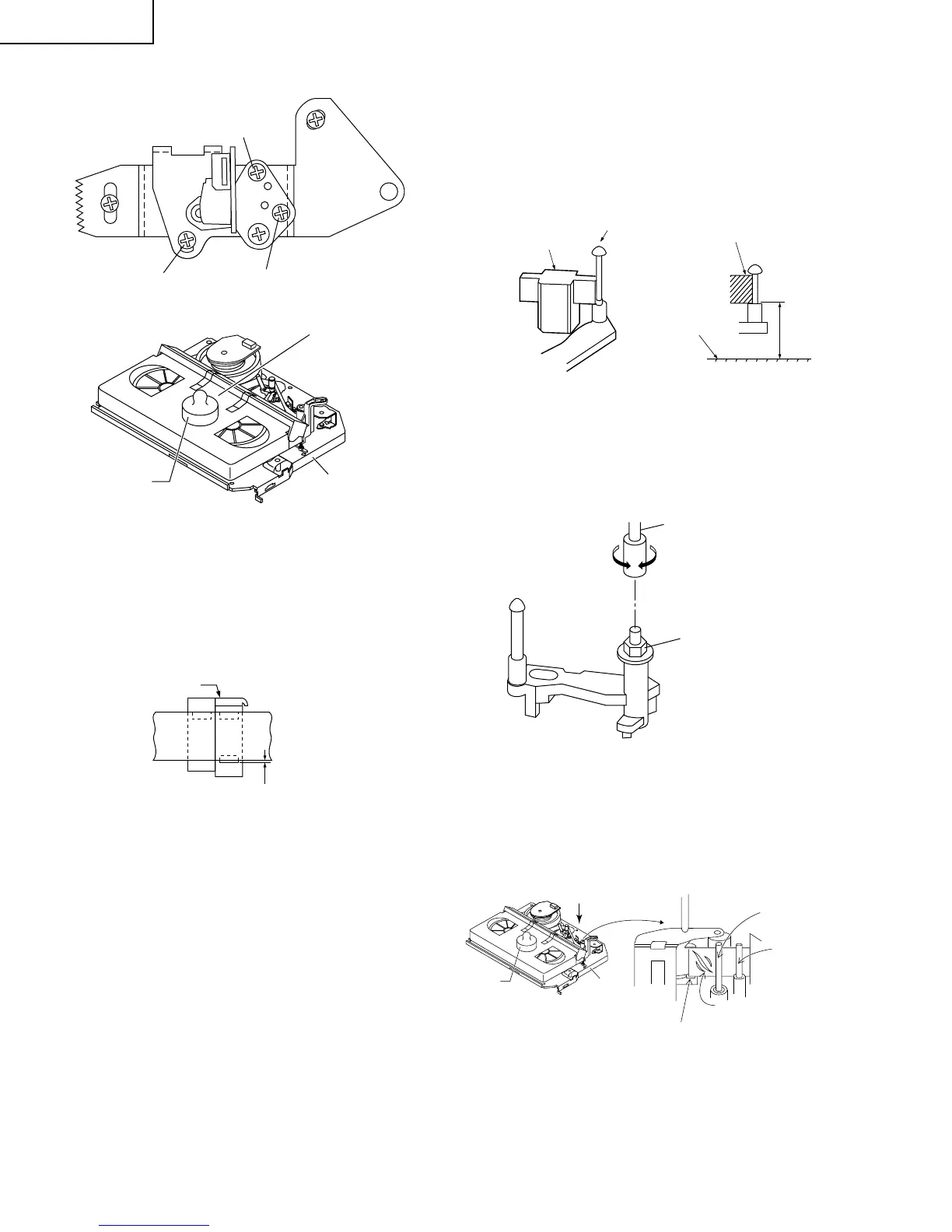

A/C HEAD HEIGHT ROUGH ADJUSTMENT

• Setting

1. Set the cassette tape in the unit.

2. Press the PLAY button to put the unit in the playback

mode.

3. Roughly adjust the height of the A/C head by turning

the height screw until the tape is in the position shown

below.

500g

Azimuth screw

Height screw

Tilt screw

Cassette tape

Mechanism chassis

Weight to prevent

float (500g)

Figure 1-26.

0.3mm

A/C head

Tape

• Adjustment

Adjust the height screw visually so that the control head is

visible 0.3mm below the bottom of the tape.

• Problems caused by maladjustments

1. Tapes may get scratched

2. Images onscreen distorted.

Figure 1-27.

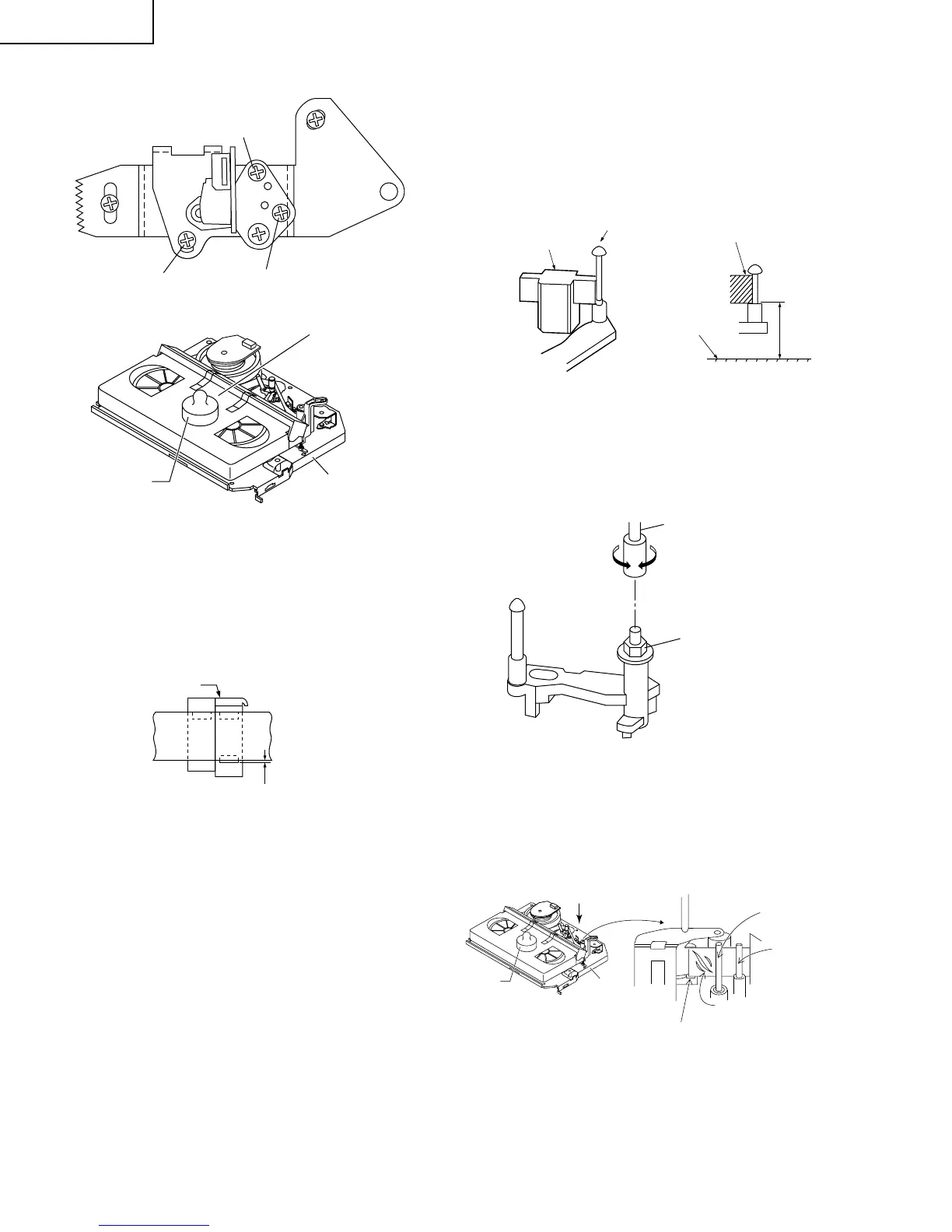

HEIGHT ADJUSTMENT OF REVERSE

GUIDE

1. Adjust the height from the mechanism chassis to the

reverse guide lower flange to 13.38 mm, using the

reverse guide height adjustment jig, in tape loading

state. (Refer to Figure 1-28 (a) (b).)

Reverse guide height

adjusting jig

Reverse guide

Mechanism

chassis

Reverse guide height

adjusting jig

13.38mm

Figure 1-28.

(a) (b)

2. Rotate counterclockwise the reverse guide height ad-

justment nut 1/10 turn. (For height adjustment use the

reverse guide height adjustment box driver (JiGDRiVER

11055)).

Box driver

CCW

Height adjusting nut

Figure 1-29.

3. Set the tape, and check for tape crease near the

reverse guide in the playback mode.

If crease is found, turn the reverse guide adjustment

nut to remove crease. (As for crease check refer to

Figure 1-30.)

500g

Weight to

prevent float (500g)

A

Capstan

motor shaft

Fixing guide

An example of

crease near the

reverse guide

Reverse guide

Mechanism

chassis

* Check for crease from the A direction.

Figure 1-30.

• Problems caused by maladjustments

1. Tapes may get scratched.

Loading...

Loading...